Ironing roller with temperature compensation capacity

A temperature compensation, ironing roller technology, used in textiles and papermaking, fabric surface trimming, etc., can solve the problems of rapid heat loss, inability to detect temperature, and inability to quickly compensate, so as to ensure the effect of ironing and ironing. Perfect, extended service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

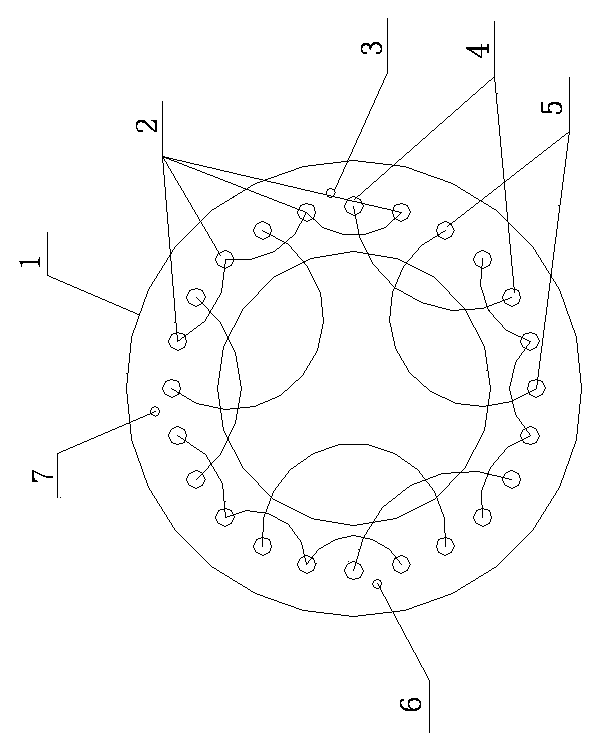

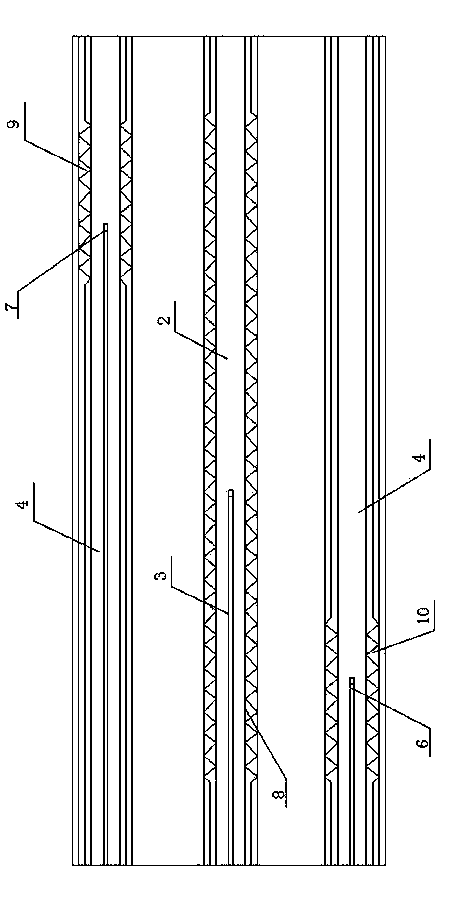

[0014] Refer to attached figure 1 and figure 2 , a kind of ironing roller capable of temperature compensation, 12 main heating pipes 2 are evenly distributed along its circumferential direction in the ironing roller 1, and each adjacent four are connected in series to form a group, forming three groups in total, each The groups are respectively connected to one phase of the three-phase power supply; an auxiliary heating tube at the end is provided between each two adjacent main heating tubes 2, and the auxiliary heating tube at the end is on the same circumferential surface as the main heating tube 2, The end auxiliary heating tubes include 6 front auxiliary heating tubes 4 and 6 rear auxiliary heating tubes 5, the front auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com