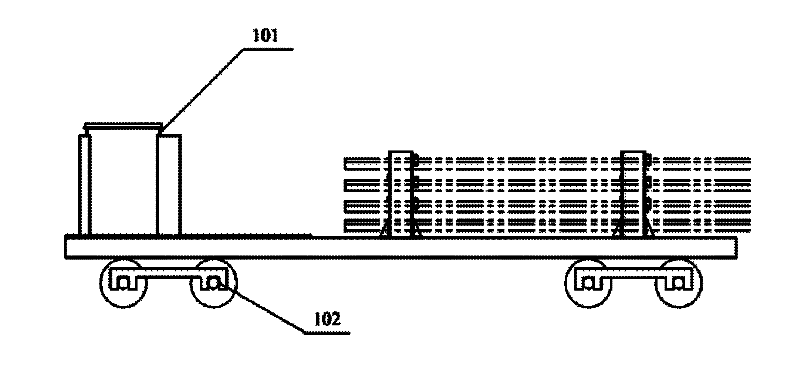

Security vehicle for long rail train set and long rail train set

A technology for safety cars and train sets, applied in freight cars, passenger cars, railway car body parts, etc., can solve problems such as increased derailment, uneven loading of bogies, and increased vehicle maintenance costs, so as to reduce the possibility of derailment. , Eliminate the phenomenon of partial wear and improve the effect of running quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

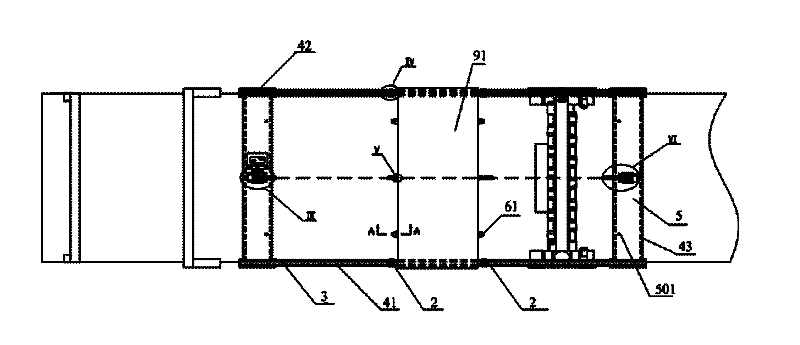

[0028] The "longitudinal" mentioned herein refers to the longitudinal direction of the long rail train set, "transverse" refers to the direction perpendicular to the "longitudinal" in the horizontal plane, and "front" refers to the train running direction. Of course, "front" and "Rear" is relative, and when the train runs in reverse, the positions of "front" and "rear" are exchanged.

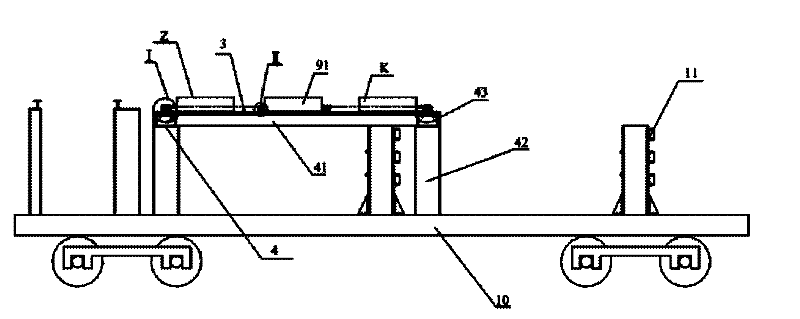

[0029] The present embodiment provides a kind of safety car of long rail train set, please refer to figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , including: a safety car body 10 extending longitudinally, the upper surface of the safety car body 10 is fixedly provided with a mounting frame 11 for loading long rails, at a first distance from the upper surface of the safety car body, and at the safety Both sides of the vehicle body are respectively provided with guide rails 3 extending longitudinally, and the guide rails 3 are fixedly connected with the safety vehicle body 10 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com