Method and device for manufacturing color tufting product

A tufting and product technology, applied in the field of manufacturing color tufted products, can solve the problems of inability to knit products with complex patterns accurately change, inability to knit, position and speed can not keep up, etc., to improve the surface jacquard effect, high work efficiency, clear pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

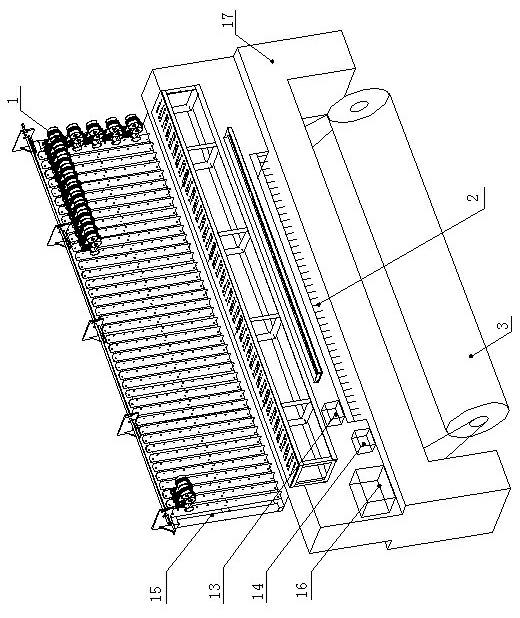

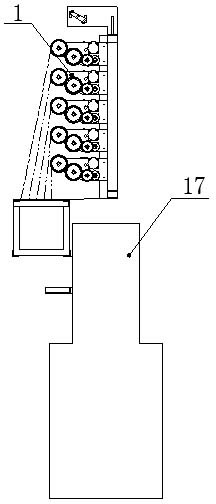

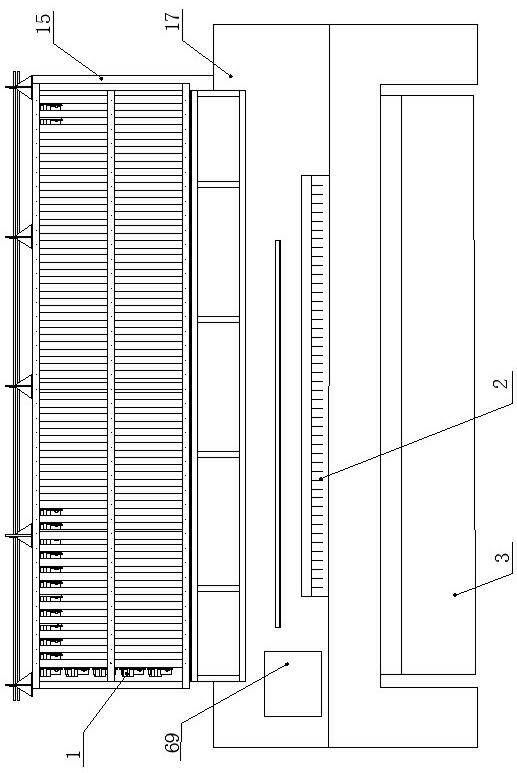

Image

Examples

Embodiment Construction

[0050] A kind of method of making colored tufted product of the present invention, carries out according to the following steps:

[0051] The first step: input the pattern into the computer for non-vectorization processing, and calculate the position and gray value of each pixel; first scan the pattern into the computer, and then perform non-vector calculation to decompose the scanned pattern into several pixels point, and finally form coordinates according to the position of each pixel point; during this process, the color of the pattern scanned into the computer does not change, and different colors are represented by different gray values;

[0052] Step 2: Re-divide lines according to the different gray values of each point; first scan the first line of the original pattern to find out the pixels with the same gray The position on the number of columns, and the remaining positions are the pixels added to the pattern; then find another pixel of gray value, and store it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com