Automatic furnace-entering heating and automatic exiting mechanism for glass bars

A technology of automatic withdrawal and glass rod, which is applied in the field of auto parts manufacturing, can solve the problems of high cost of transformation, waste, and large heat energy, etc., and achieve the effect of reducing the cost of transformation and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

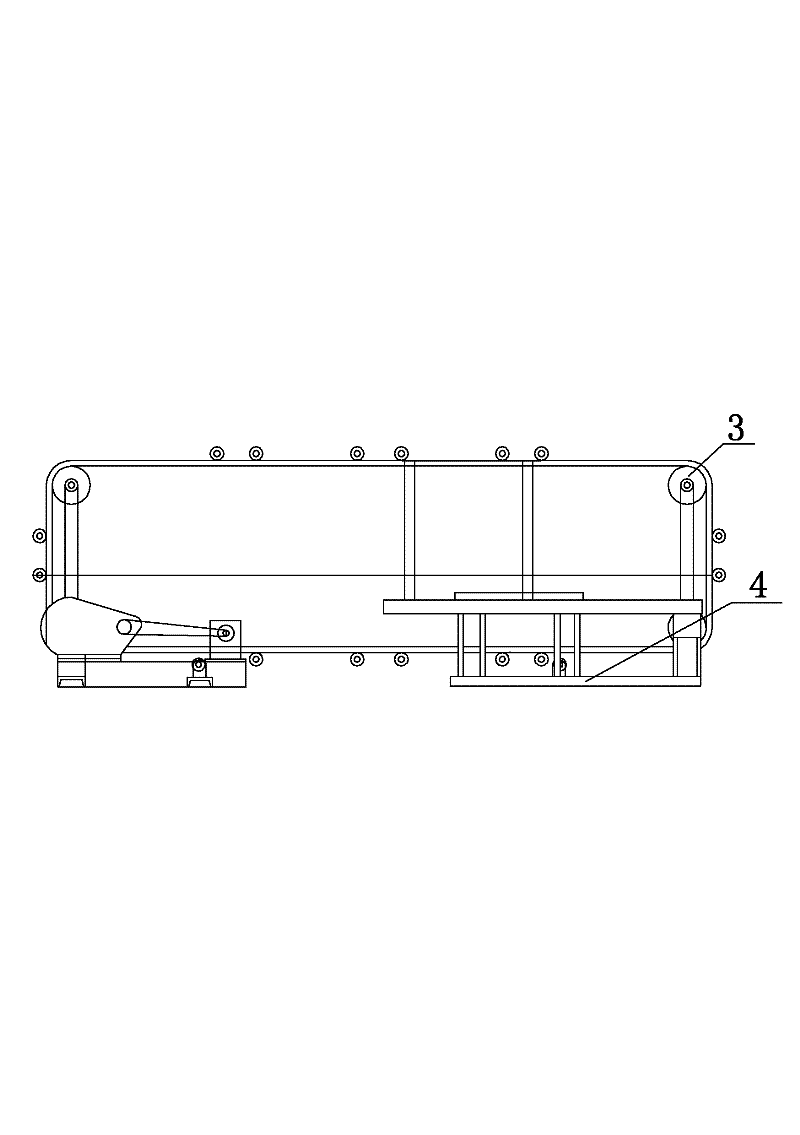

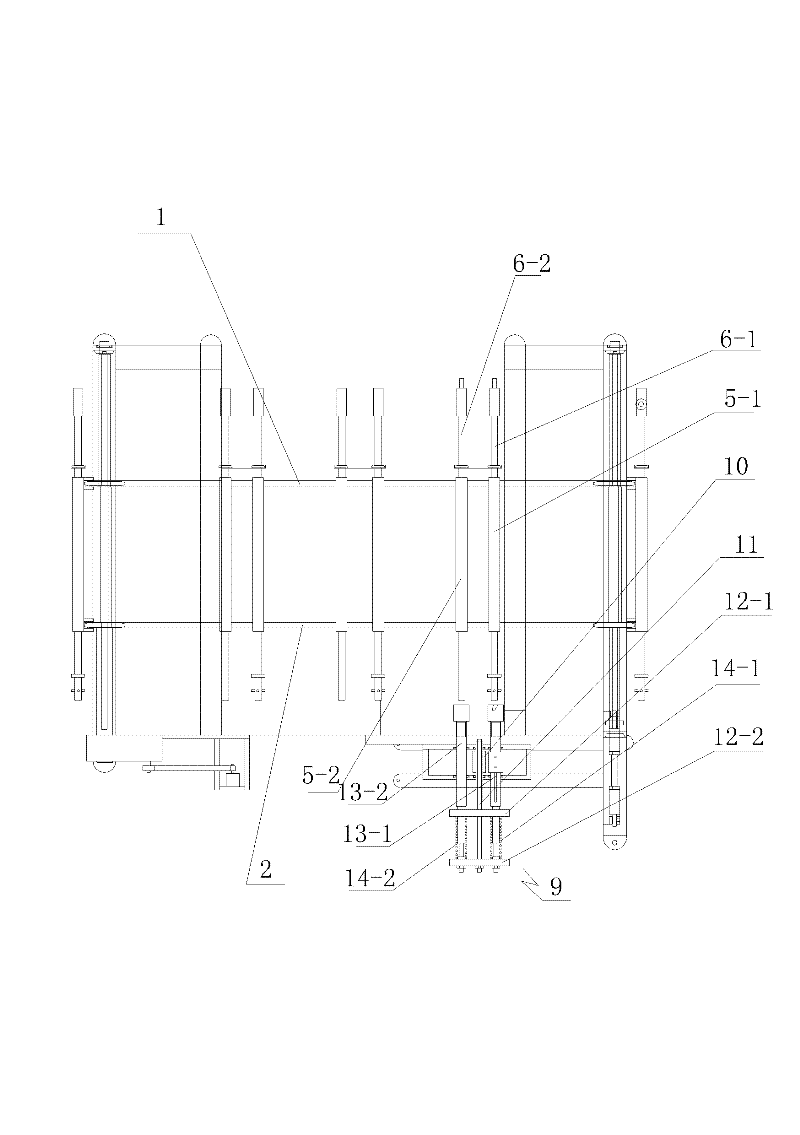

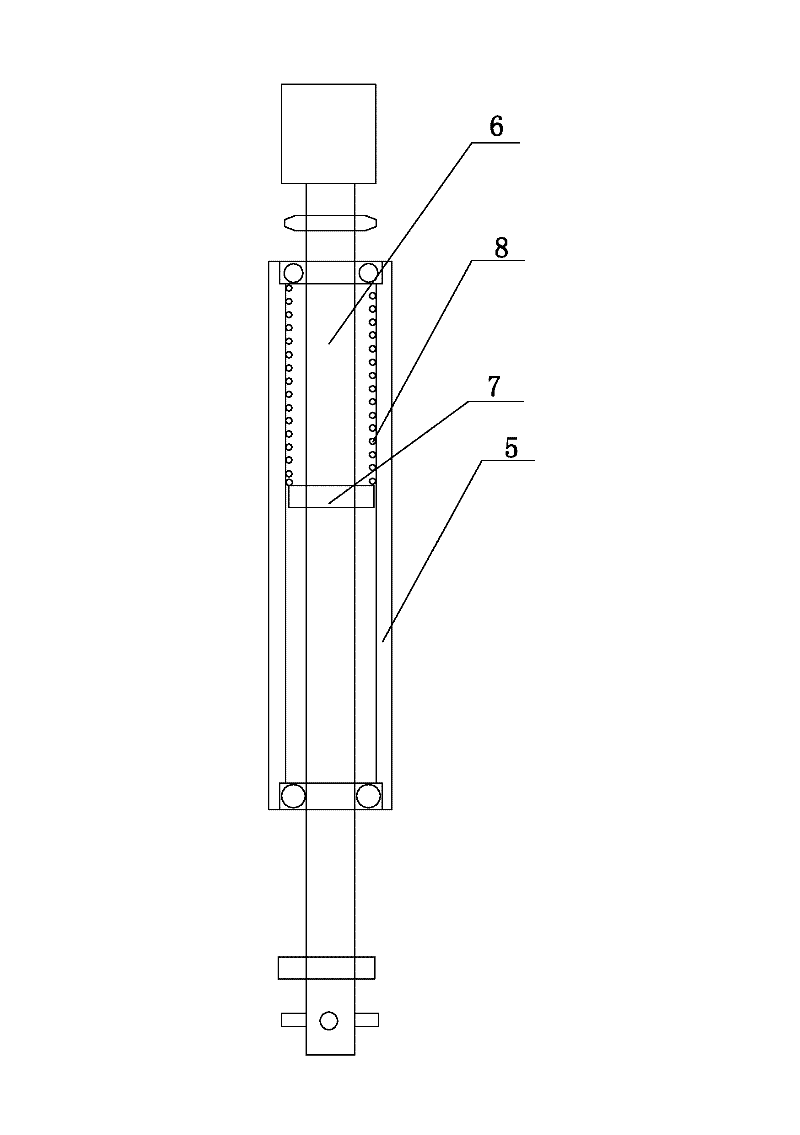

[0010] See figure 1 , figure 2 , image 3 , an automatic furnace heating and automatic exit mechanism for glass rods, which includes double crawlers 1, 2, crawlers 1, 2 are supported on a support frame 4 by crawler wheels 3, and fixed crawler sleeves 5-1, 5-2 are arranged on On crawlers 1 and 2, telescopic seamless pipes 6-1 and 6-2 are movably arranged in fixed crawler covers 5-1 and 5-2 respectively. Spring seat 7 is fixed on telescopic seamless pipe 6, and one end of spring 8 supports On the spring seat 7, the other end is fixed in the fixed crawler cover, and one end of the telescopic seamless pipe 6-1, 6-2 is provided with a propulsion device 9, and the propulsion device 9 includes a driving motor 10, and the driving motor 10 is connected to a rotating screw rod 11 , the rotating screw 11 is respectively connected to push the seamless pipes 13-1, 13-2 through the two-layer synchronous plates 12-1, 12-2; a spring 14-1 is arranged between the two-layer synchronous plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com