Automatic compensation clutch and realizing method for automatic compensation clutch

An automatic compensation and clutch technology, applied in the direction of mechanical drive clutches, clutches, friction clutches, etc., can solve the problems of complex structure, reduce the reliability of the actuator, and difficult to control, and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

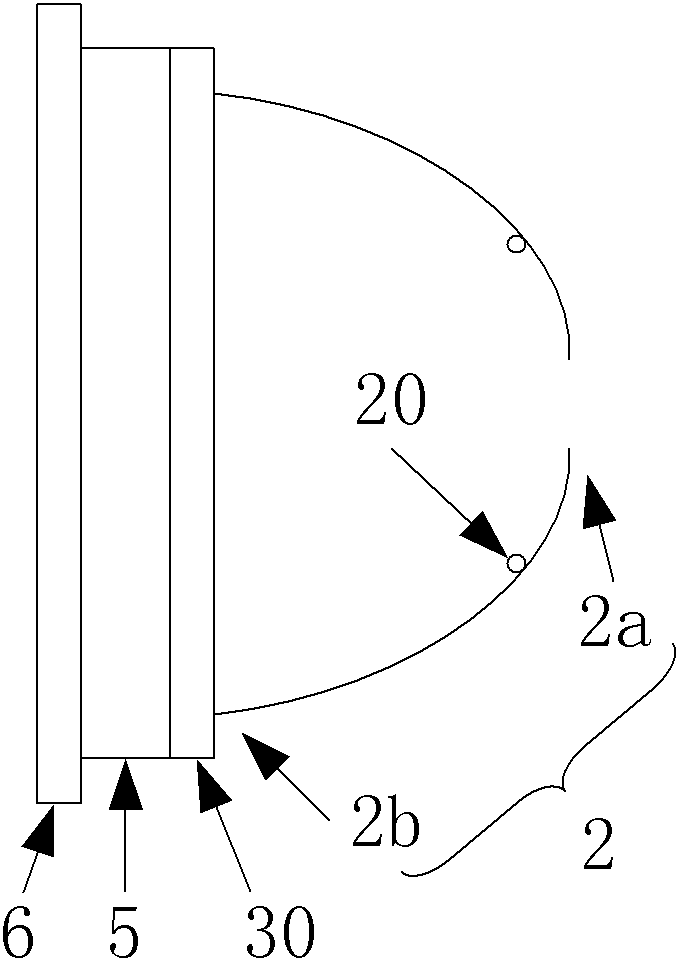

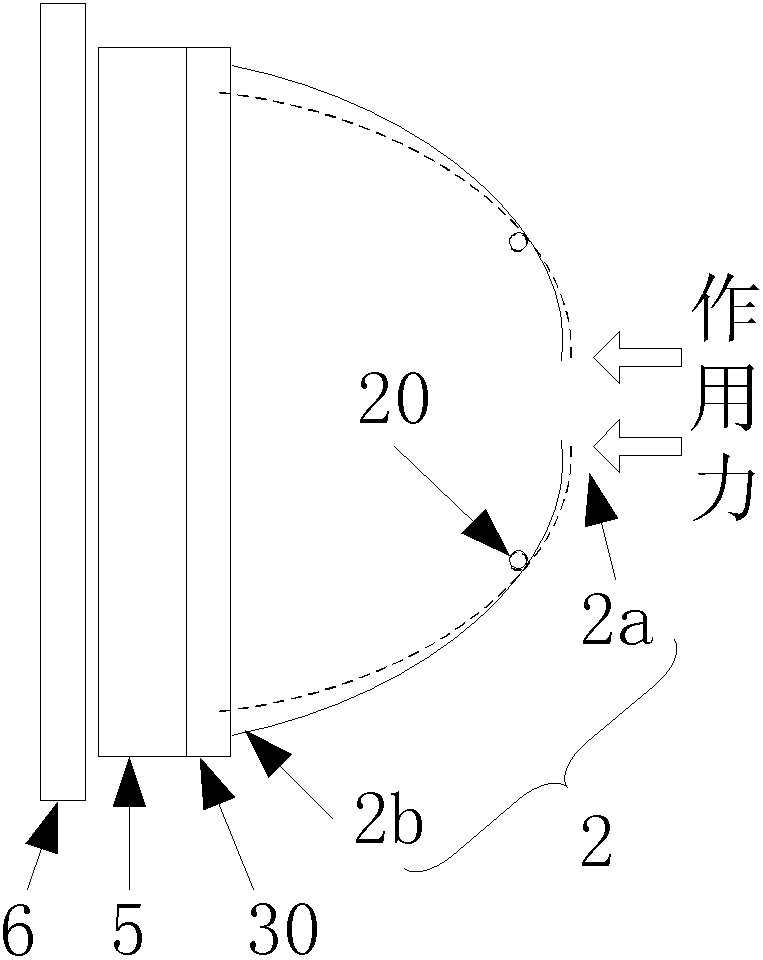

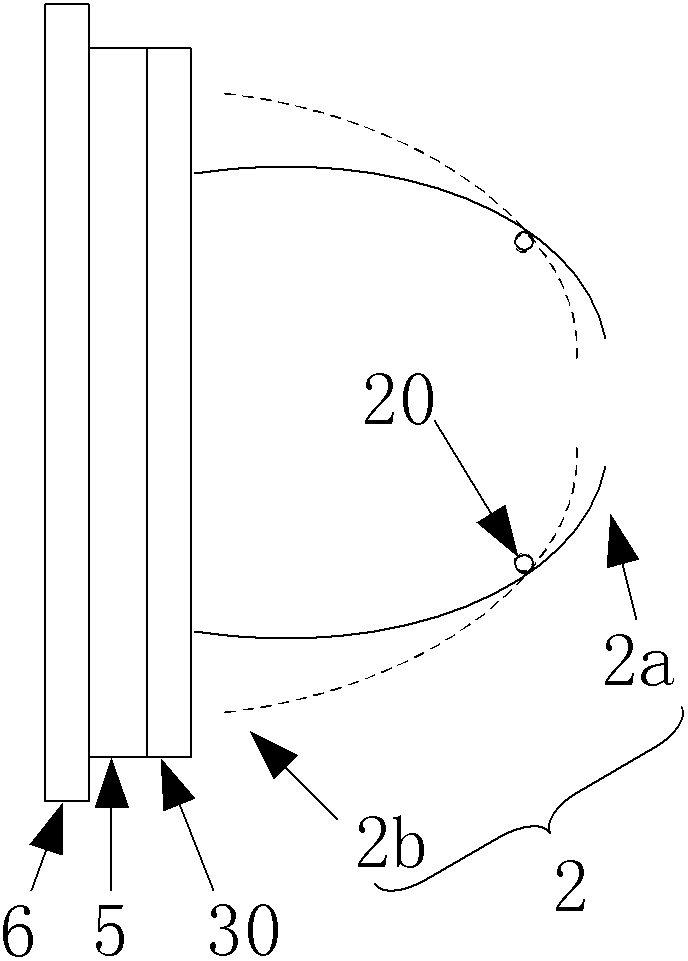

[0045] see image 3 , the automatic compensating clutch of the present invention comprises:

[0046] ——The housing 1 is in the shape of an inverted bowl and is fixed on the flywheel 6 , forming a first cavity between the housing 1 and the flywheel 6 . On the upper side 11 of the housing 1 there is a hole 111 .

[0047] - The diaphragm spring 2 is disc-shaped and located in the first cavity. The pressure-receiving end 2a of the diaphragm spring 2 protrudes out of the hole 111 on the top surface of the casing, and is used for contacting with the release bearing. The middle part of the diaphragm spring 2 is fixed on the housing 1 . The other end 2b of the diaphragm spring 2 is connected to the auxiliary pressure plate 3 . The diaphragm spring 2 is equivalent to a lever, and when its pressure receiving end 2a is pressed down, its other end 2b will be lifted toward the top surface 11 of the housing.

[0048] - The auxiliary pressure plate 3 is in the shape of an inverted cylin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap