Cloth napping process

A cloth and craft technology, applied in the field of gray cloth processing, can solve problems such as the decline in the quality of ironing, and achieve the effects of not being easy to rotate, improving applicability, and improving the effect of ironing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

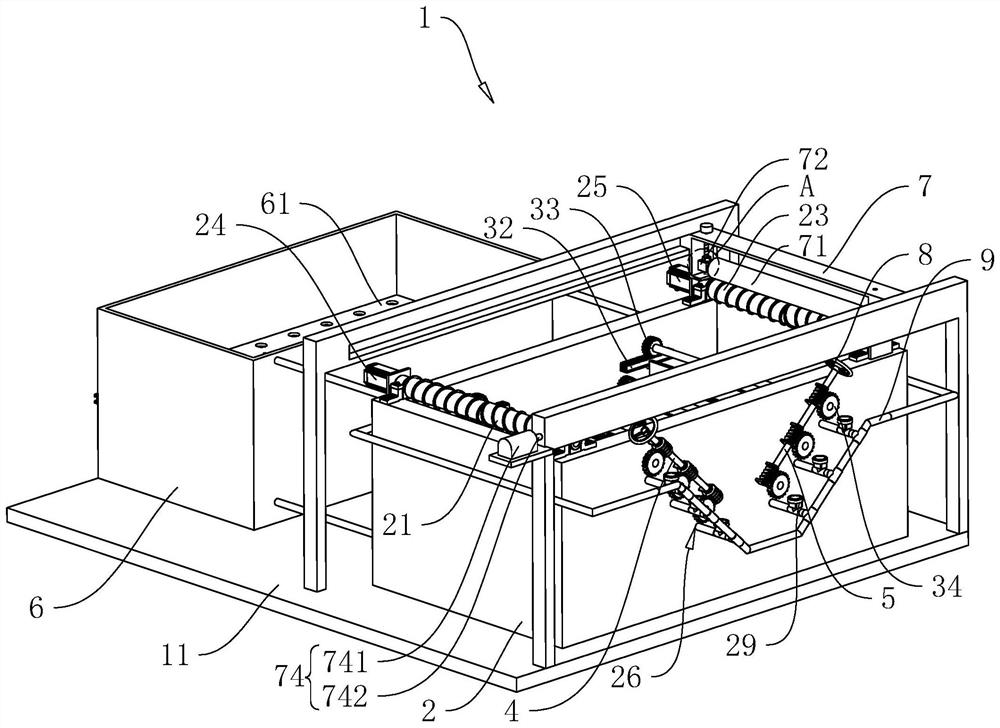

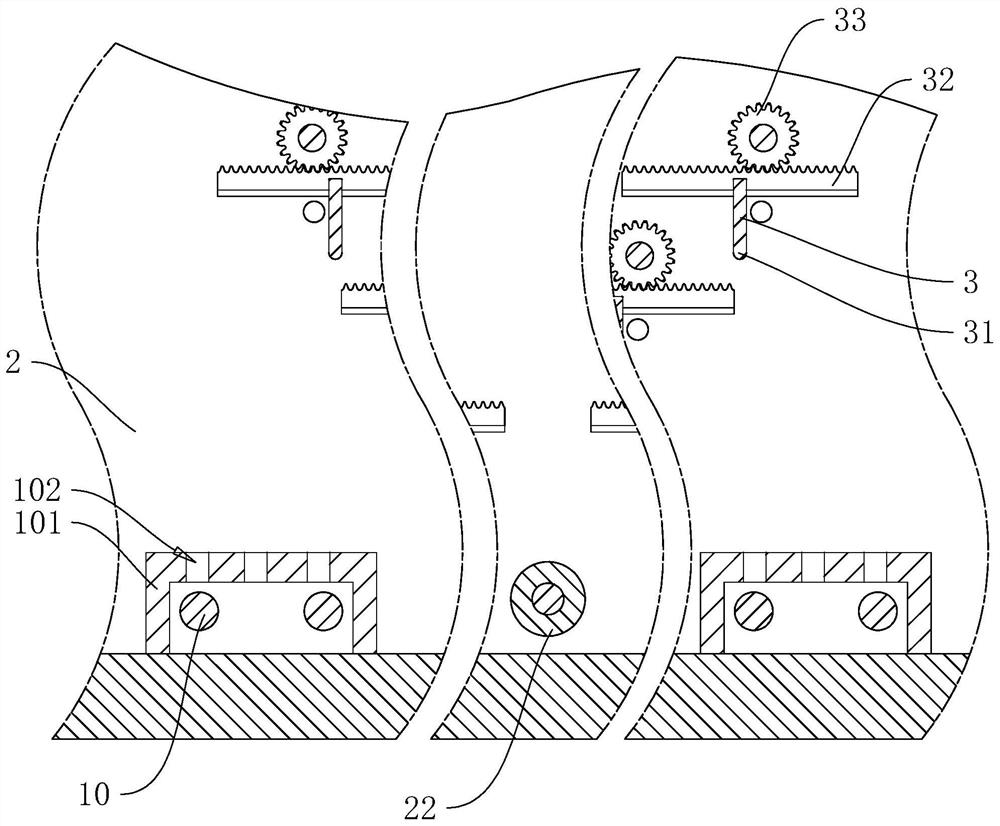

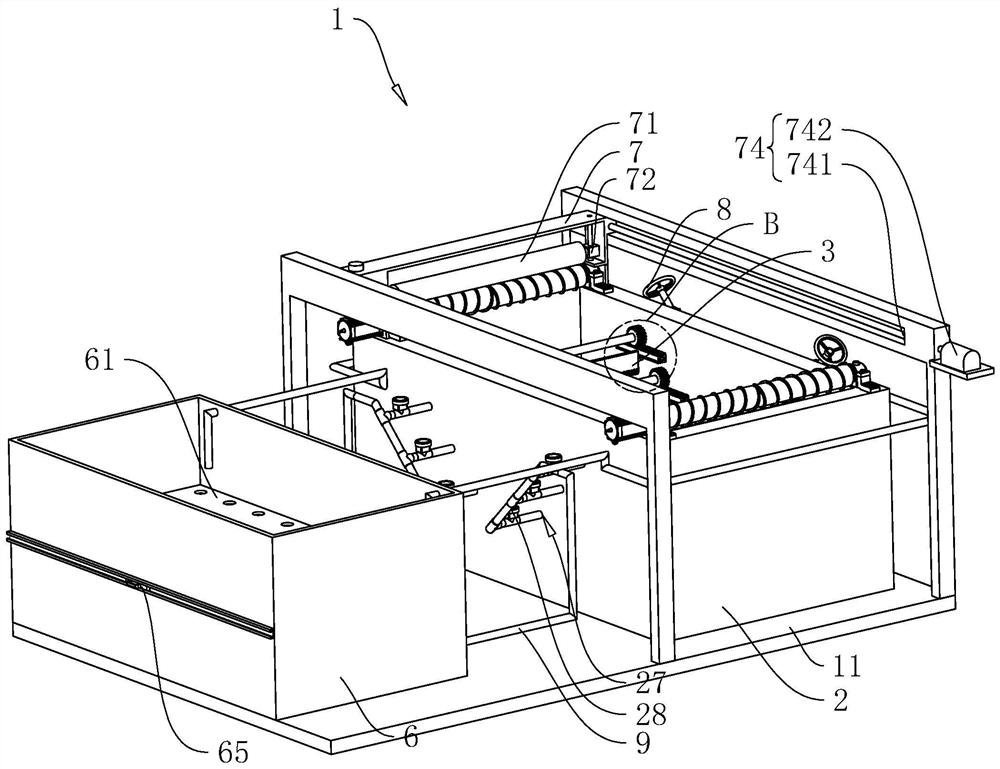

[0045] The following is attached Figure 1-6 The application is described in further detail.

[0046] The embodiment of the present application discloses a cloth napping process, which includes the following steps:

[0047] S1: Fabric preparation;

[0048] S2: Raising the gray cloth surface;

[0049] S3: shearing the plush on the gray cloth by a shearing machine;

[0050] S4: Ironing the outer surface of the gray cloth with an ironing machine;

[0051] S5: Carry out shake grain treatment on the plush of the gray cloth;

[0052] S6: After the gray cloth is cleaned at the setting machine, the tenter setting is carried out on the setting machine, and the production of the fabric is completed.

[0053] refer to figure 1 In S3, the sheared fabric is washed by the washing device 1, and then in S4, the washed fabric is sent to the ironing machine for drying and ironing.

[0054] refer to figure 1 and figure 2 The washing device 1 includes a frame 11 connected to the shearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com