Tooth implantation guide tool set and tooth implantation guide sleeve thereof

A technology of guiding tools and guiding sleeves, which is applied in the field of dental implant tool sets and components, which can solve the problems of increased tool manufacturing costs, increased working distance, and increased working space required for dental implants, so as to ensure the effect of lubrication and cooling, The effect of stable and safe use and shortened application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

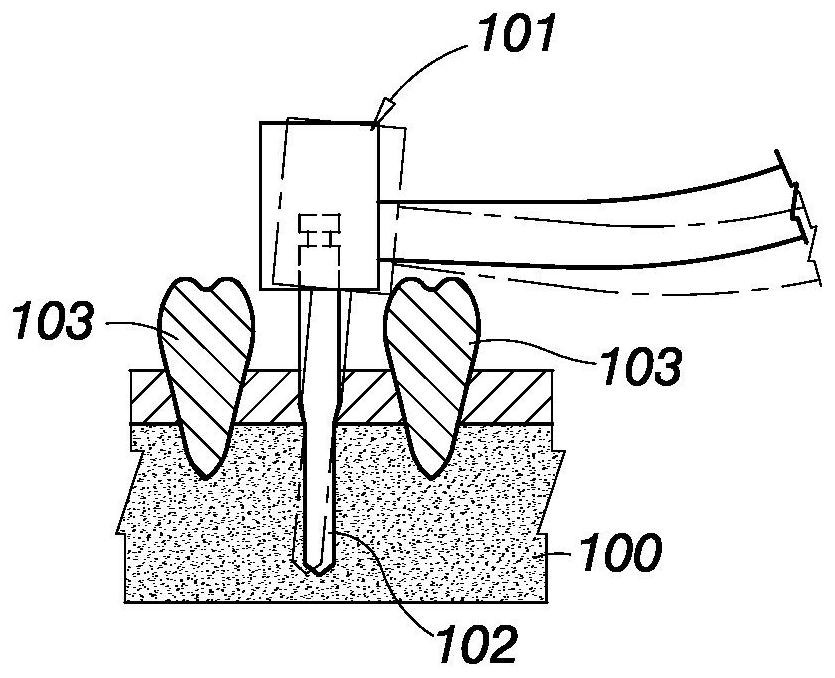

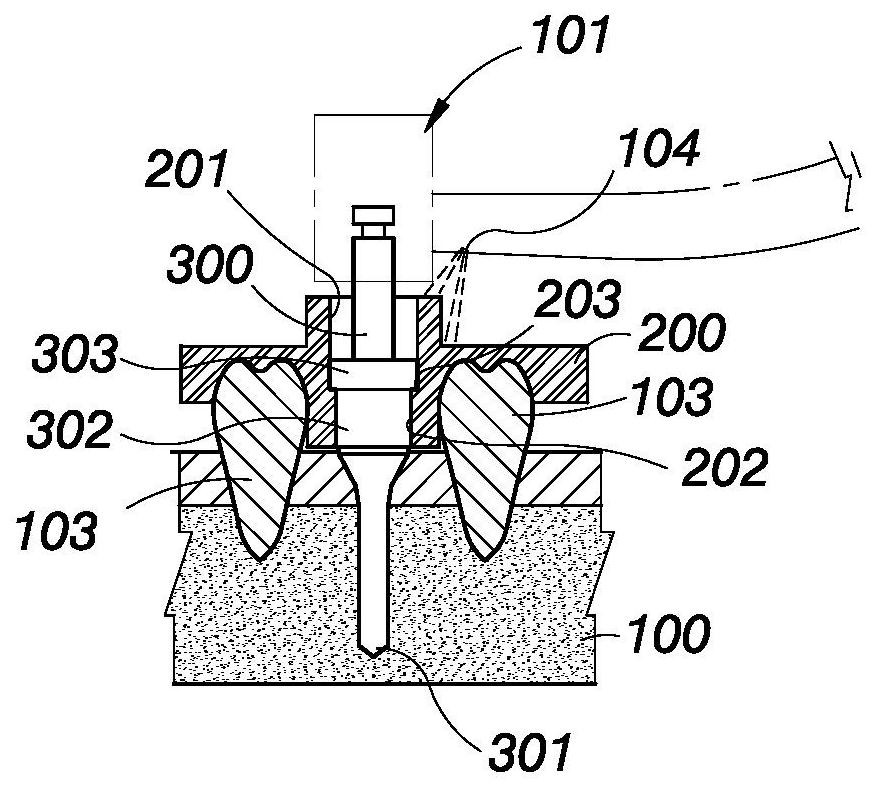

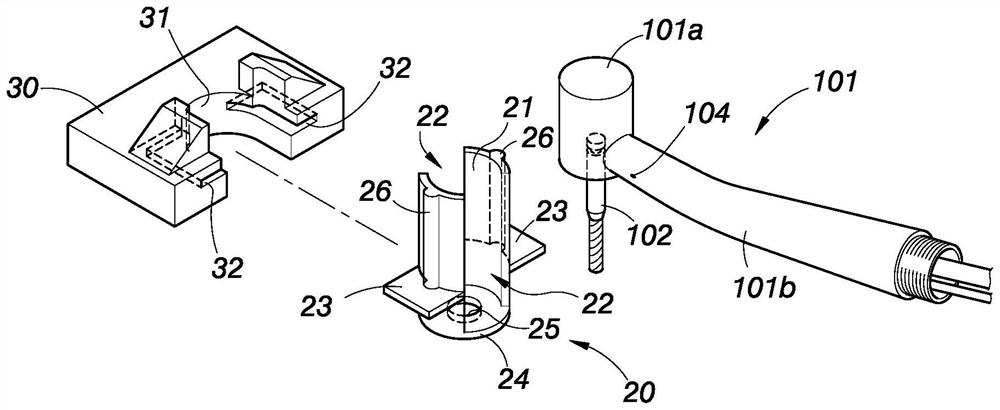

[0033] see image 3 , Figure 4 ,and Figure 5 As shown, it is the first embodiment of the present invention, and the dental implant guiding tool set includes a handpiece 101 , a dental implant guiding sleeve 20 and a dental mold fixing element 30 .

[0034] The mobile phone 101 has a head 101a for replacing the cutter 102 and providing power for the cutter 102, and a connecting handle 101b connected to the head of the cutter 101a.

[0035] The implant guide sleeve 20 has a machine head guide hole 21 arranged axially corresponding to the shape of the machine head 101a, and at least one side opening 22 on the side of the machine head guide hole 21 corresponding to the connecting handle 101b , two positioning pieces 23 radially arranged on the periphery of both sides of the implant guide sleeve 20 and a limiting plate 24 located at the bottom of the guide hole 21 of the machine head, the center of the limiting plate 24 is provided with a cutter perforation 25, The outer edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com