Knot tying machine

A technology of knotting machine and casing, applied in the field of knotting machine, can solve the problems of low production efficiency, no mechanization, increased production cost, etc., and achieve the effect of simple and convenient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

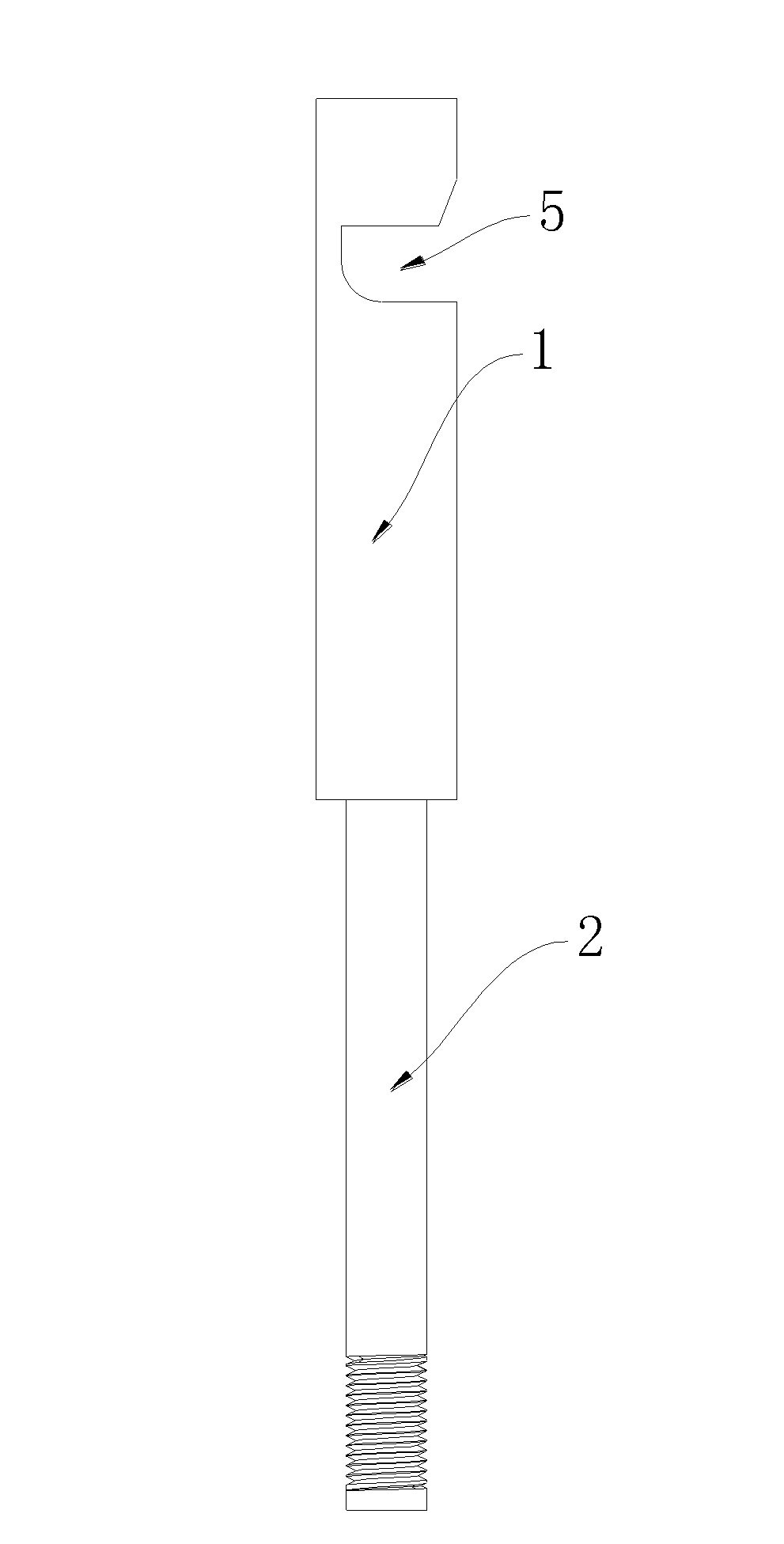

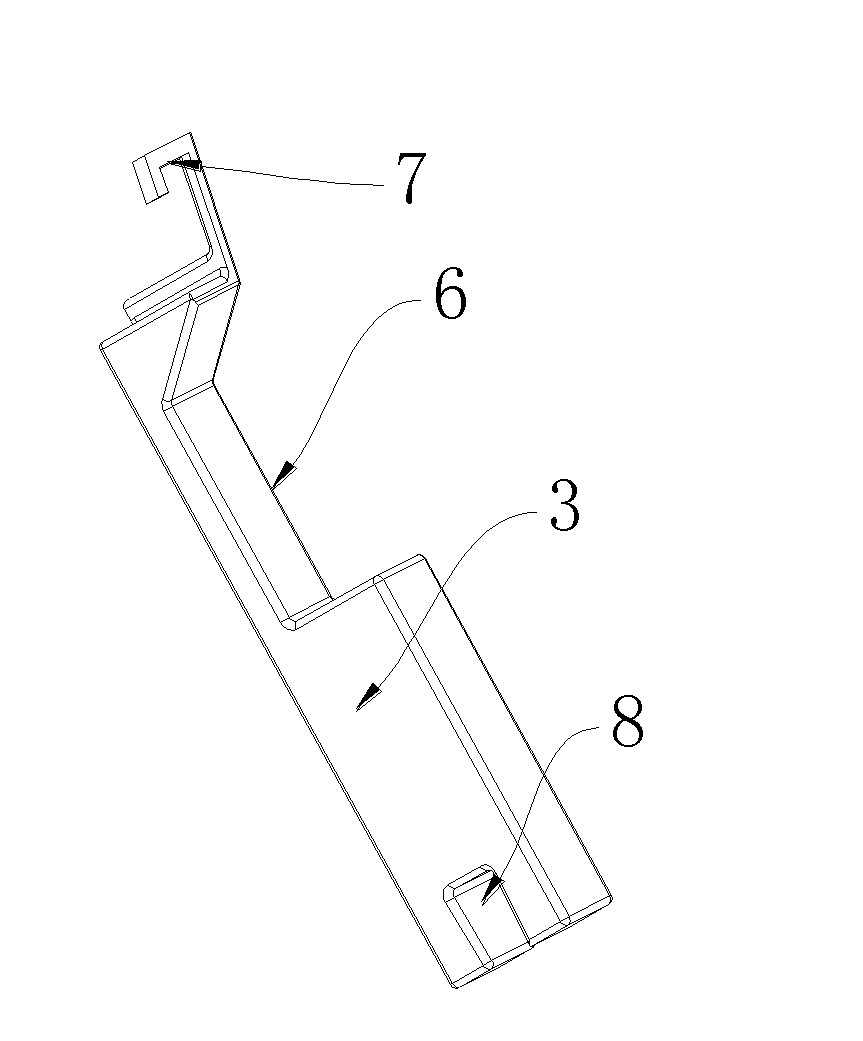

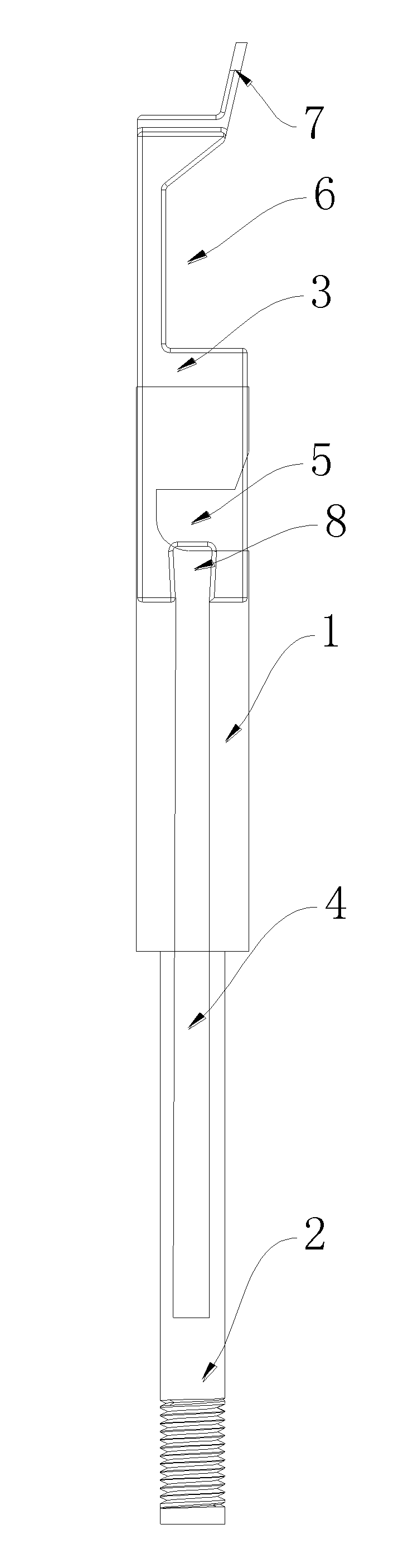

[0012] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the knotting machine described in this embodiment mainly includes a casing 1, which is a flat cuboid shape, hollow, and a connecting pipe 2 is provided at the bottom, and a notch 5 is provided at the upper end of the casing 1, and the notch 5 The side of the upper casing 1 is chamfered, and the machine head 3 is arranged inside the casing 1. The machine head 3 is matched with the casing 1. The upper end of the machine head 3 is provided with a notch on the same side as the notch 5 on the casing 1. 6. The upper side of the notch 6 has an inclined transition, the length of the notch 6 is greater than the length of the notch 5, and a right-angle hook 7 is arranged on the top of the machine head 3, and the right-angle hook 7 is on the same side as the front of the notch 6, and the right-angle hook 7 is set on an outward slope. A bayonet 8 is provided at the bottom of the machine head 3, and the bayonet 8 is conne...

specific Embodiment approach

[0013] Specific implementation method: the head 3 of the knotting machine is inside the casing 1, the notch 5 and the notch 6 are at the same position, and the right-angle hook 7 is outside the casing 1, and the two ends of the rope are clamped and then inserted into the notch 5 Inside, both ends are pulled upwards, the casing 1 drives the machine head 3 to rotate 270° toward the opening of the right-angle hook 7, the right-angle hook 7 hooks one end of the rope, the push rod 4 pulls the machine head 3 to retract into the casing 1, and the notch 5 The rope at the place slides down and moves upwards to realize the knotting of the rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com