Polishing roller with curved edge openings

A technology of ironing rollers and curved blades, which is applied to textiles, papermaking, and fabric surface trimming. It can solve problems such as unsatisfactory ironing effects and ironing efficiency, and achieve the effect of improving ironing effects and ironing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

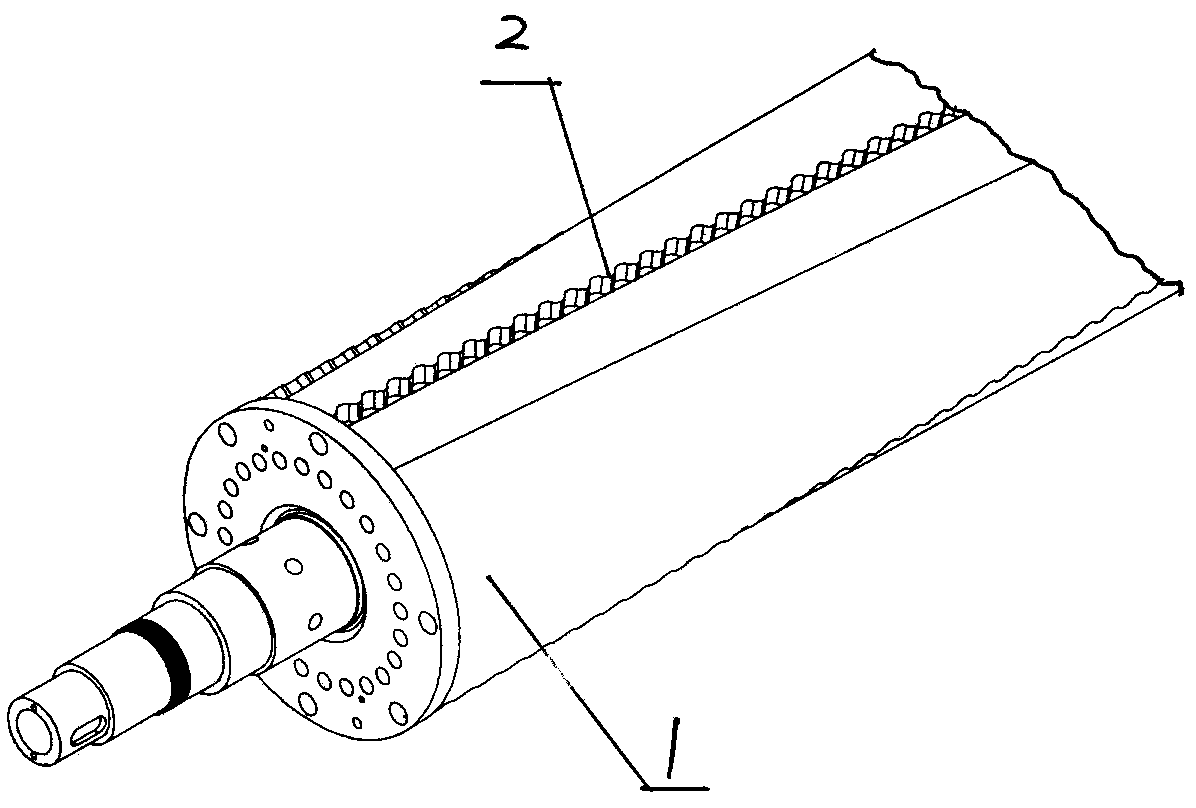

[0008] A curved edge ironing roller, comprising a roll shell 1, several groups of beating grooves are uniformly arranged on the surface of the roll shell 1, each set of beating grooves is composed of two spiral beating blades 2 with opposite rotation directions, the spiral beating blades 2 The cutting edge of the ironing roller is a continuous wavy structure. During the rotation of the ironing roller, the fiber will continuously deflect in three directions: left, middle and right. After multiple beatings of the spiral groove, the roller body polishes the three surfaces of the velvet fiber. . The distance between adjacent crests on the cutting edge is 6-80 mm, the distance from the crest to the trough is 6-15 mm, and the cutting edge is 10-25 mm deep. According to the length of different fabric plush, the size of the wavy cutting edge is adjusted accordingly to obtain a better ironing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com