Method for measuring surface structure of display device

A display device and surface structure technology, applied in the field of display device surface structure and measuring its surface structure size, display device and measuring its surface structure, can solve the problem of product yield decline, accuracy and reproducibility of structure size measurement results Poor, unable to obtain uniform reflected light and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

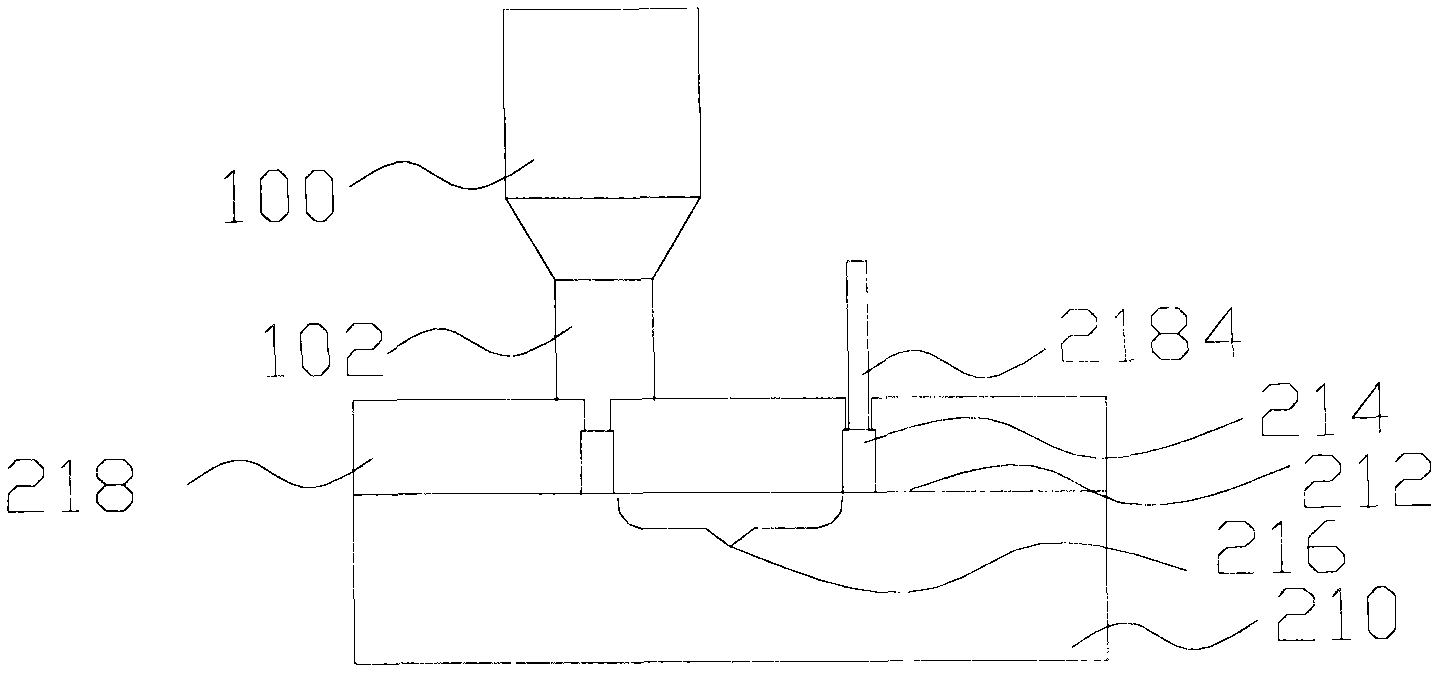

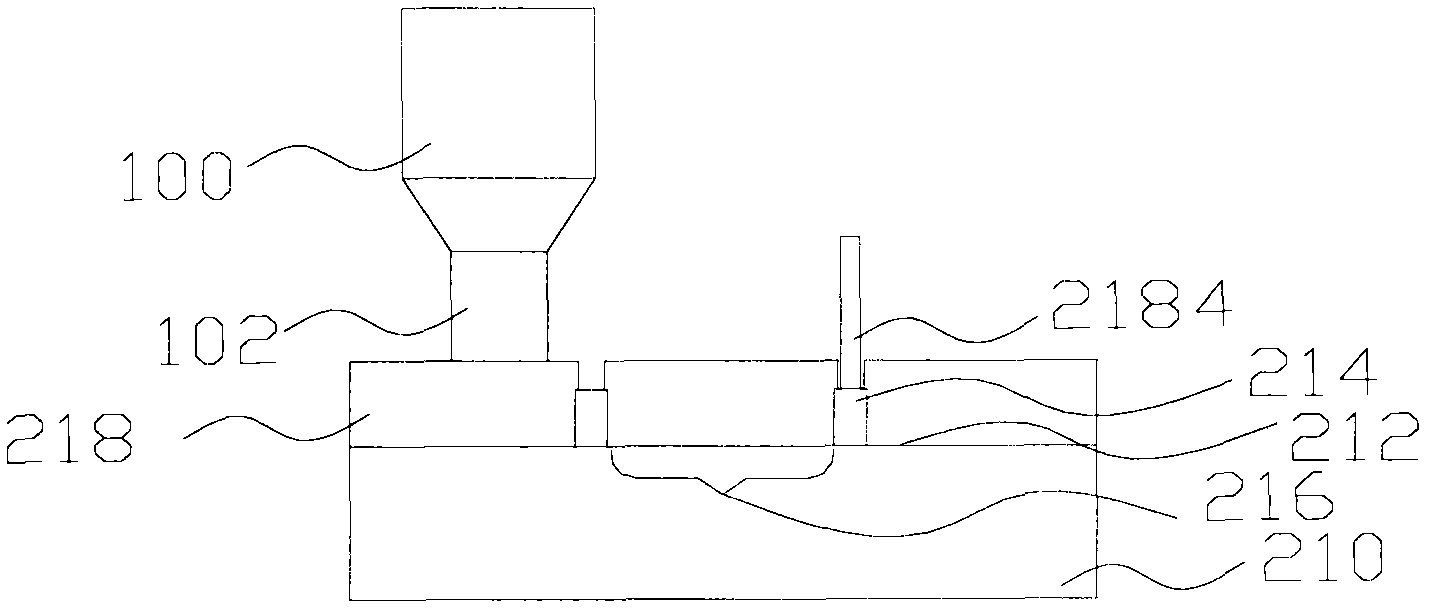

[0022] See Figure 5 , A display device 300 of an embodiment of the invention, such as a liquid crystal display, includes: a first substrate 310 having a first surface 312;

[0023] A first patterned light-shielding layer 322, including a plurality of first openings 324, disposed on the first surface 312 of the first substrate 310;

[0024] At least one second patterned light-shielding layer 332, including a plurality of second openings 334, disposed between the first patterned light-shielding layers 322 on the first surface 312 of the first substrate 310;

[0025] The at least one first pixel unit 326 includes:

[0026] At least one first red filter layer 326R, at least one first blue filter layer 326B, and at least one first green filter layer 326G respectively cover the first openings 324 of the first patterned light-shielding layer 322 And a part of the first patterned shading layer 322;

[0027] At least one columnar spacer 328 is disposed in the first patterned light-shielding la...

Embodiment 2

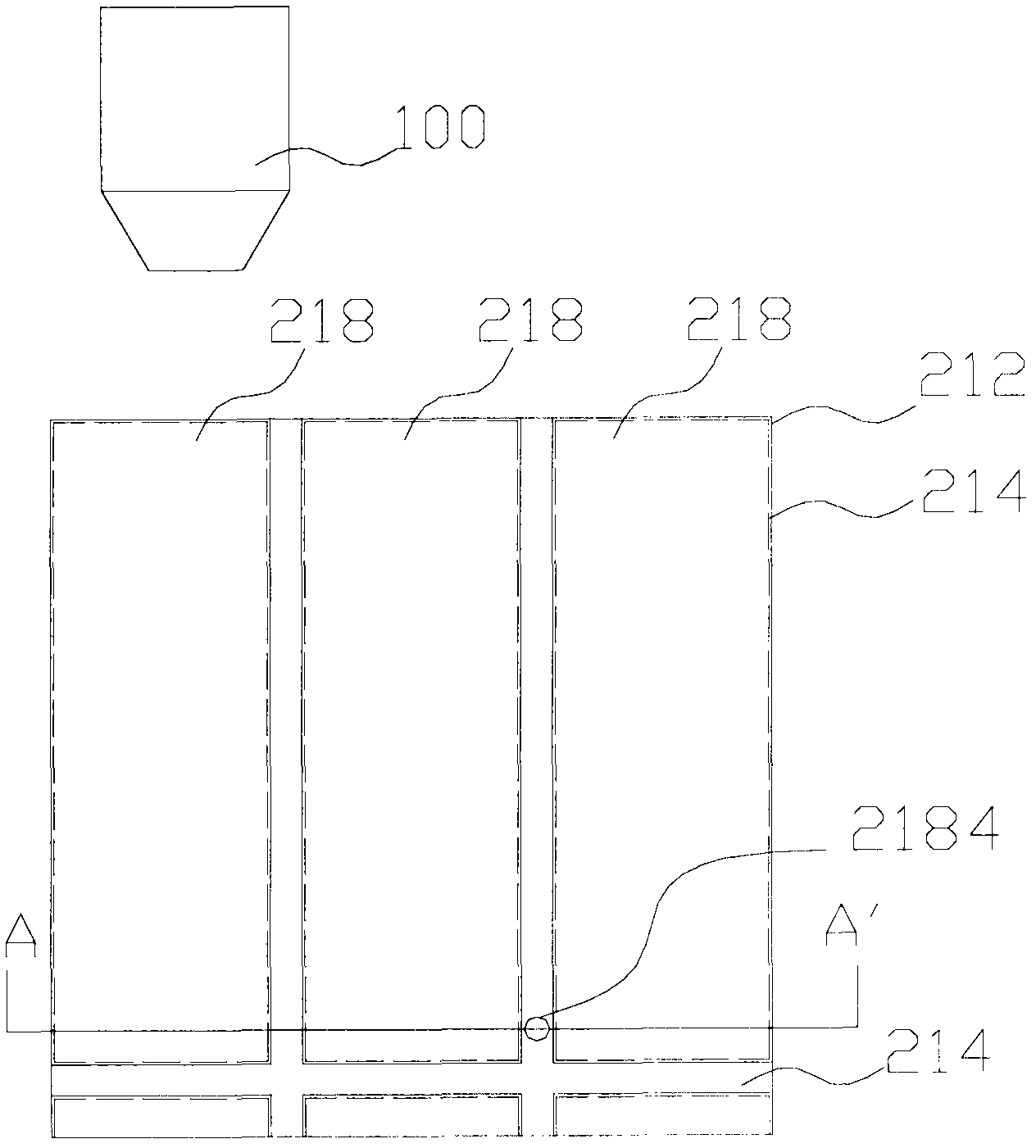

[0034] See Figure 5 versus Image 6 , Image 6 for Figure 5 A plan view of the first substrate 310 of the second embodiment of the present invention, the method for measuring the surface structure of a display device includes:

[0035] Providing a display device 300, such as a liquid crystal display, including: a first substrate 310 having a first surface 312;

[0036] A first patterned shading 322, including a plurality of first openings 324, disposed on the first surface 312 of the first substrate 310;

[0037] At least one second patterned light-shielding layer 332, including a plurality of second openings 334, disposed between the first patterned light-shielding layers 322 on the first surface 312 of the first substrate 310;

[0038] The at least one first pixel unit 326 includes:

[0039] At least one first red filter layer 326R, at least one first blue filter layer 326B, and at least one first green filter layer 326G respectively cover the first openings 324 of the first pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com