LED bulb

A technology of LED light bulbs and LED circuit boards, which is applied to the cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., and can solve the problems of shortened service life of HPLEDs, no waterproof, and ineffective sealing of copper heads and other issues to achieve the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

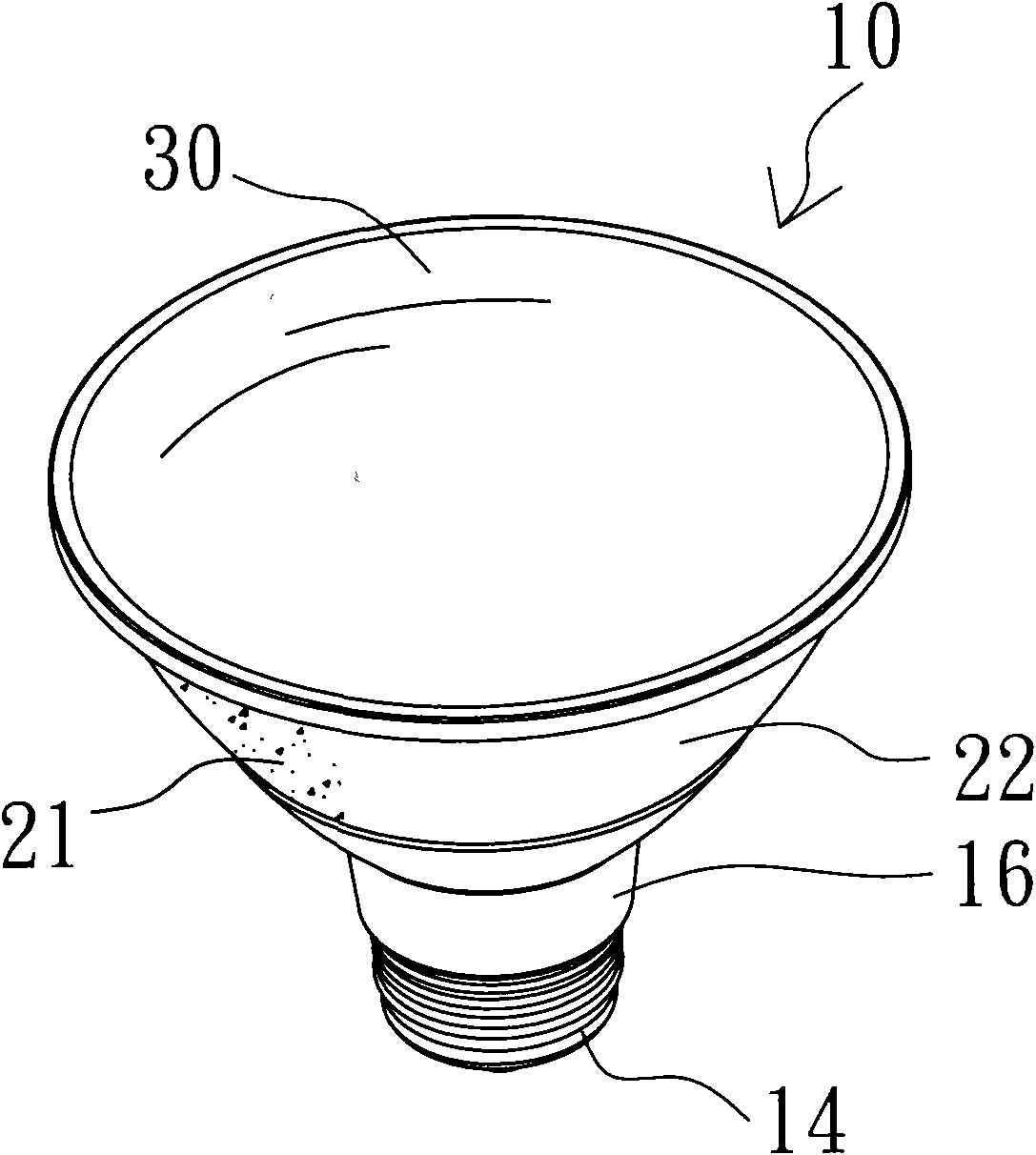

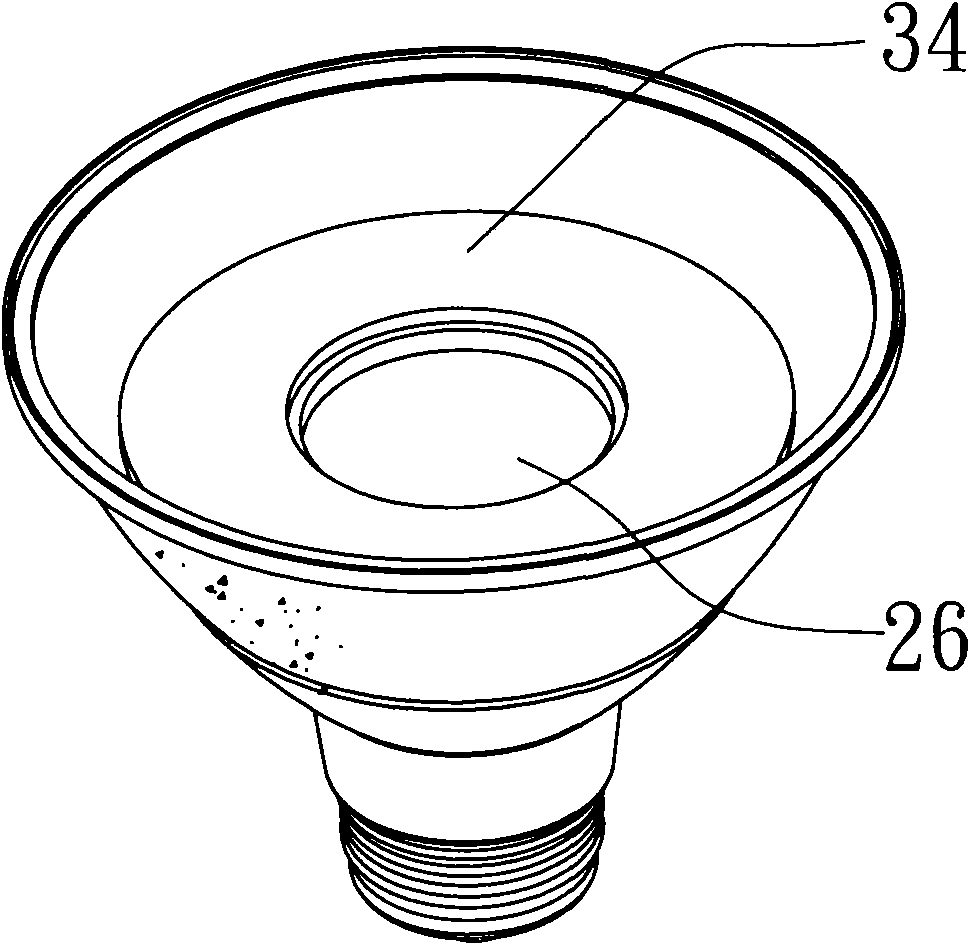

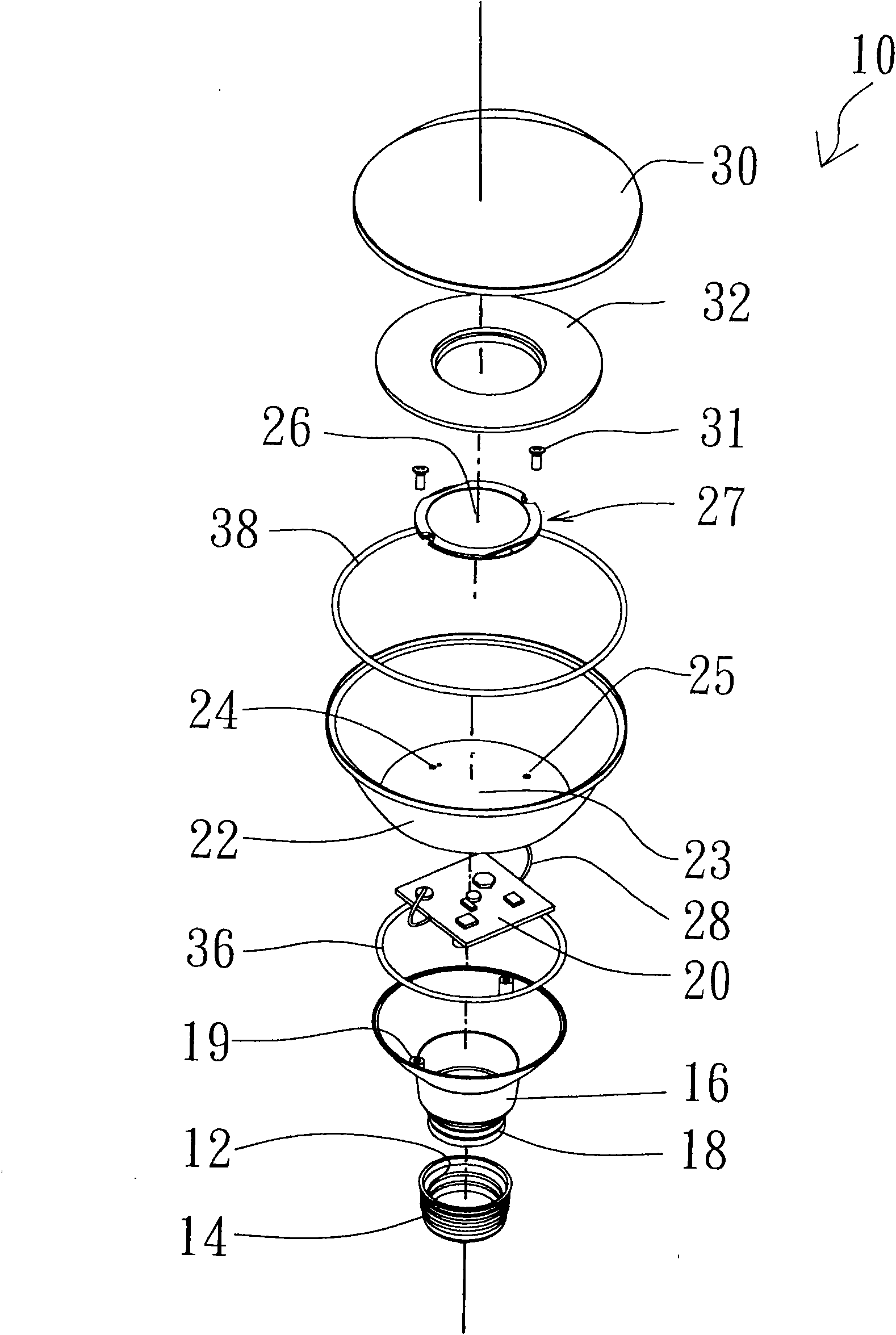

[0030] Please also refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , each of which is a perspective view of the LED light bulb of the present invention, a perspective view after removing the convex lens, an exploded view of components viewed from a top view, an exploded view of components viewed from a bottom view, and a cross-sectional view.

[0031] As shown in the figure, the LED light bulb 10 of the present invention includes a lamp cap 14 with a first thread 12 formed on the inner periphery and made of copper; an insulating tube 16 with a second thread corresponding to the first thread 12 formed around its bottom end 18, to screw-lock the insulating tube 16 on the lamp cap 14, two locking holes 19 are formed on the top of the insulating tube 16; a driver circuit board assembly 20 installed in the insulating tube 16 and electrically connected to the lamp cap 14 at one end; The heat dissipation cup 22 arranged on the top of the insulating tube 16, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com