Assembly and disassembly tooling and method for engine piston ring

A technology for piston rings and engines, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of poor control of the opening range of piston rings, poor support of piston rings, and unsuitable installation of piston rings, etc., to achieve high disassembly efficiency , Simple structure, high assembly and disassembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

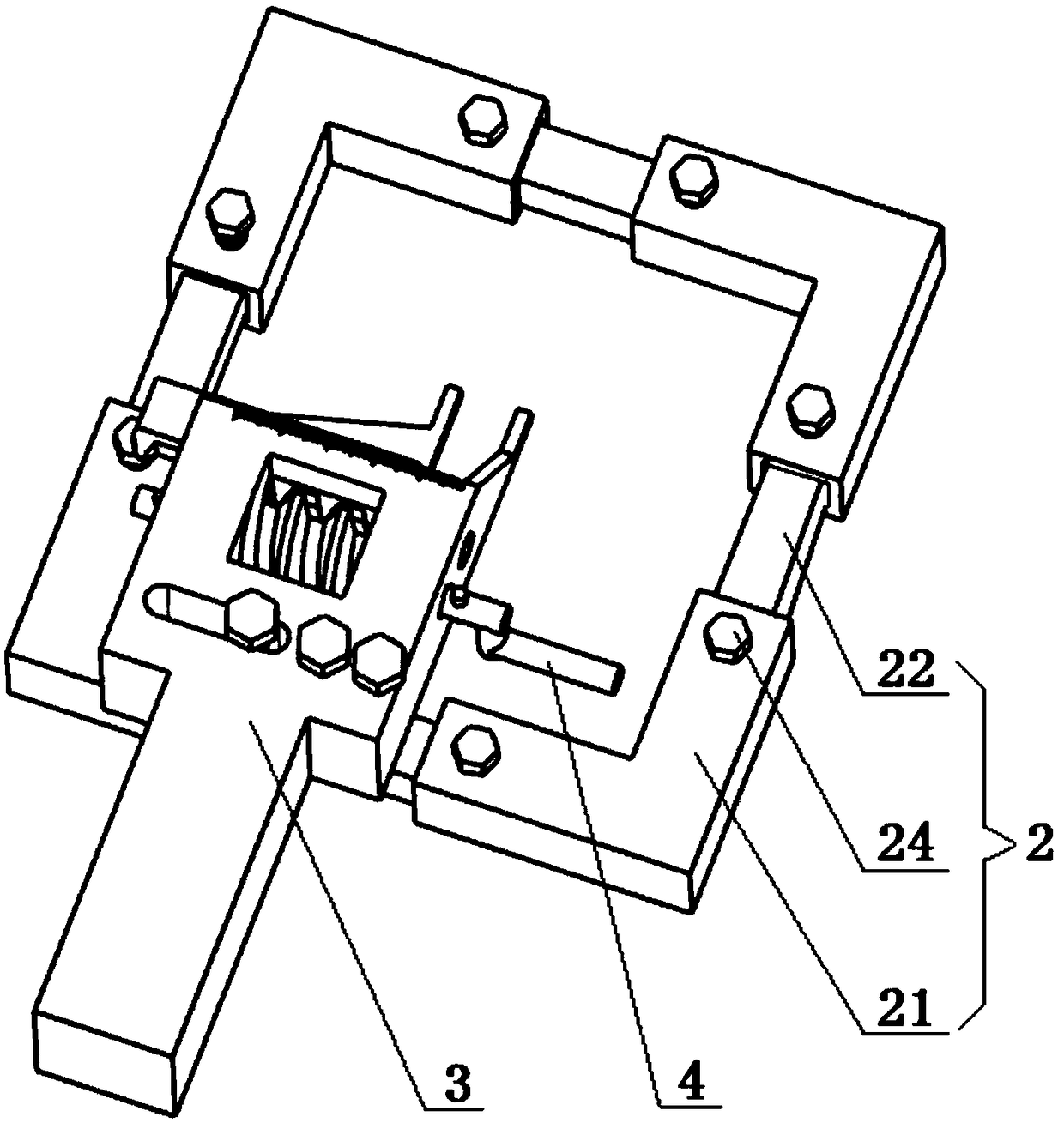

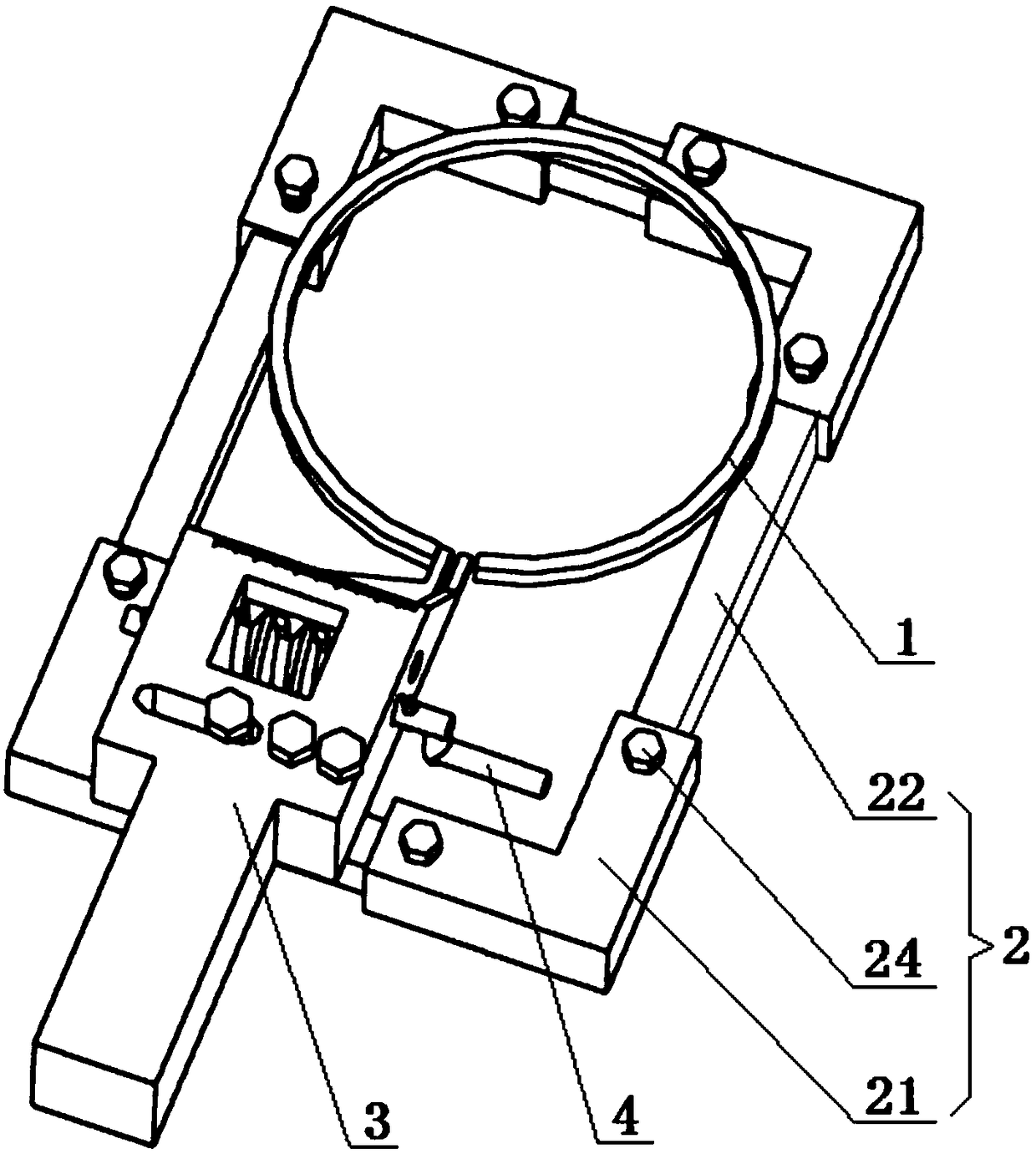

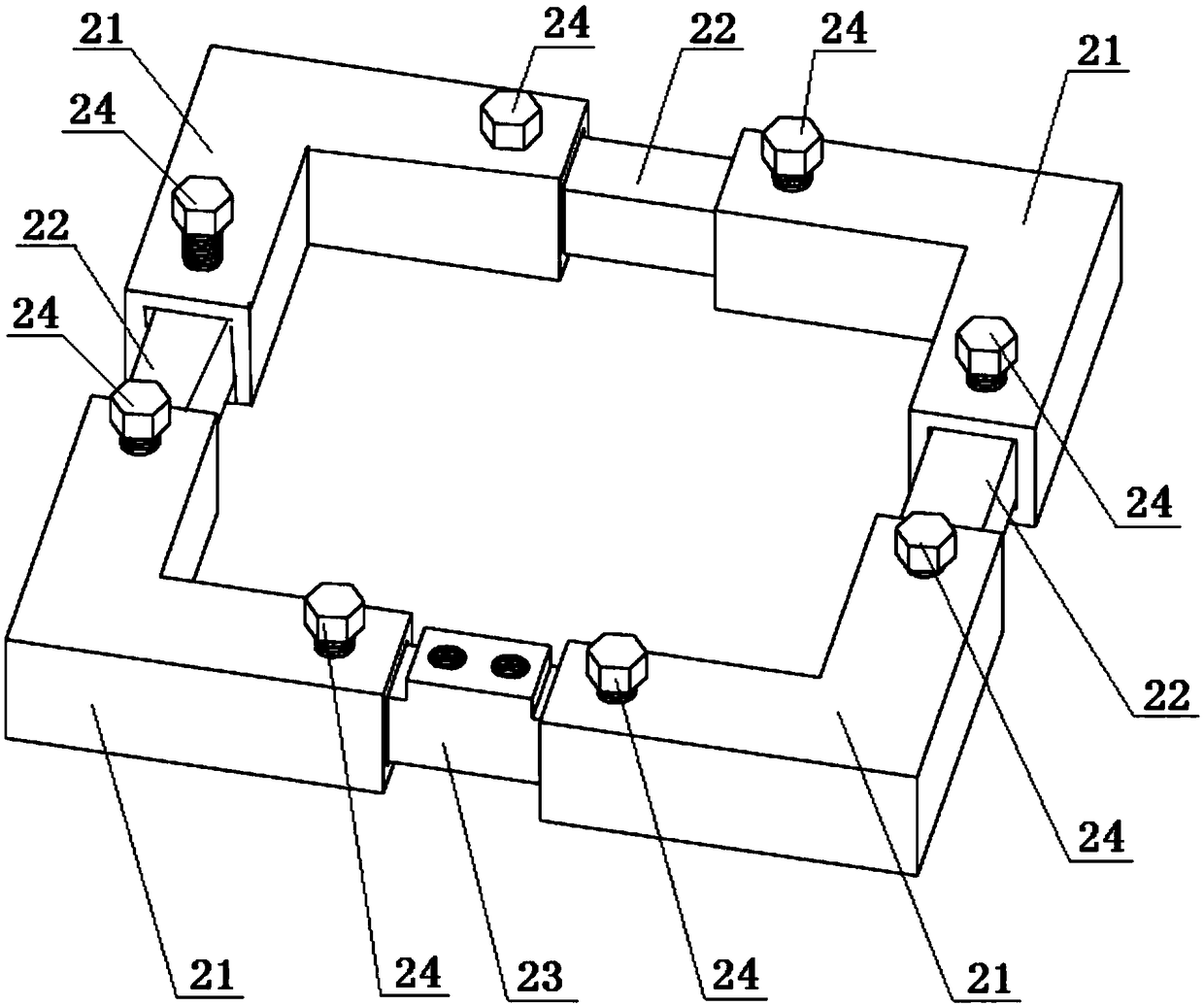

[0040] refer to Figure 1-9 , an engine piston ring assembly and disassembly tooling of the present invention, including a telescopic support frame 2 for supporting and positioning the piston ring 1 and adjusting its width to adapt to piston rings 1 with different diameters, and a telescopic support frame 2 located above the support frame 2 and connected with it The connected opening mechanism 3 for opening the piston ring 1 can be inserted into the opening of the piston ring 1. The opening mechanism 3 is provided with a device that can drive the opening mechanism 3 to open slowly at a constant speed so that the opening of the piston ring 1 opens. Drive mechanism 4. The invention has a simple structure, uses the adjustable support frame 2 to support and position the piston ring 1, and opens the piston ring 1 through the force generated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com