Optimisation of actuating an automated transmission, in particular an automated transmission of a commercial vehicle

A technology of automatic gearboxes and gearboxes, which is applied in the direction of engine testing, transmission control, and components with teeth, etc., to achieve the effect of saving high costs and simplifying applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The synergy of drive motor and automatic gearbox is known from eg DE 19802736A1.

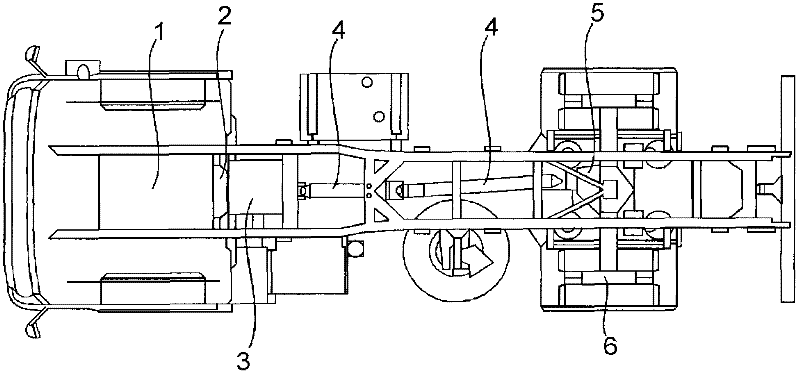

[0038] in addition, figure 1 The drawing shows a commercial vehicle as a whole, comprising an engine 1 , a clutch 2 , an automatic transmission 3 , a cardan shaft 4 , a main drive 5 and a hub drive 6 as drive train components.

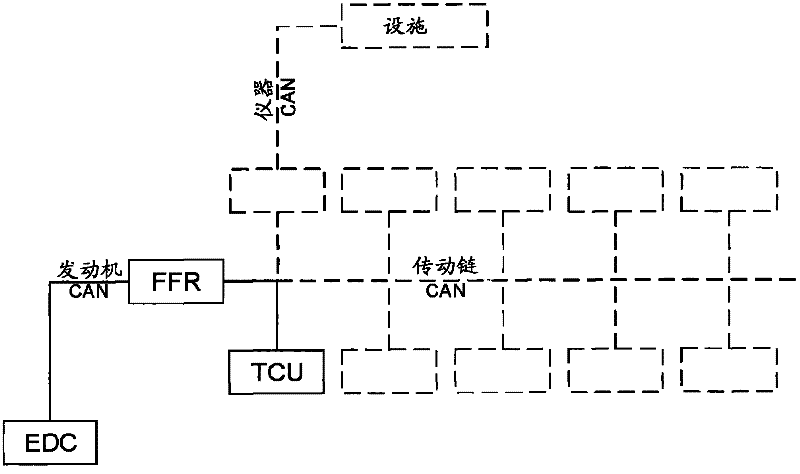

[0039] In this case, a controller EDC is arranged in the engine 1 and a controller TCU is arranged in the transmission 3 including the clutch 2 . A vehicle control computer FFR placed in between is connected with the controller EDC and the controller TCU through the network CAN, such as figure 2 shown. other in figure 2 The inserted, unnamed blocks shown in dotted lines describe examples of other equipment of the commercial vehicle, but these are not relevant for further explanation of the invention.

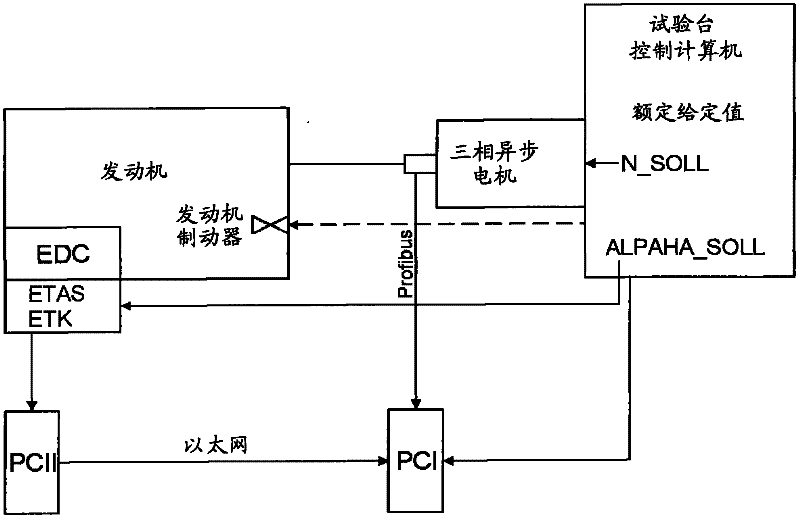

[0040] The data exchange between the control unit EDC and the control unit TCU takes place via a large number of data and / or signals that have been establishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com