Screw rod for pushing trolley

A technology of screw and trolley, which is applied in the direction of packaging, etc., can solve the problems of difficult welding of fan-shaped plates, high cost, and difficulty in welding spiral strip plates, and achieves the effects of easy support, simple operation, and simple and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

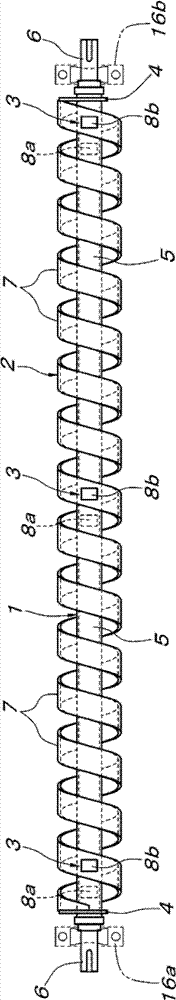

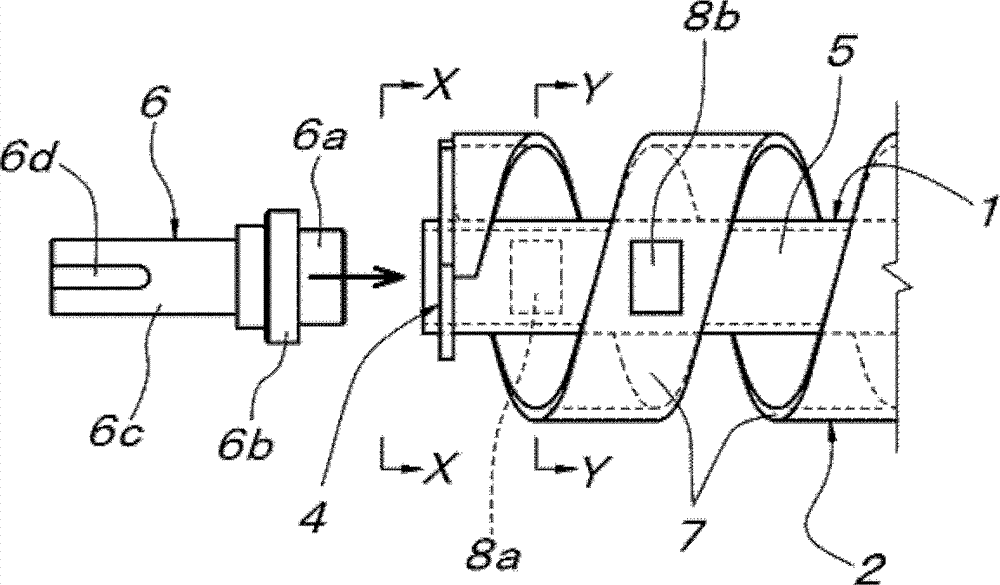

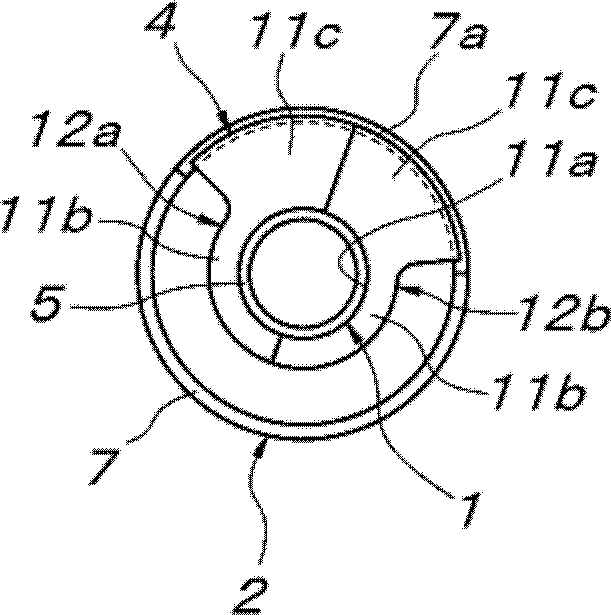

[0048] Figure 1A to Figure 2B Among them, 1 is a drive shaft, 2 is a cylindrical screw body, 3 is a connecting member, and 4 is an end plate. The drive shaft 1 is composed of a cylindrical body 5 that is slightly longer than the overall length of the cylindrical screw body 2, and an end shaft body 6 that is concentrically fixed to both ends of the cylindrical body and protrudes from both ends of the cylindrical screw body 2. . The end shaft body 6 is composed of a fitting portion 6a embedded in the end of the cylindrical body 5, a large-diameter collar portion 6b connected to the end of the cylindrical body 5, and a small-diameter shaft body 6c having a keyway 6d. constituted. The fitting part 6a is inserted into the end of the cylindrical body 5, and the cylindrical body 5 and the end shaft body 6 are integrated by welding in a state where the large-diameter collar portion 6b is in contact with the end of the cylindrical body 5.

[0049]The cylindrical screw body 2 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com