Synthetic leather scorch powder and preparation method thereof

A synthetic leather scorching powder and micropowder technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of low temperature resistance, good gloss effect, incompatibility between scorching and surface embossing, etc., and achieve high temperature resistance Features, solve technical defects, solve the effect that it is difficult to balance color and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

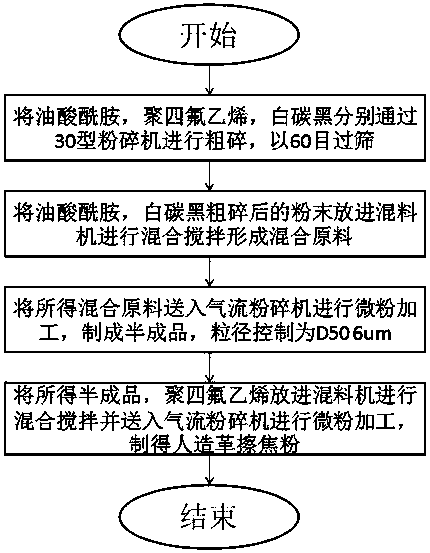

[0026] The oleic acid amide, polytetrafluoroethylene, and white carbon black were respectively coarsely crushed by a 30-type pulverizer, and sieved with a 60-mesh sieve.

[0027] Put oleic acid amide and coarsely crushed white carbon black powder into a mixer at a ratio of 50:20 for mixing and stirring to form a mixed raw material.

[0028] The obtained mixed raw materials are sent to a jet mill for micro-powder processing to make semi-finished products, and the particle size is controlled to be D50=6um.

[0029] The resulting semi-finished product and polytetrafluoroethylene are put into a mixer at a ratio of 70:30 for mixing and stirring, and then sent to a jet mill for micro-powder processing to obtain coke powder for synthetic leather.

[0030] Synthetic leather scorching powder is added with industrial solvent formula to prepare synthetic leather scorching treatment agent.

Embodiment 2

[0032] The oleic acid amide, polytetrafluoroethylene, and white carbon black were respectively coarsely crushed by a 30-type pulverizer, and sieved with a 60-mesh sieve.

[0033] Put oleic acid amide and coarsely crushed white carbon black powder into a mixer at a ratio of 40:20 for mixing and stirring to form a mixed raw material.

[0034] The mixed raw materials obtained are sent to a jet mill for micro-powder processing to make semi-finished products, and the particle size is controlled to be D50=7um.

[0035] The resulting semi-finished product and polytetrafluoroethylene are put into a mixer at a ratio of 60:40 for mixing and stirring, and then sent to a jet mill for micro-powder processing to obtain coke powder for synthetic leather.

[0036] Synthetic leather scorching powder is added with industrial solvent formula to prepare synthetic leather scorching treatment agent.

Embodiment 3

[0038] The oleic acid amide, polytetrafluoroethylene, and white carbon black were respectively coarsely crushed by a 30-type pulverizer, and sieved with a 60-mesh sieve.

[0039] Put oleic acid amide and coarsely crushed white carbon black powder into a mixer in a ratio of 60:20 for mixing and stirring to form a mixed raw material.

[0040] The obtained mixed raw materials are sent to a jet mill for micro-powder processing to make semi-finished products, and the particle size is controlled to be D50=8um.

[0041] Put the obtained semi-finished product and polytetrafluoroethylene into the mixer at a ratio of 80:20 for mixing and stirring, and then send it to the jet mill for micronization processing to obtain coke powder for synthetic leather.

[0042] Synthetic leather scorching powder is added with industrial solvent formula to prepare synthetic leather scorching treatment agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com