Self-adaptive failure diagnosis method of rotary mechanical component based on continuous wavelet transformation

A technology of rotating machinery and wavelet transformation, which is applied in the direction of mechanical bearing testing, machine gear/transmission mechanism testing, etc., can solve the problem that the center frequency of the band-pass filter is difficult to determine, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

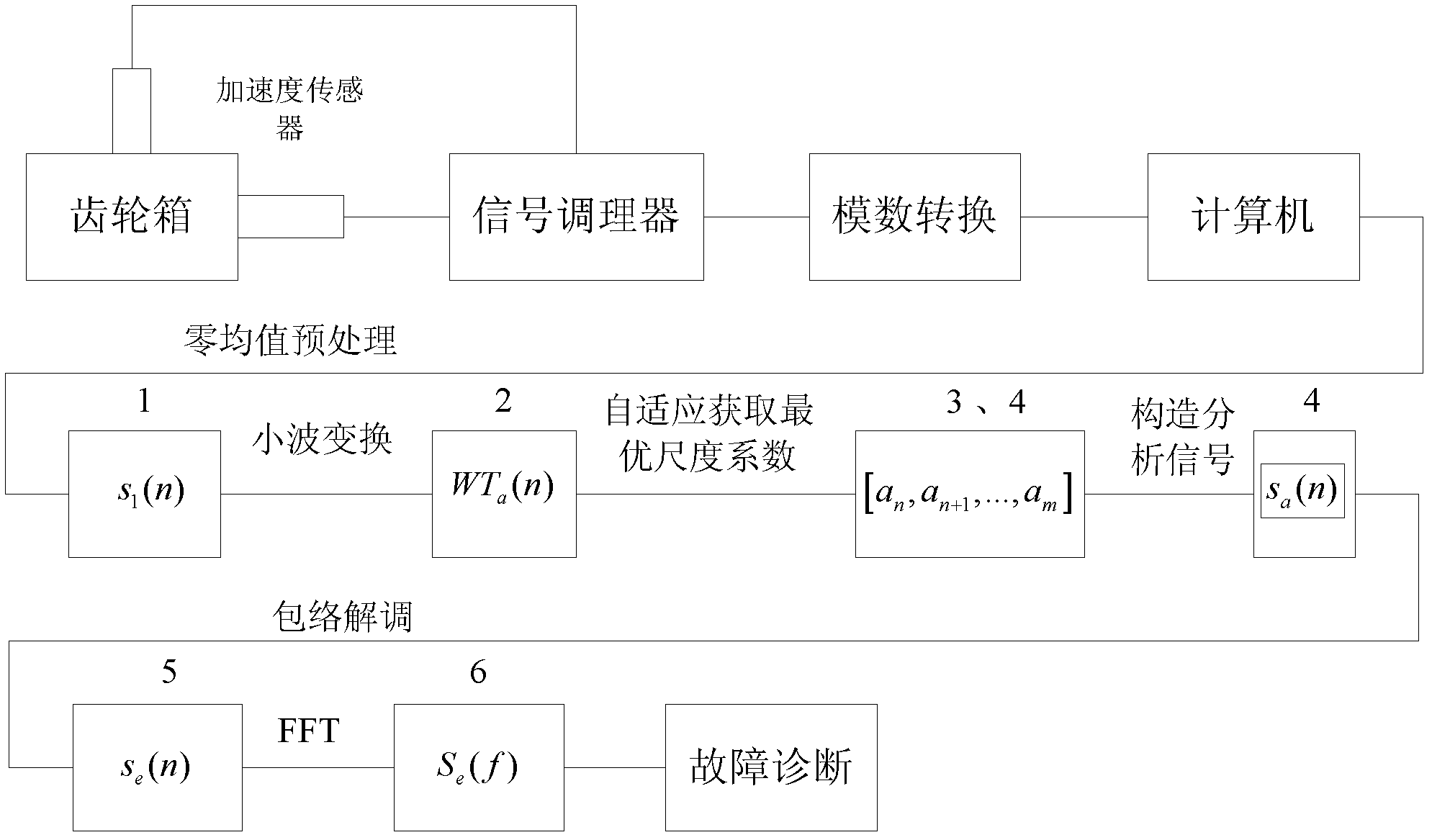

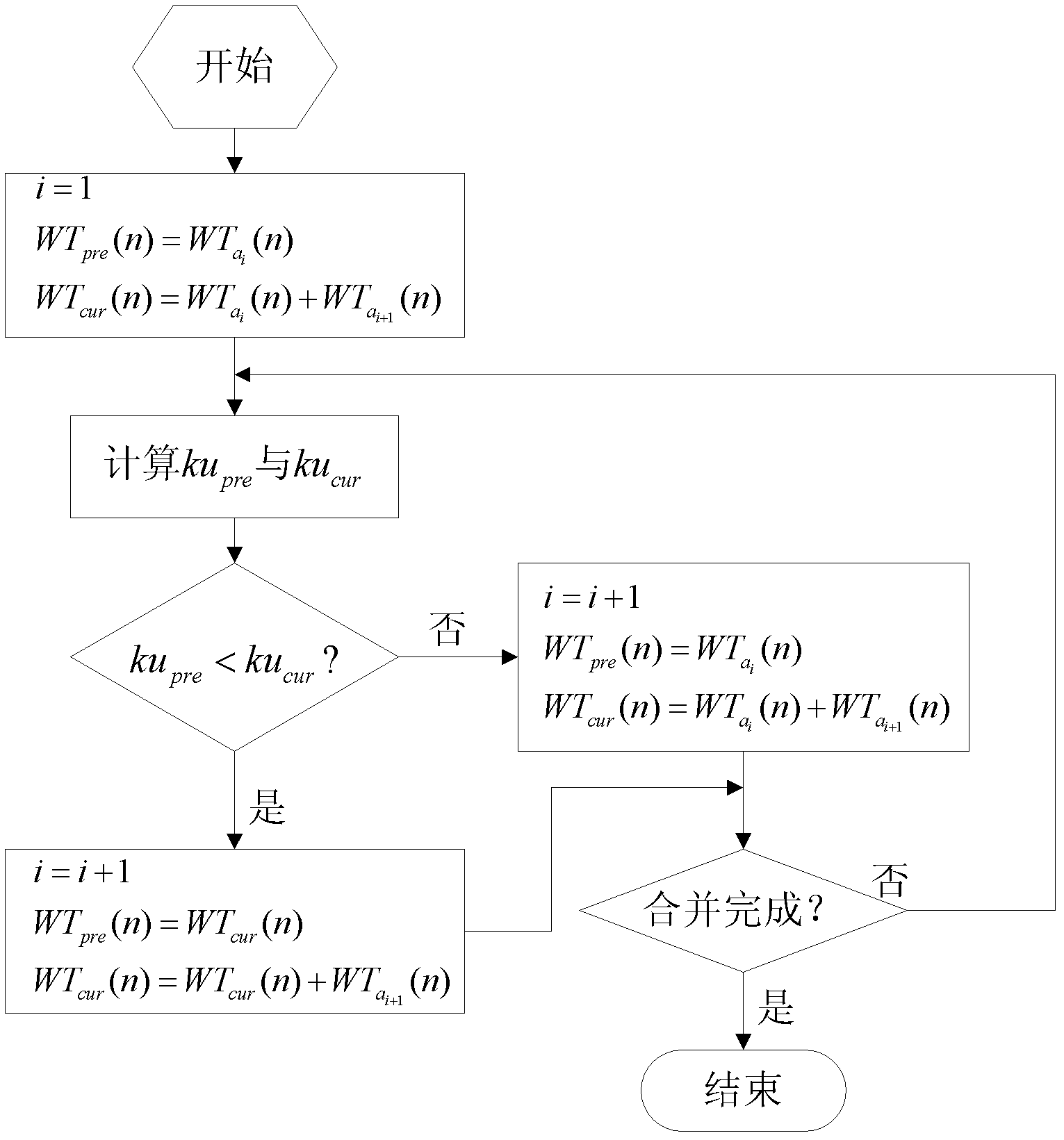

[0024] Such as figure 1 As shown, the adaptive fault diagnosis method of rotating machinery parts based on continuous wavelet transform, such as figure 1 As shown, the steps include:

[0025] Step 1: Perform zero-mean preprocessing on the obtained discrete initial vibration signal s(n) to obtain a preprocessed signal s that eliminates the DC component 1 (n).

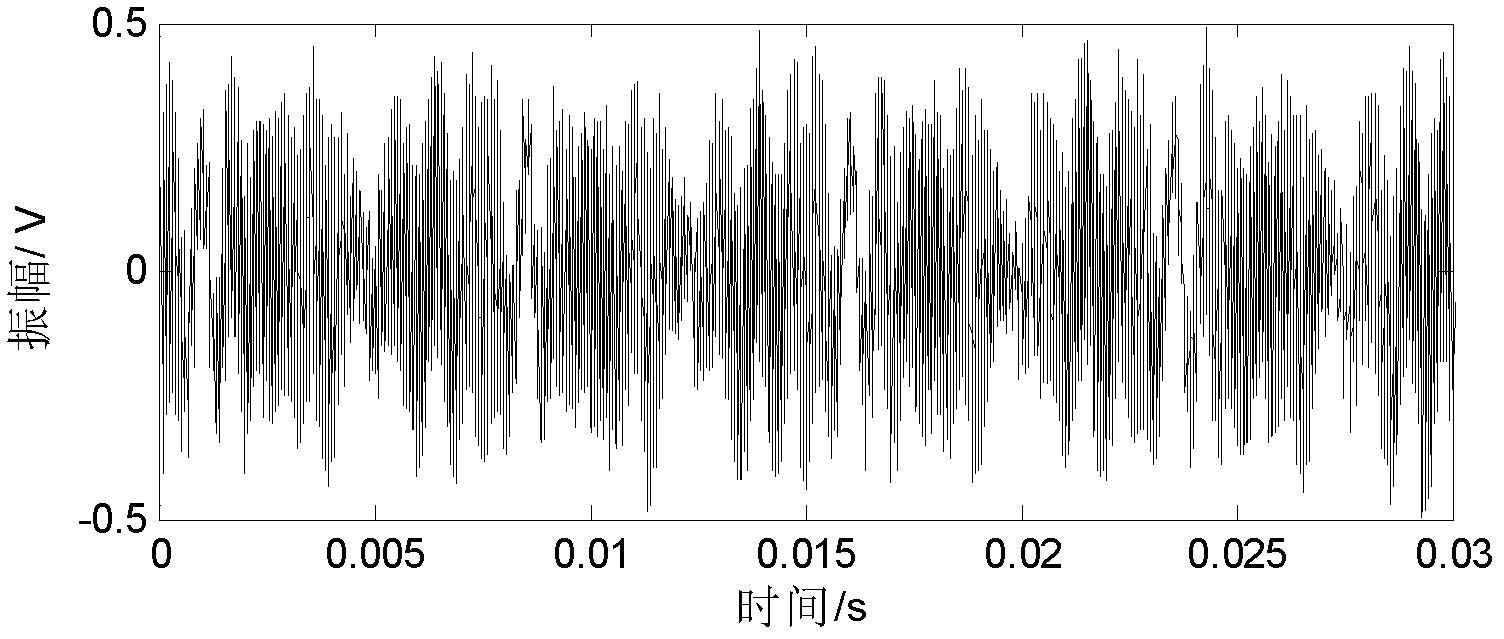

[0026] In this embodiment, the gear box is used as the object of fault diagnosis. The vibration signal of the gear box is collected by an acceleration sensor, and the collected vibration signal is obtained by using a signal conditioner and analog-to-digital conversion to obtain a discrete initial vibration signal s(n), and Send the signal to the computer for zero-mean preprocessing. The zero-mean preprocessing is to eliminate the influence of the DC component in the initial vibration signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com