Extra-high voltage reference capacitor

A standard capacitor and ultra-high voltage technology, applied in capacitors, instruments, electrical components, etc., can solve problems such as easy displacement, increased voltage coefficient, uneven distribution of local electric field, etc., and achieve the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

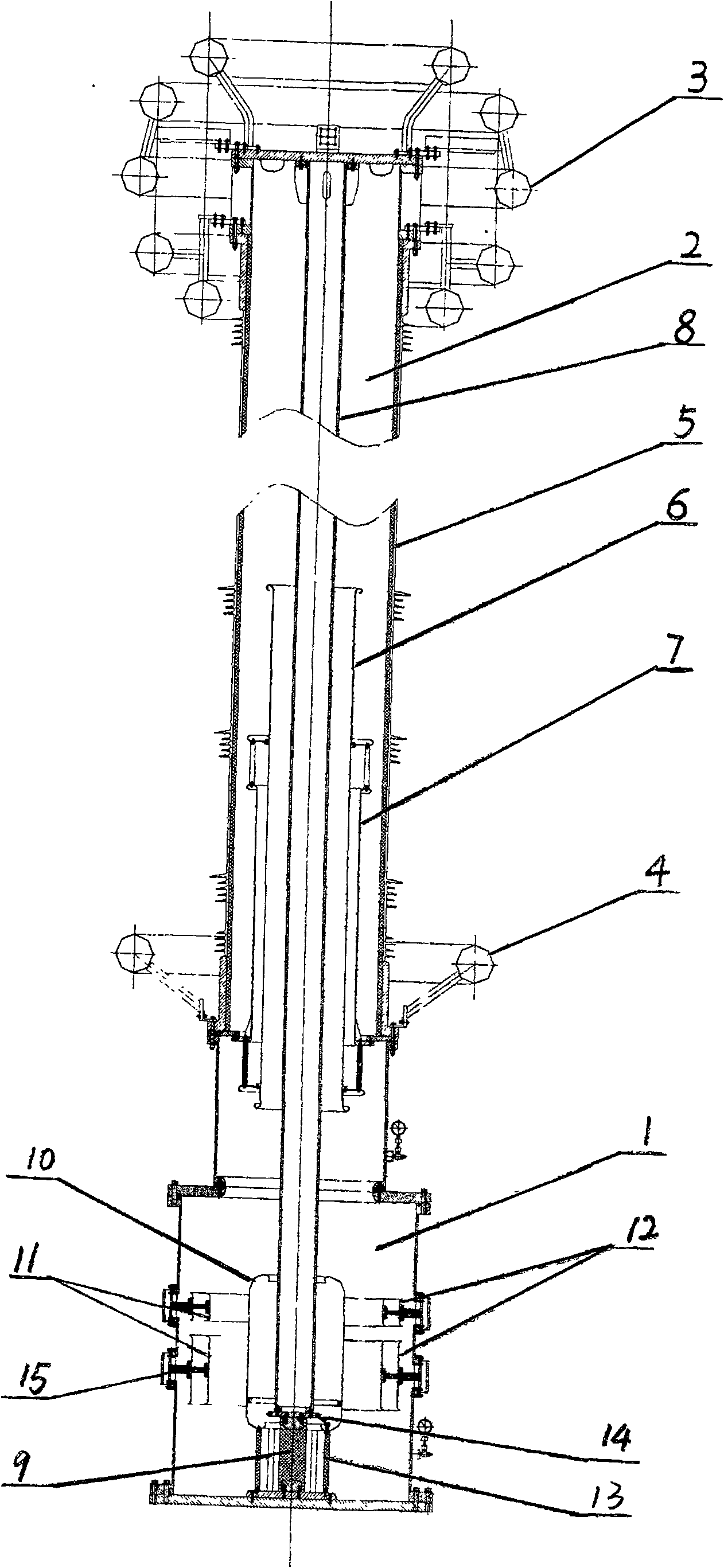

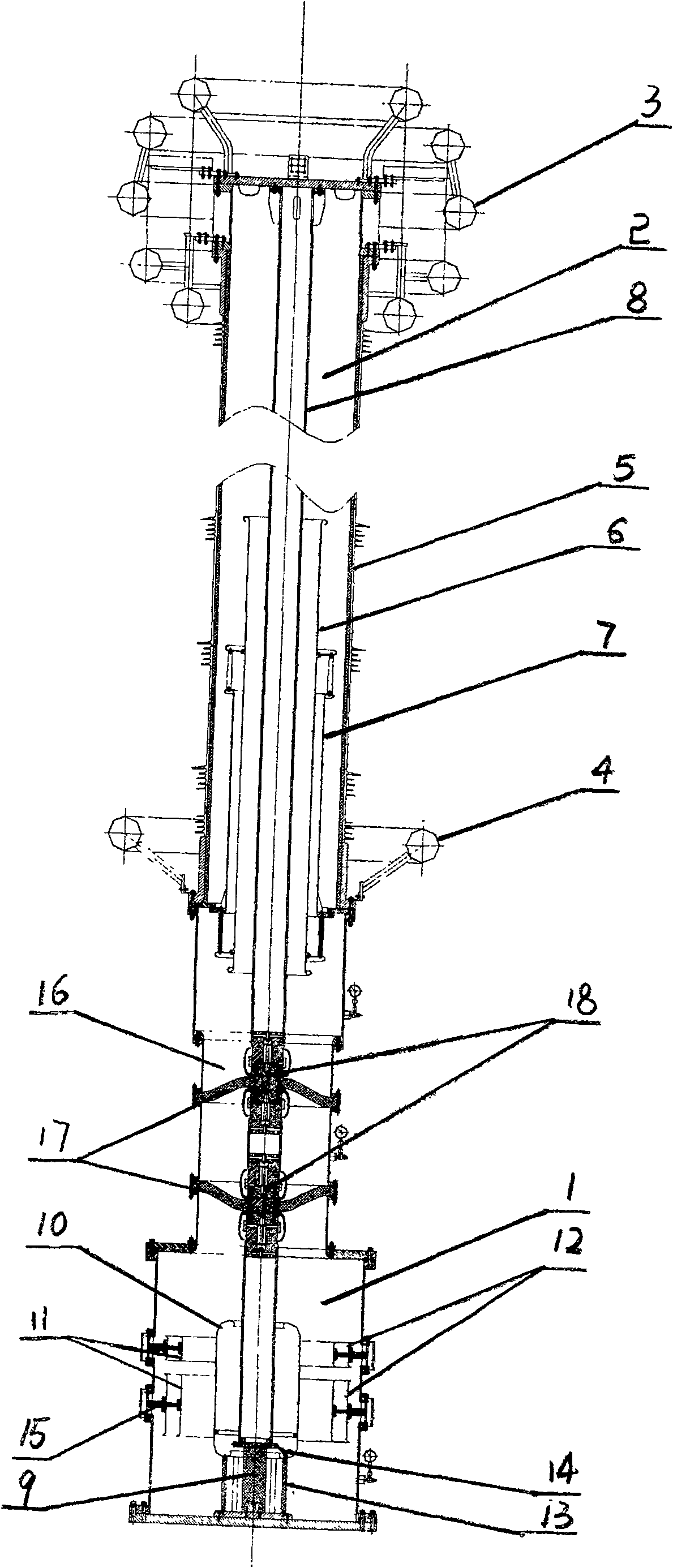

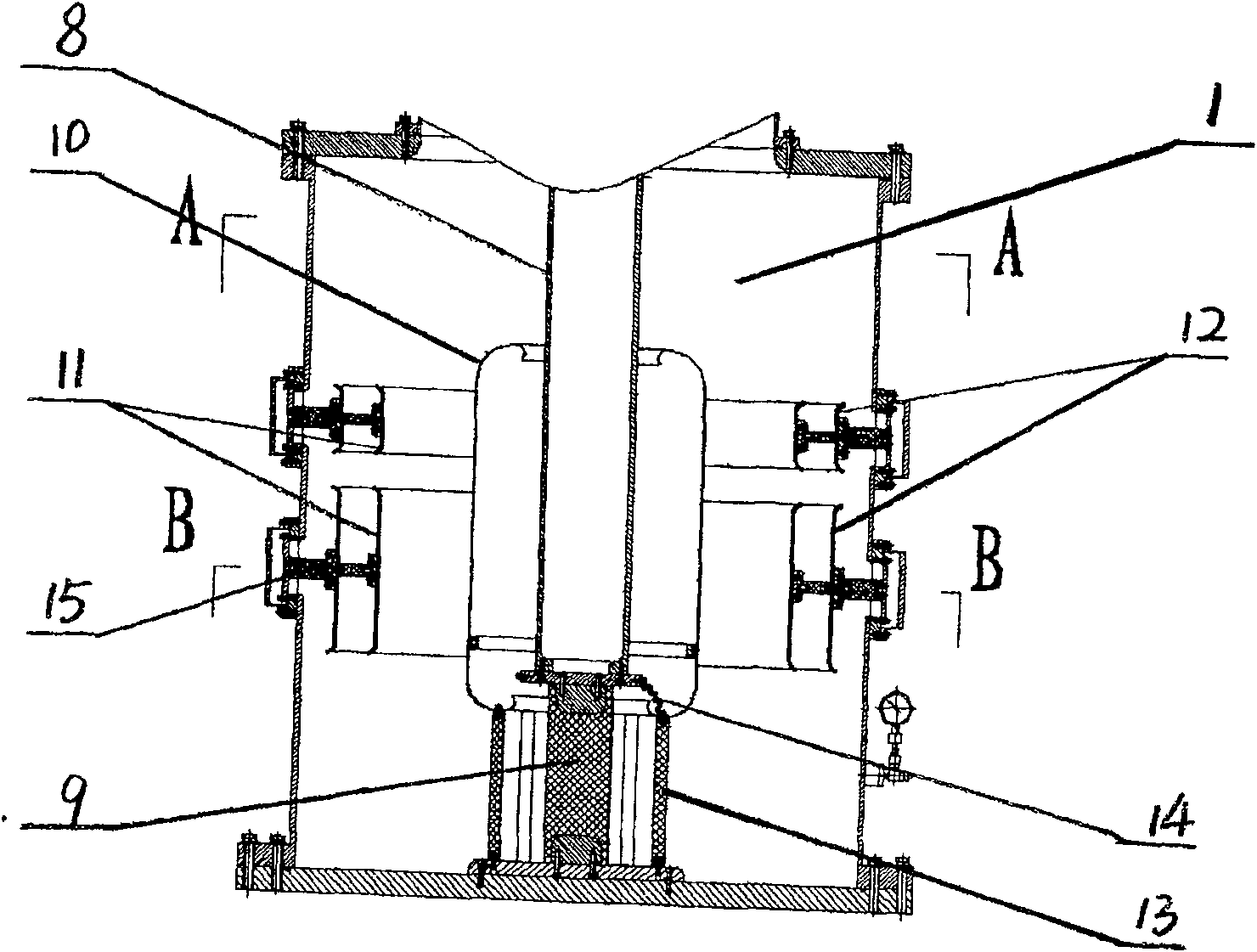

[0015] figure 1 It is a structural diagram of a gas chamber of the present invention. The present invention is a UHV standard capacitor with an upright structure in which both the high-voltage electrode and the low-voltage electrode are fixed in the bottom SF6 gas-insulated pressure vessel tank with insulating supports. body 1, high voltage bushing 2, high voltage equalizing ring 3 and ground potential equalizing ring 4, the inside of the tank is filled with SF 6 Gas insulation, the high-voltage bushing 2 is above the tank body 1, the high-voltage equalizing ring 3 and the ground potential equalizing ring 4 are at both ends of the high-voltage bushing 2; the high-voltage bushing 2 is composed of a composite insulating bushing 5 and an intermediate potential shield 6 , the ground potential shielding cover 7 and the high voltage electrode tube 8 are combined, and the lower end of the high voltage electrode tube 8 is fixed on the center of the base in the tank body 1 through an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com