Ultra-low viscosity pressure-sensitive adhesive

A pressure-sensitive adhesive and sticky technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems that there are no reports on the application of ultra-low-viscosity pressure-sensitive adhesives, and the ultra-low-viscosity target cannot be achieved. To achieve the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

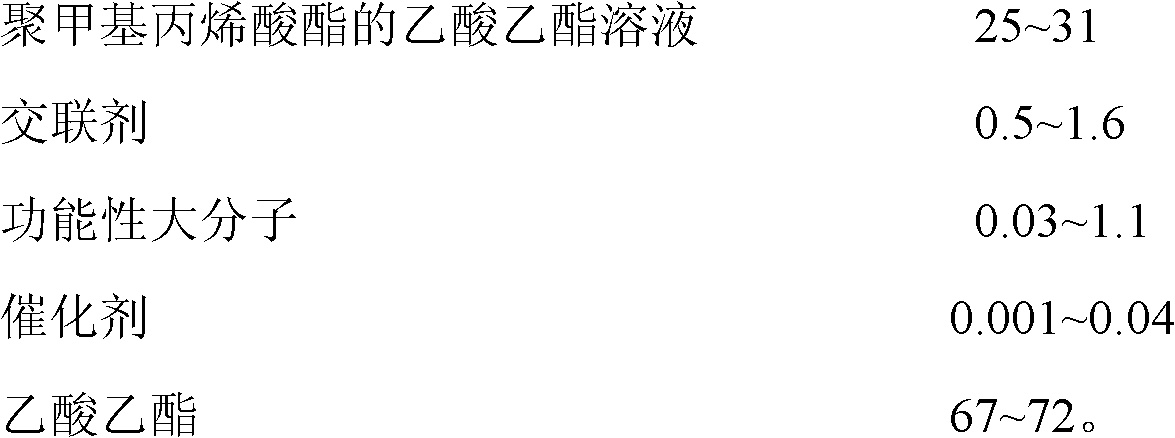

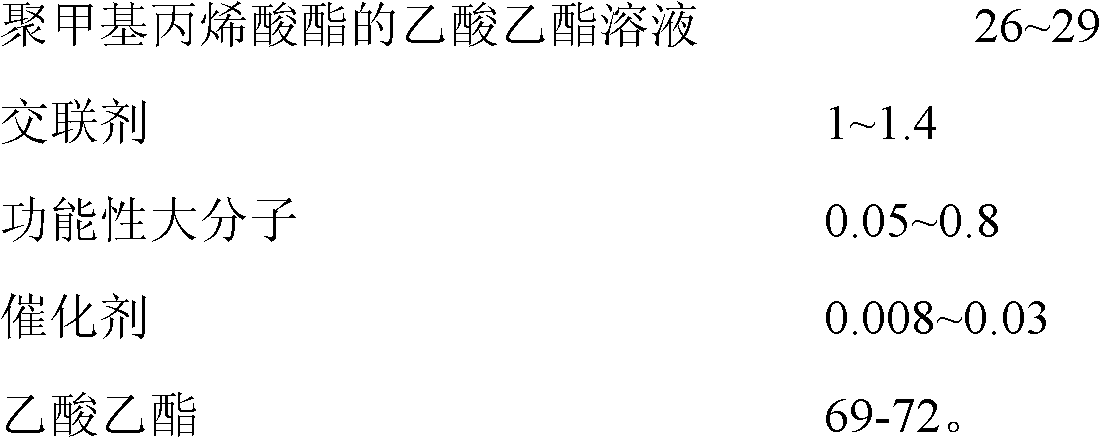

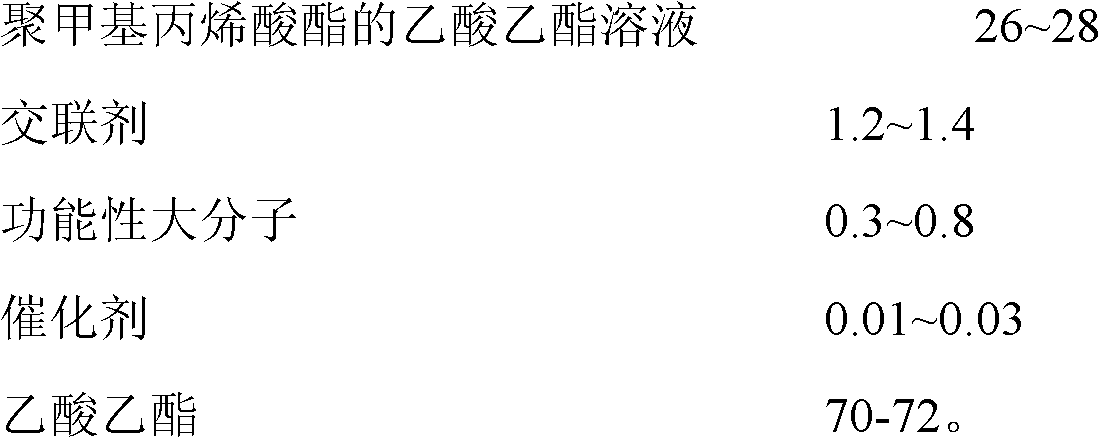

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of ethyl acetate solution of polymethacrylate

[0034] 30.4g butyl acrylate, 79.6g 2-ethylhexyl acrylate, 12.6g dodecyl acrylate, 17.4g ethyl acrylate, 31.6g methyl methacrylate, 3.4g styrene, 105g hydroxyethyl acrylate Esters, 4.48g of benzoyl peroxide were dissolved and mixed evenly for use; 294g of ethyl acetate was added to a 1000ml four-necked reaction flask with a reflux condenser, the temperature was raised to a reflux state, and reflux was maintained, and 25% of the aforementioned mixture was added to the reaction Keep the reaction in the reflux state for 70 minutes in the bottle, and then use the dropping funnel to drop the rest of the aforementioned mixture into the reaction bottle at a constant speed within 180-240 minutes. During the dropping period, the reaction bottle must be kept in a reflux state . After completing the dropwise addition, after continuing the heat preservation and reflux reaction for 70 minutes, add a solution of 63g ethyl...

Embodiment 2

[0044] 1. Preparation of ethyl acetate solution of polymethacrylate

[0045] 30g butyl acrylate, 79.4g 2-ethylhexyl acrylate, 20.2g dodecyl acrylate, 21.6g ethyl acrylate, 110g methyl methacrylate, 65g styrene, 23.8g hydroxyethyl acrylate, 2. Dissolve 24g of benzoyl peroxide and mix evenly for use; add 280g of ethyl acetate into a 1000ml four-necked reaction flask with a reflux condenser, raise the temperature to a reflux state, keep reflux, and add 25% of the aforementioned mixture into the reaction flask , kept in the reflux state for 70 minutes, then used the dropping funnel to add the remaining part of the aforementioned mixture dropwise into the reaction flask at a constant speed within 180-240 minutes, and the reaction flask must be kept in the reflux state during the dropwise addition. After the dropwise addition was completed, continue the insulation reflux reaction for 70 minutes, add a solution of 35g ethyl acetate and 0.28g benzoyl peroxide in the reaction flask, an...

Embodiment 3

[0055] 1. Preparation of ethyl acetate solution of polymethacrylate

[0056] 93.2g butyl acrylate, 158.4g 2-ethylhexyl acrylate, 49.4g dodecyl acrylate, 31.6g methyl methacrylate, 3.4g styrene, 3.5g hydroxyethyl acrylate, 0.28g over Benzoyl oxide is dissolved and mixed evenly for use; 288g of ethyl acetate is added to a 1000ml four-necked reaction flask with a reflux condenser, the temperature is raised to a reflux state, and the reflux is maintained. 25% of the aforementioned mixture is added to the reaction flask and kept at React under reflux for 70 minutes, and then use the dropping funnel to drop the rest of the aforementioned mixture into the reaction flask at a constant speed within 180-240 minutes. During the dropwise addition, the reaction flask must be kept in a reflux state. After the dropwise addition was completed, continue the insulation reflux reaction for 70 minutes, add a solution of 36g ethyl acetate and 0.035g benzoyl peroxide in the reaction flask, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com