Impact adjustable internal puller

An adjustable, inner-pulling device technology, used in hand-held tools, manufacturing tools, etc., can solve problems such as easily damaged bearings or sheaths, unbalanced strength, and difficulty in starting, and achieves reduced risk, balanced strength, and acceptable strength. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

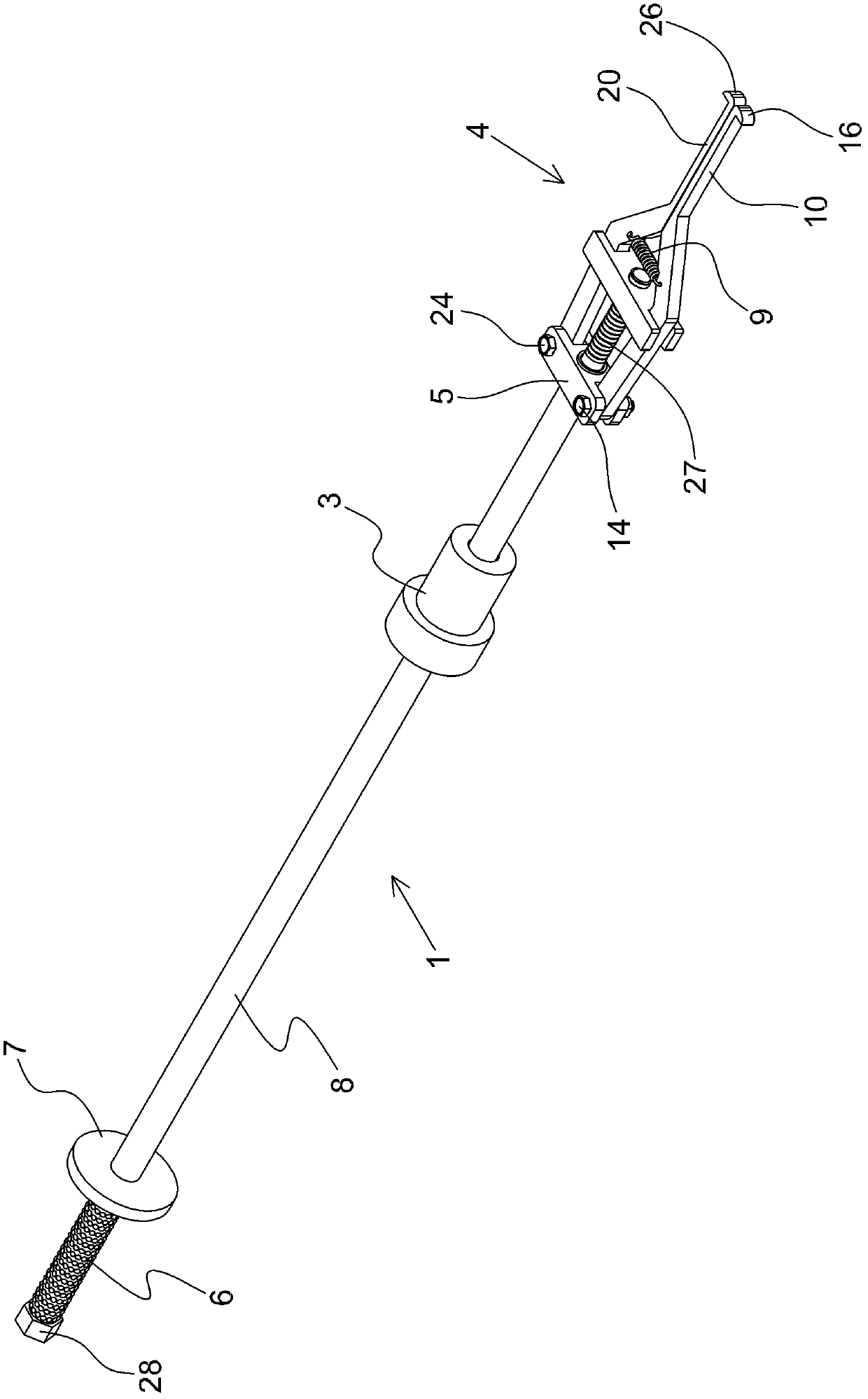

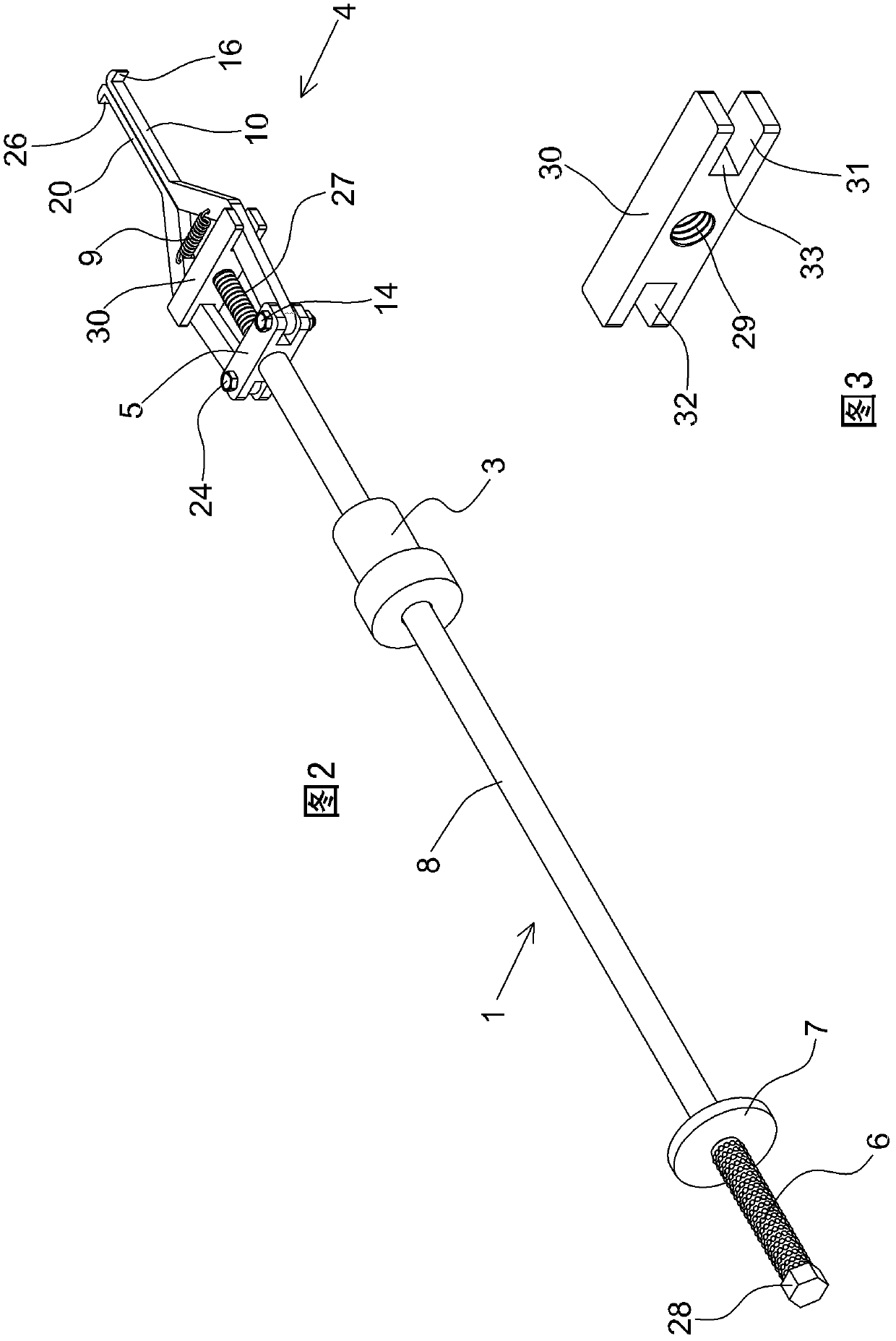

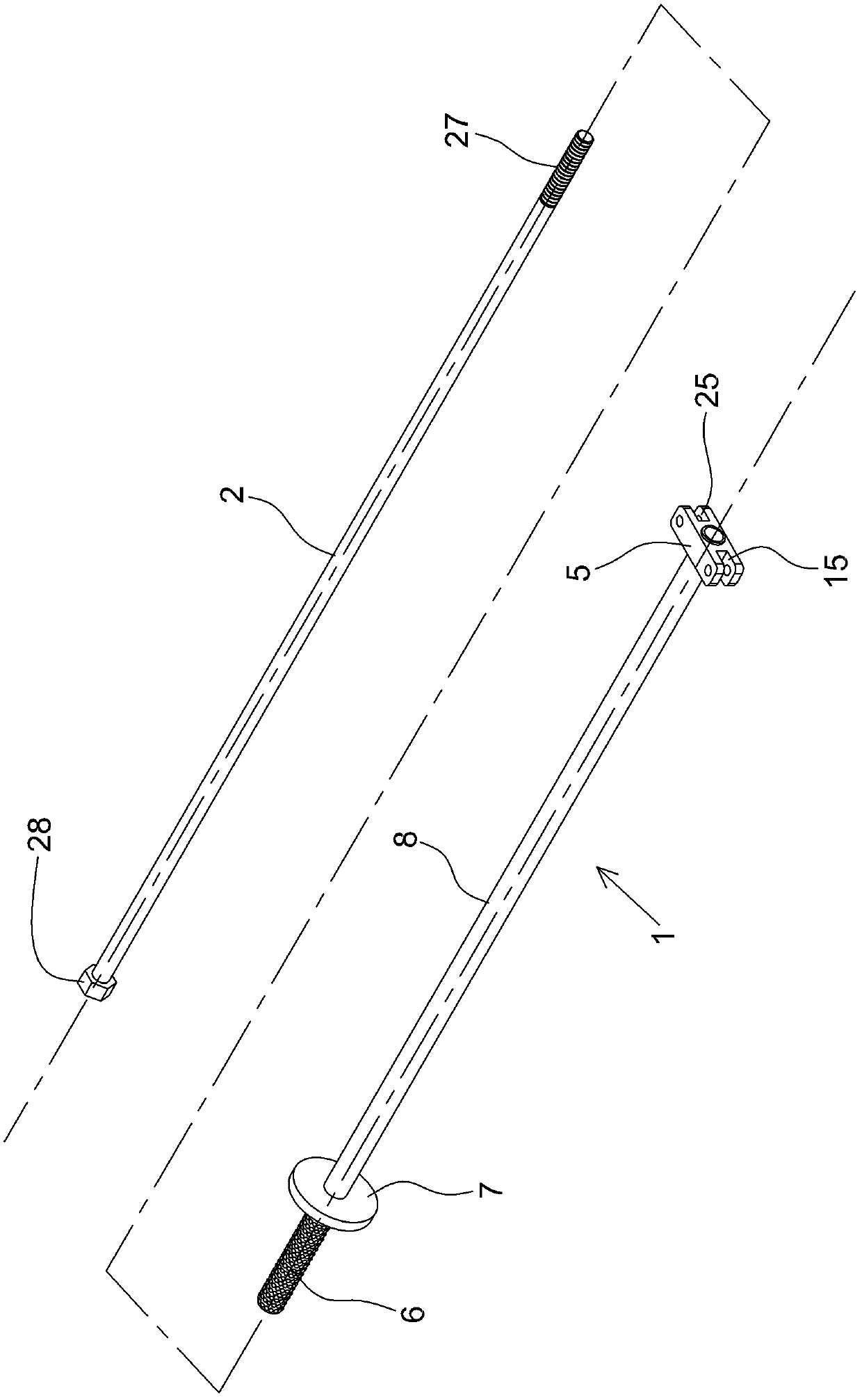

[0019] Label in the figure

[0020] 1 handle rod 2 adjustment rod 3 impact hammer 4 jaw assembly

[0021] 5 support frame 6 handle 7 fixed disc 8 polished rod part

[0022] 9 Extension spring 10 Left claw 11 Upper arm section 12 Middle arm section

[0023] 13 Lower arm section 14 Pin shaft 15 Left ear seat 16 Left claw hook

[0024] 17 Bearing 18 Inner ring hole 19 Sheath 20 Right claw

[0025] 21 upper arm section 22 middle arm section 23 lower arm section 24 pin shaft

[0026] 25 Right ear seat 26 Right claw hook 27 Thread head 28 Hex nut

[0027] 29 threaded hole 30 tensioning slider 31 left groove 32 right groove

[0028] 33 inner end face 34 inner end face

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention is an impact-type adjustable inner puller, which is composed of a handle rod 1, an adjustment rod 2, an impact hammer 3, and a claw assembly 4. The handle rod 1 is composed of a hollow tube, and the front end of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com