Pretensioner for form cable

A pre-tensioning and formwork technology, which is used in the connection of formwork/formwork/work frame, the on-site preparation of building components, construction, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

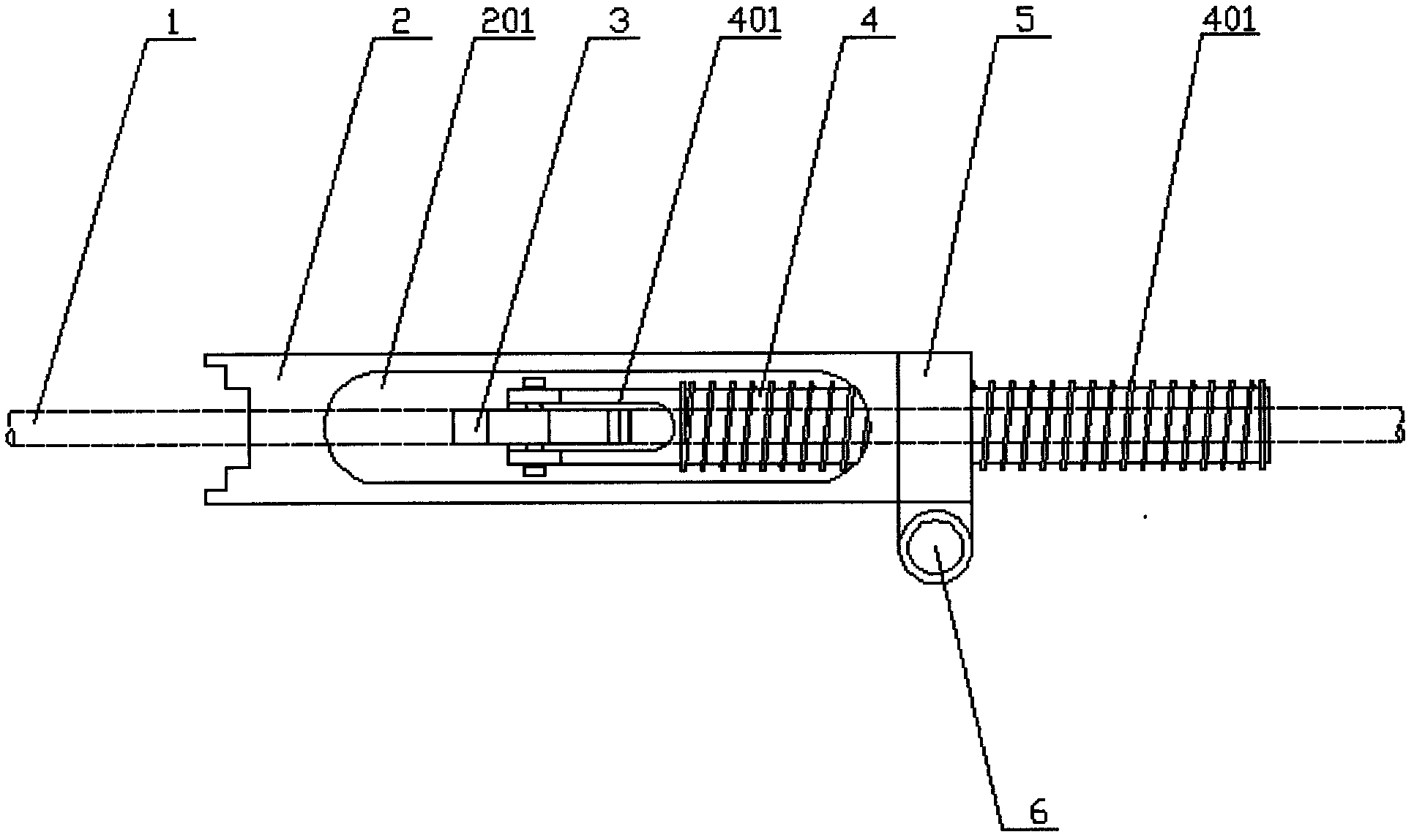

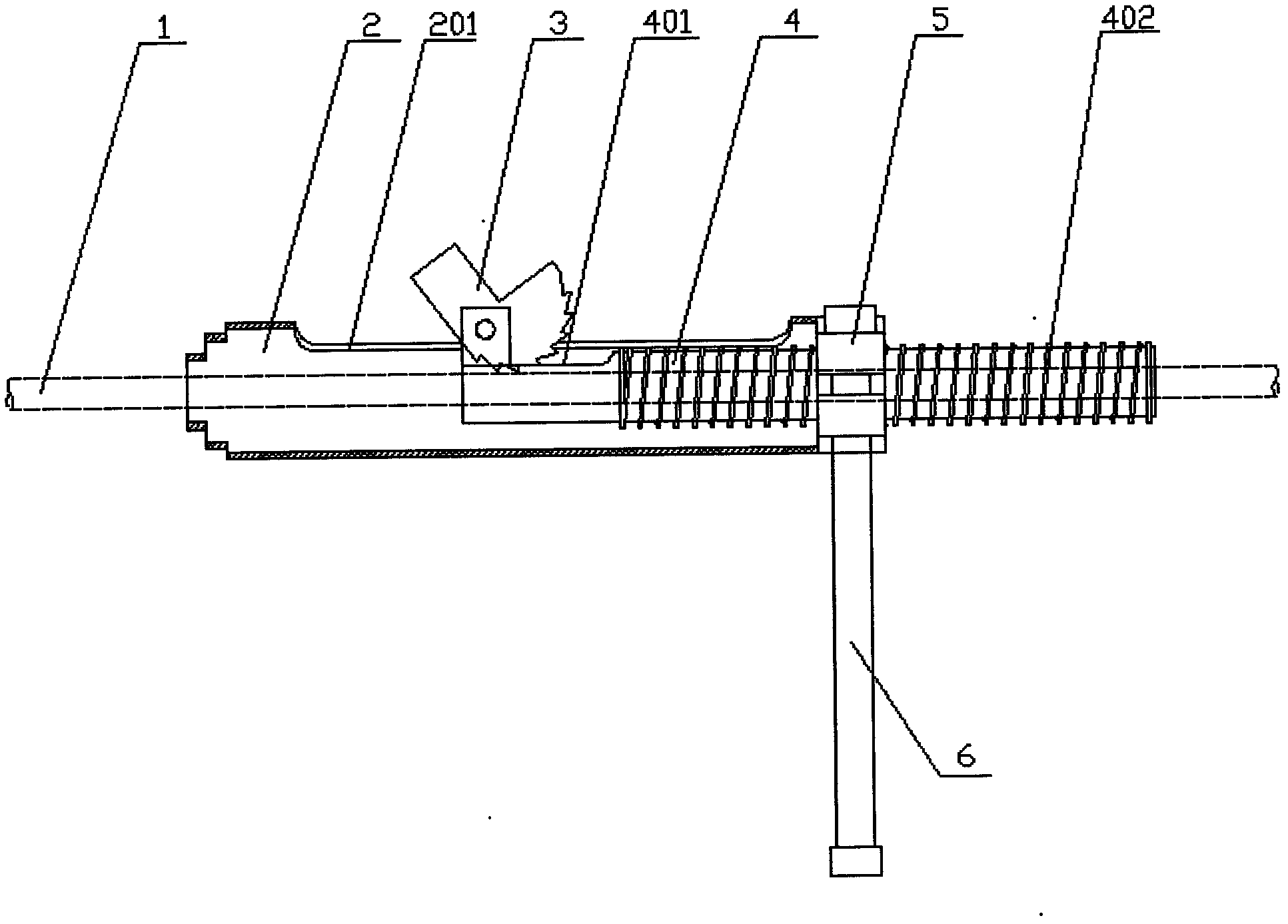

[0016] figure 1 It is a formwork cable pretensioning device, which consists of an outer sleeve 2, an inner sleeve 4, a crescent gauge 3, a handle cap 5 and a handle 6.

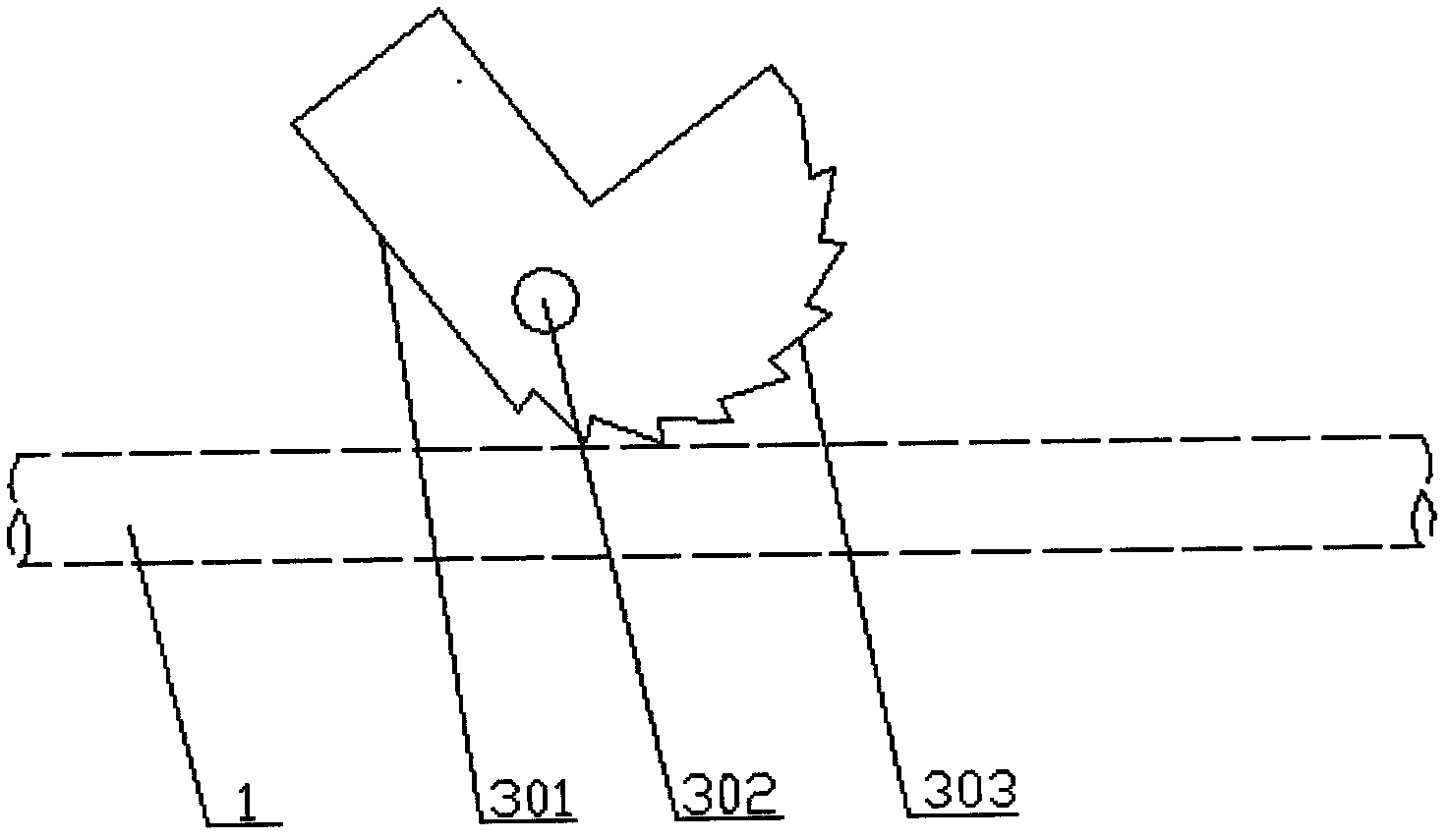

[0017] exist figure 2 Among them, the inner sleeve 4 and the outer sleeve 2 are hollow cylinders, the inner diameter of the outer sleeve 2 is greater than the outer diameter of the inner sleeve 4, and the middle part of the outer sleeve is provided with a strip-shaped slot 201, and the inner sleeve 4 The upper part is provided with an external thread 402, and the lower part of the inner sleeve is provided with a bar-shaped slot 401. The inner sleeve 4 is set in the outer sleeve 2, and the upper part of the inner sleeve protrudes from the upper end of the outer sleeve. The handle cap 5 is provided with an internal thread and is threadedly connected with the protruding end of the inner sleeve 4. The handle cap 5 is provided with a handle jack, the handle 6 is inserted in the jack and can slide in the jack, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com