Thread disassembly device of extruder screw rod for thermosetting powder coating

A technology of thermosetting powder and disassembly device, which is applied in the field of screw tooth disassembly device, can solve the problems of gas and open fire safety hazards, damage to the mechanical properties of the screw, low disassembly efficiency, etc., to avoid mechanical properties, improve disassembly efficiency, and the use process is simple and can be used. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

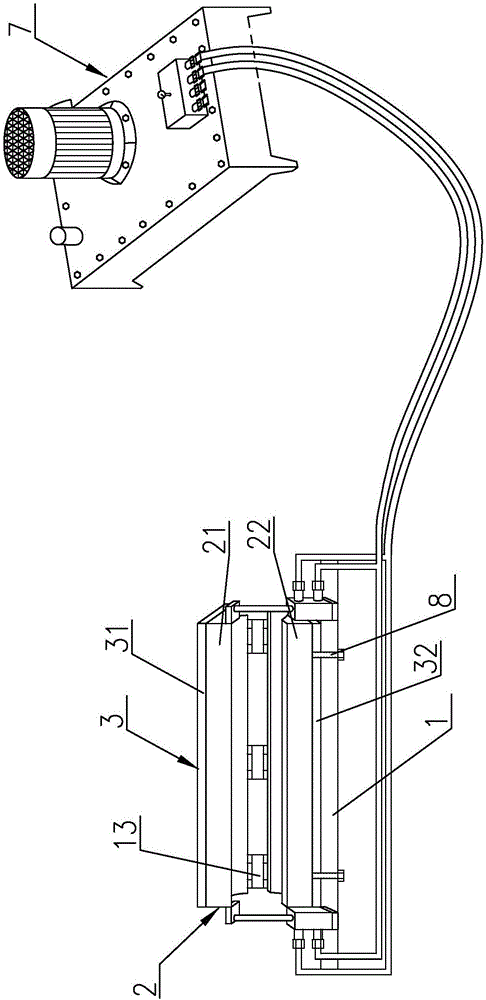

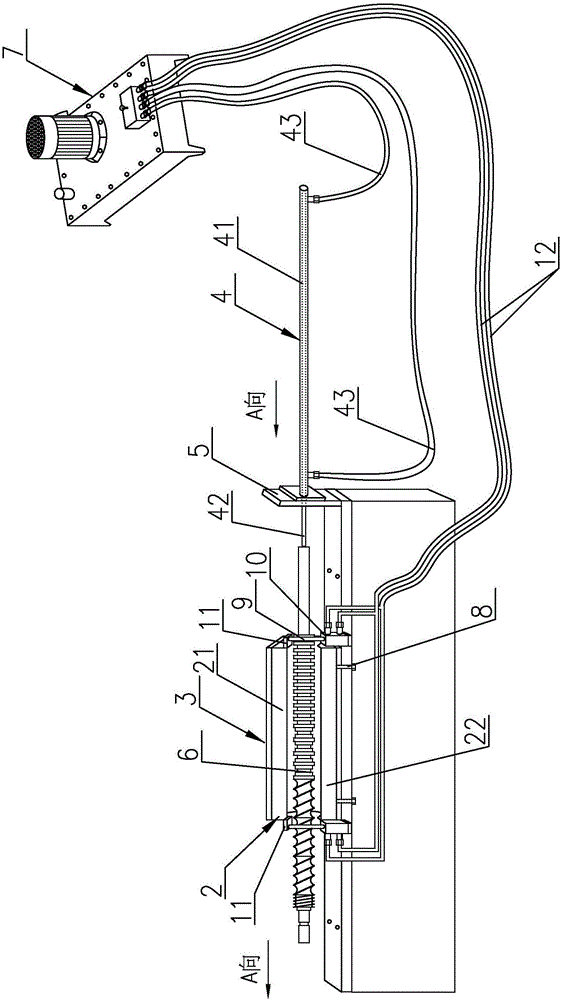

[0027] like figure 1 and 2 Shown is a thread removal device for extruder screws for thermosetting powder coatings of the present invention, which includes an electric control device, a support 1, a clamp 2, an electric heating system 3, an opening and closing mechanism, a push rod 4, and a push rod The support frame 5 and the driving mechanism 7, the clamp 2 is a horizontally arranged cylinder, the electric heating system 3 is installed on the clamp 2, the internal space of the cylinder is adapted to the screw rod 6 to be disassembled and the screw rod 6 to be disassembled is tightly clamped therein , the cylinder body is mainly composed of the upper half cylinder body 21 and the lower half cylinder body 22 hinged on their respective sides through the hinge 13, the lower half cylinder body 22 is arranged on the top surface of the support 1, and on the upper half cylinder body 21 and the two ends of the other side of the lower half cylinder 22 are provided with an opening and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com