An automatic centering and clamping half-bridge welding device and welding method

An automatic centering and welding device technology, applied in welding equipment, auxiliary devices, tin feeding devices, etc., can solve the problems of easy waste products, troublesome installation and positioning process, high failure rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

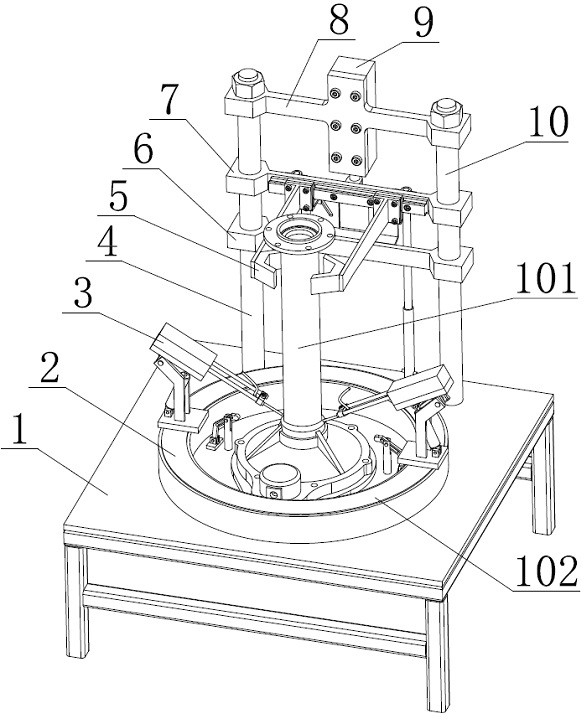

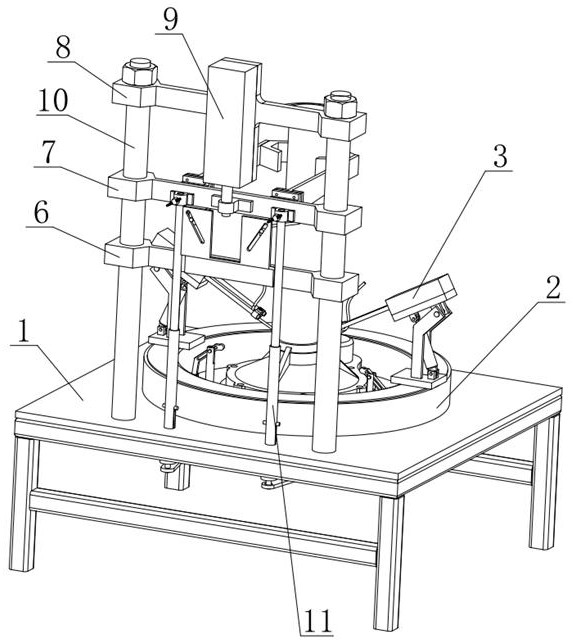

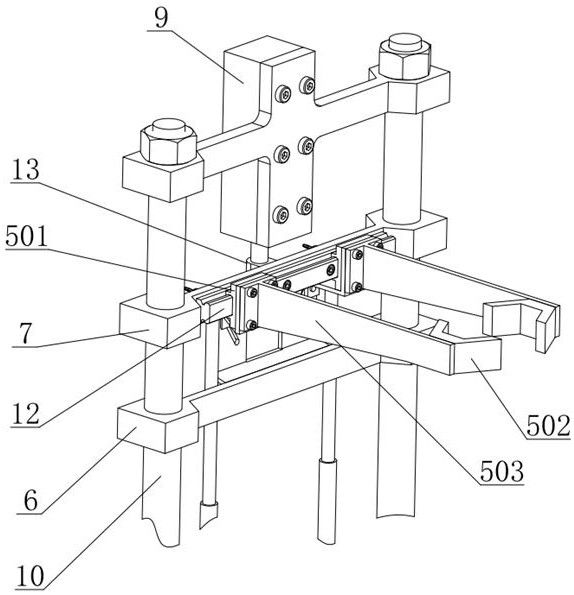

[0054] combine Figure 1-12 , an automatic centering and clamping half-bridge welding device of the present invention includes a base plate 1, an electric turntable 2, a left welding mechanism 3, a right welding mechanism, a left column 4, a left centering and pressing mechanism 5, Right centering pressing mechanism, lower fixing plate 6, sliding plate 7, upper fixing plate 8, lower pressure cylinder 9, right column 10, left axle housing pressing mechanism 11, right axle housing pressing mechanism, guide rail 12 , connecting seat 13, guide plate 14, axle housing positioning plate 15, control system, with the operator being located in the position facing the bridge tube 101 and the down-press cylinder 9, defining the application with the operator's up and down, left and right, front and rear directions Up and down, left and right, front and rear directions, in order to describe the application. The base plate 1 has a left-right symmetrical structure, the left axle housing pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com