Multipurpose hoisting frame

A No. 1, hook technology, applied in the field of multi-purpose hangers, can solve the problems of high labor intensity, hidden safety hazards, disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

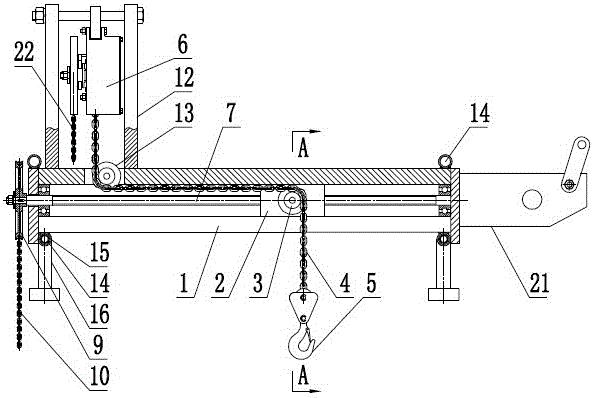

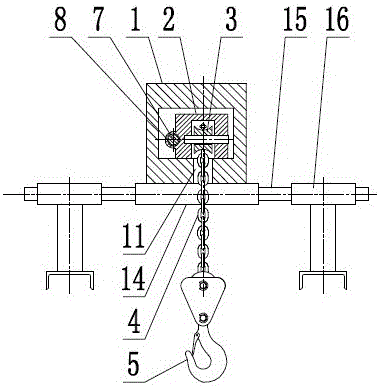

[0028] Embodiment one, such as figure 1 , figure 2 As shown, a kind of multi-purpose hanger comprises cross beam 1, and described cross beam 1 is provided with slide block 2 that can slide axially along cross beam 1, and described slide block 2 is equipped with a No. 1 pulley 3, and described No. 1 pulley 3 A hoisting chain 4 is wound around it, and one end of the hoisting chain 4 is connected to a hook 5 , and the other end is connected to a manual hoist 6 . The beam 1 of the first embodiment is placed above the gearbox, the manual hoist 6 is used as the power to hoist the gearbox, the height difference between the beam and the hook 5 is reduced by the No. 1 pulley 3, and the gearbox is moved by the horizontal movement of the slider 2. To the outside of the vehicle, the whole process can be completed by only one person, which is easy, fast and safe, and is especially suitable for the disassembly and assembly of large vehicle gearboxes in the field environment.

[0029] Emb...

Embodiment 2

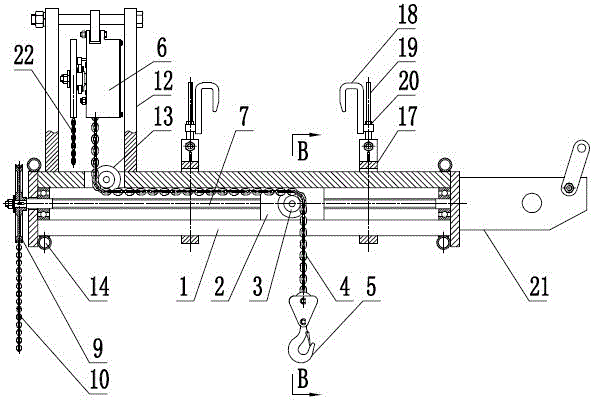

[0034] Embodiment two, such as image 3 , Figure 4 As shown, at least two lifting buckles 17 movable in the axial direction are provided on the outside of the beam 1 , and a height-adjustable hook 18 is arranged above the lifting buckles 17 . The hoisting buckle 17 of the second embodiment is slidable, and the height of the hook 18 is adjustable. It is suitable for a gearbox with a mandrel on the top. The hook 18 is hung on the mandrel to complete the fixed installation of the beam 1 .

[0035] Embodiment two, such as image 3 , Figure 4 As shown, a screw 19 is hinged above the hoisting buckle 17, and a hook 18 and a stop nut 20 are sequentially mounted on the screw 19. In the second embodiment, other structures can also be selected to realize the adjustment of the height of the hook 18 .

Embodiment 3

[0036] Embodiment three, such as Figure 5 As shown, the suspension hook 5 is a double-chain suspension hook. Compared with the single-chain hook, the double-chain hook of Embodiment 3 is more labor-saving, and is suitable for particularly heavy gearboxes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com