Lifting hooks for plate type catalyst unit block

A technology of catalyst and unit block, which is applied in the field of machinery, can solve the problems of easily damaged catalyst plates and consumption, and achieve the effects of saving reserved space, smooth lifting, and reducing stagnant vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

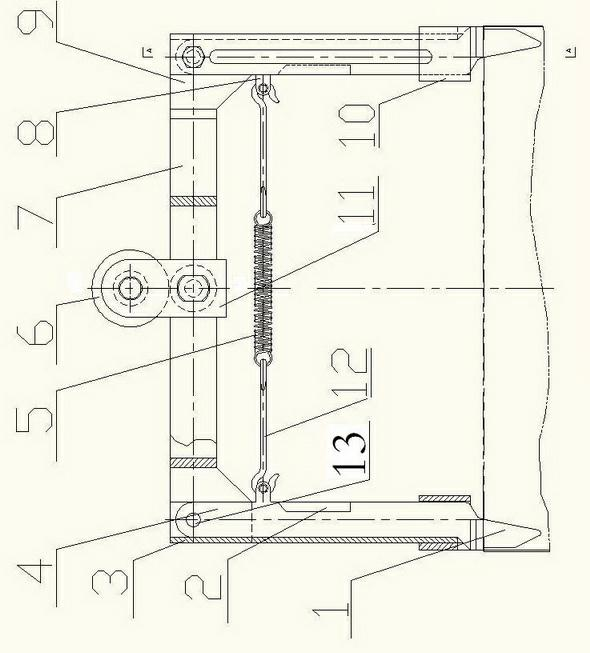

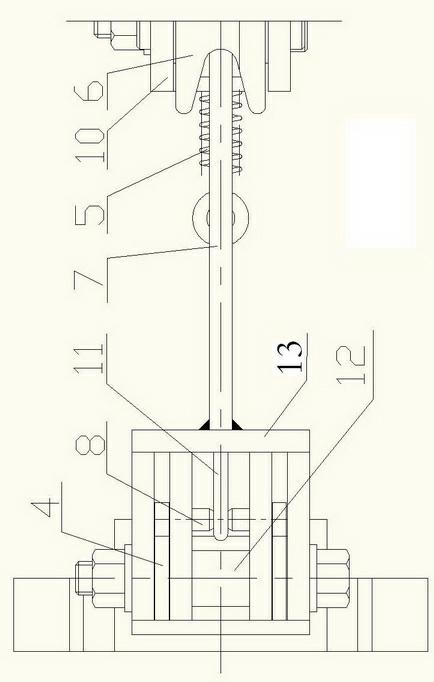

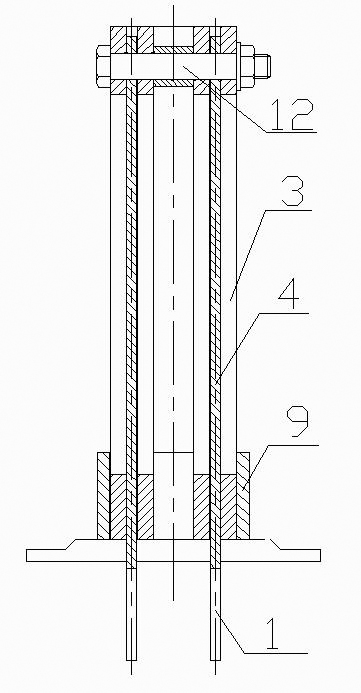

[0011] The hanging beam 7 of the present invention is fixedly installed on the hanger 9, the suspension hook 4 is connected on the hanger 9 by the shaft 13, the outside of the suspension hook 4 has a hook body protection groove 3 fixedly installed on the hanger 9, and the bottom of the suspension hook 4 A hook tongue 1 is installed at the end; the 6 shafts of the sheave are connected to the protective frame 11, and the protective frame 11 is fixedly installed on the suspension beam 7; there is a lock sleeve card slot 2 on the suspension hook 4; On the hook seat 8 on the hook 4; the knuckle lock sleeve 10 is sleeved on the suspension hook 4 and the suspension hook body protection groove 3.

[0012] In the middle part of the present invention, a sheave is connected to a main girder through the "sheave and protective frame". The bodies are placed in parallel in their respective grooves. When the rope pulley drives the main beam to rise, the knuckle catches the workpiece and rises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com