Riveting device

A riveting device and screwing technology, which is applied in the field of riveting devices, can solve the problem that hexagon socket head cap screws cannot be used, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

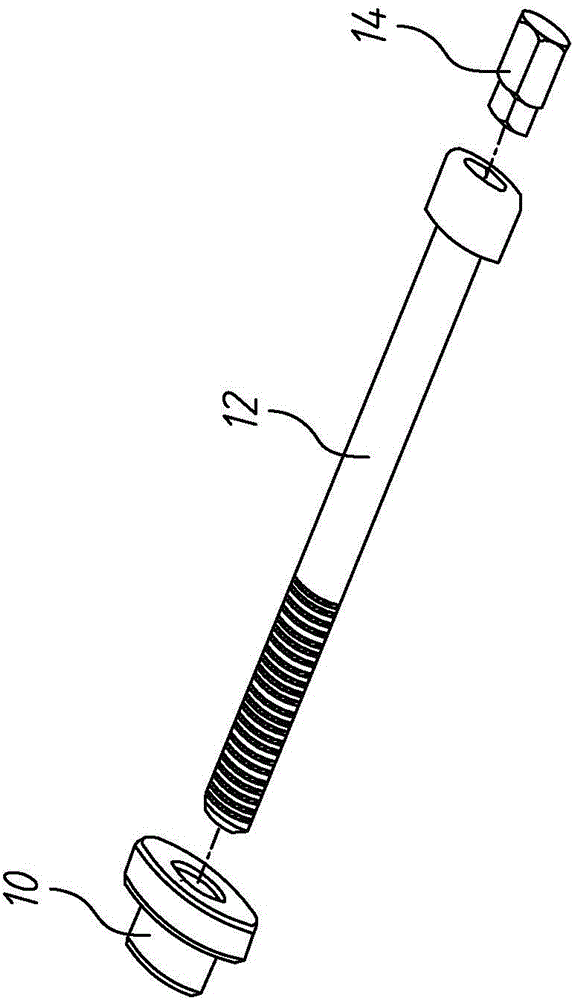

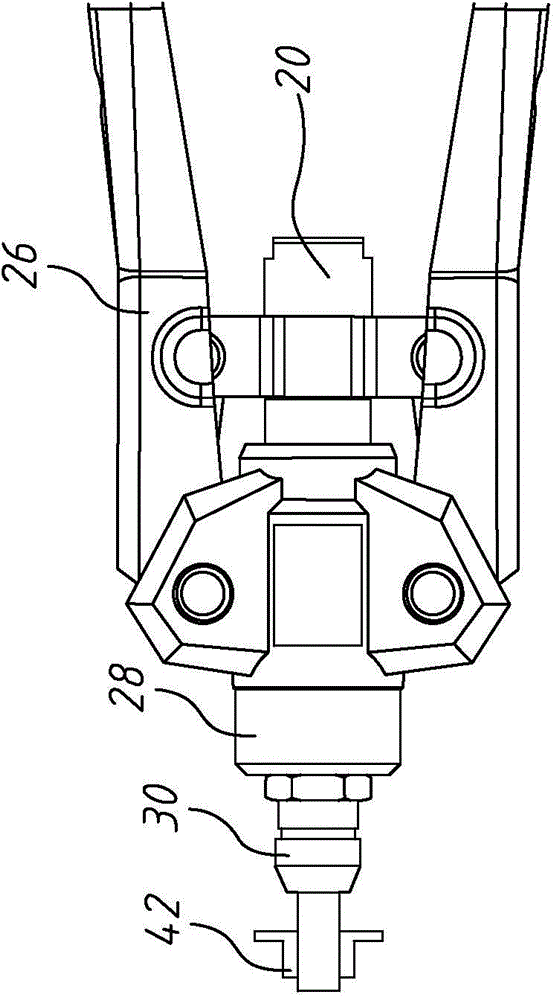

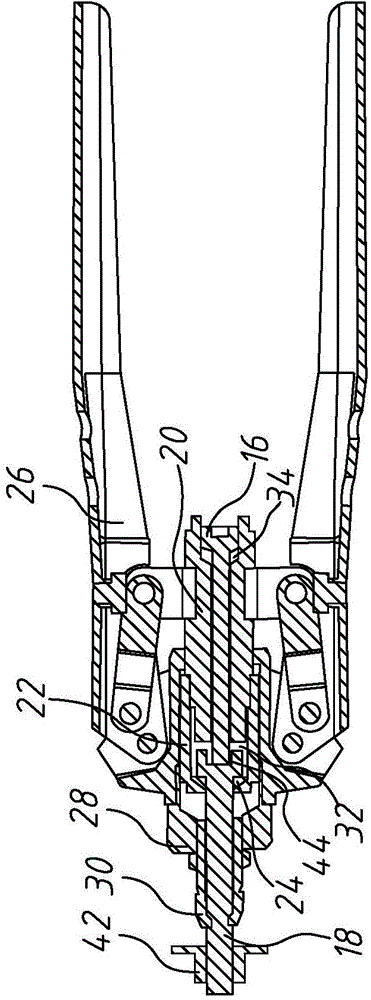

[0035] see figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , The riveting device of the present invention comprises a push rod 16, a screw 18, an inner guide sleeve 20, an outer guide sleeve 22, a buckle 24, a driver 26, an outer protective tube 28 and an inner protective tube 30, Wherein the push rod 16 is a metal push rod, the screw 18 is a metal screw, as a dental rod (MANDREL), the shape of the screw 18 is not limited, the inner guide sleeve 20 is a metal inner guide sleeve, and the outer guide sleeve 22 is a metal outer guide sleeve. Guide sleeve, buckle 24 is a metal buckle. Here, the driver 26 is an example of a manual driver, such as a manual handle, and is combined and fixed with the inner guide sleeve 20 . The inner guide sleeve 20 has a first space 32 and a second space 34 communicating with each other, and the first space 32 surrounds part of the second space 34 . The side wall of the head of the push rod 16 has a first thread, the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com