Patents

Literature

45results about How to "Will not interfere with operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

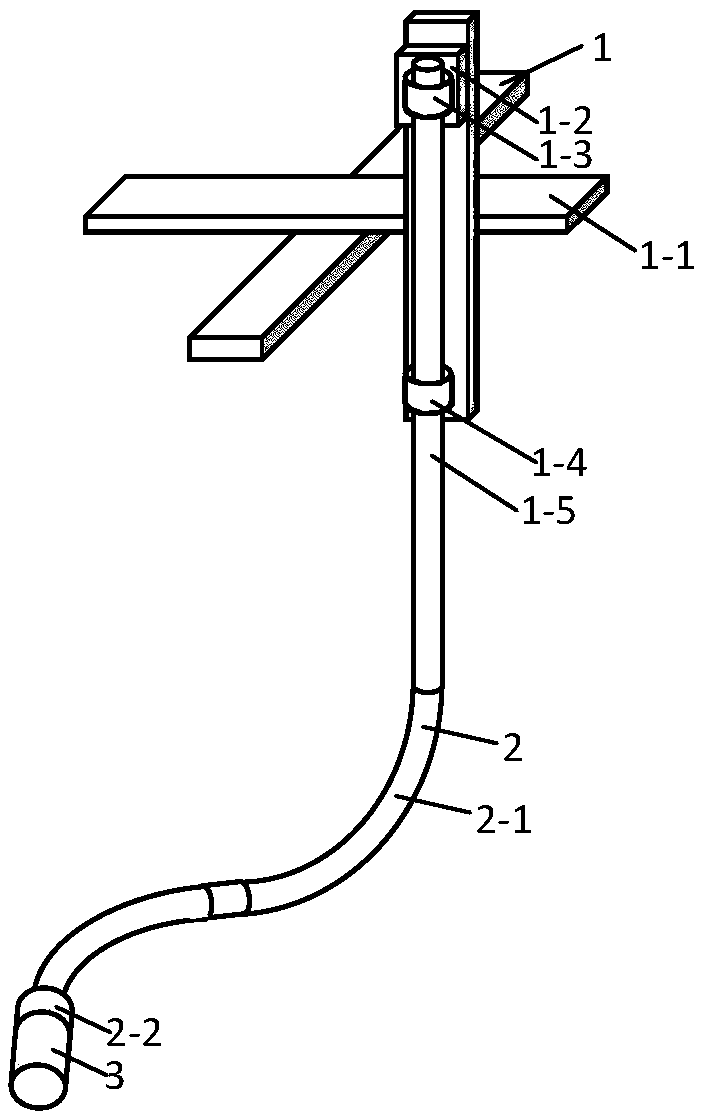

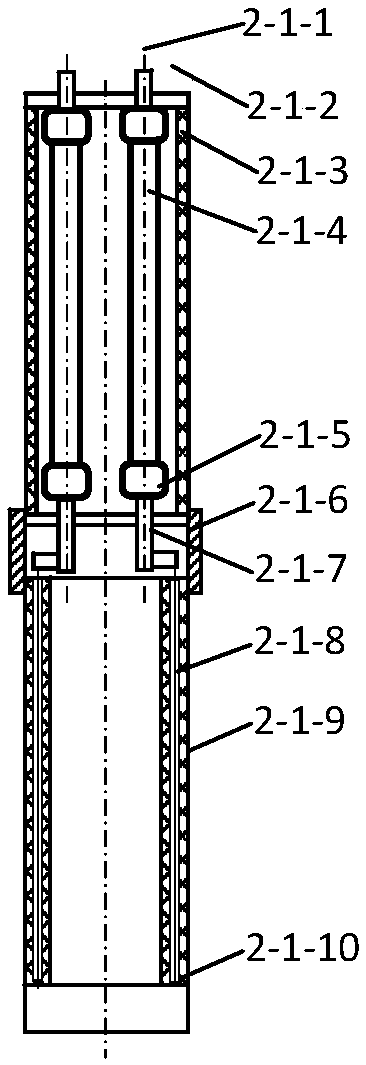

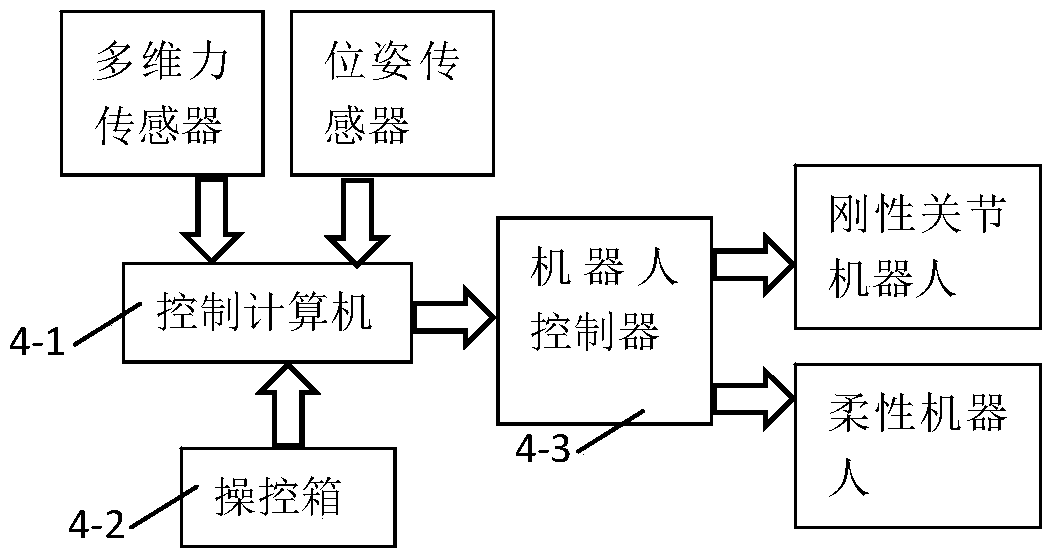

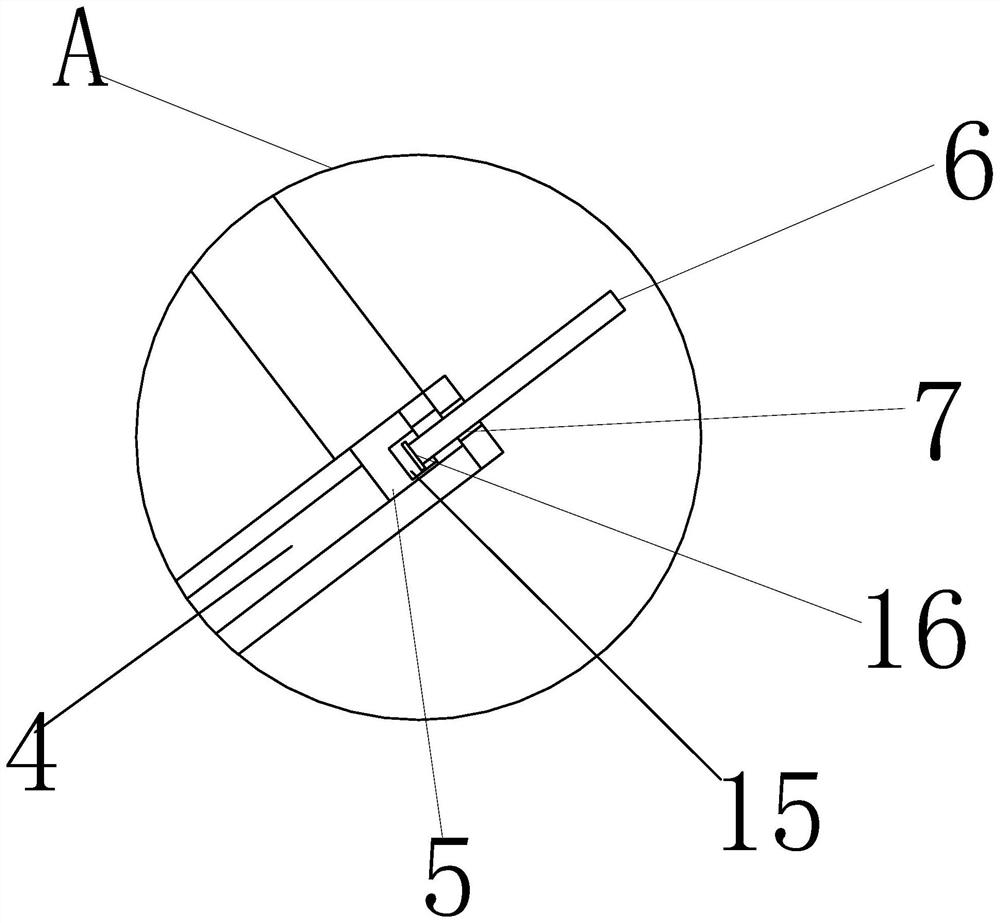

Underwater narrow space detection orientated flexible robot system

ActiveCN108818521ASafe to useSolving Detection ChallengesProgramme-controlled manipulatorAutomatic controlRobotic systems

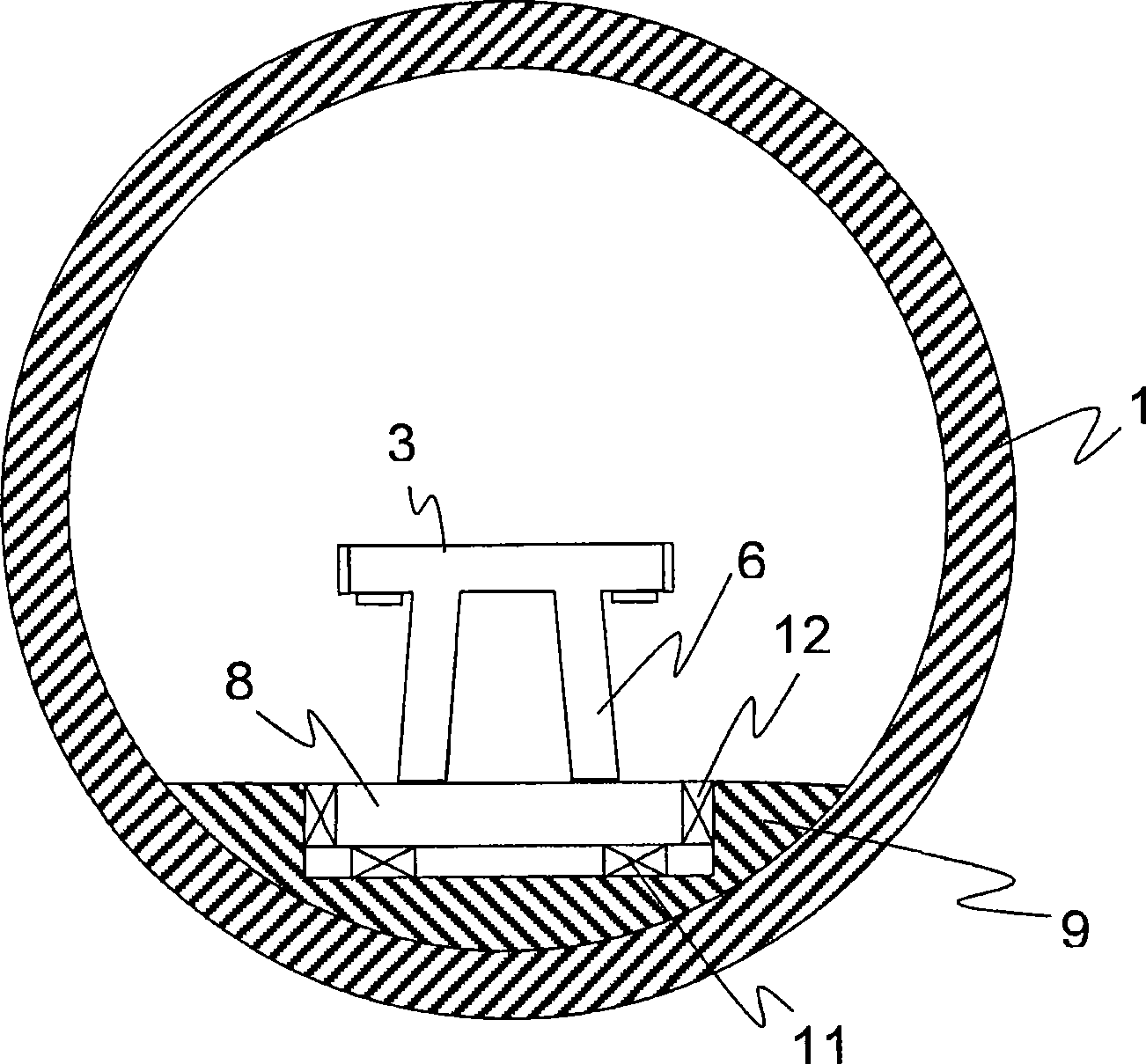

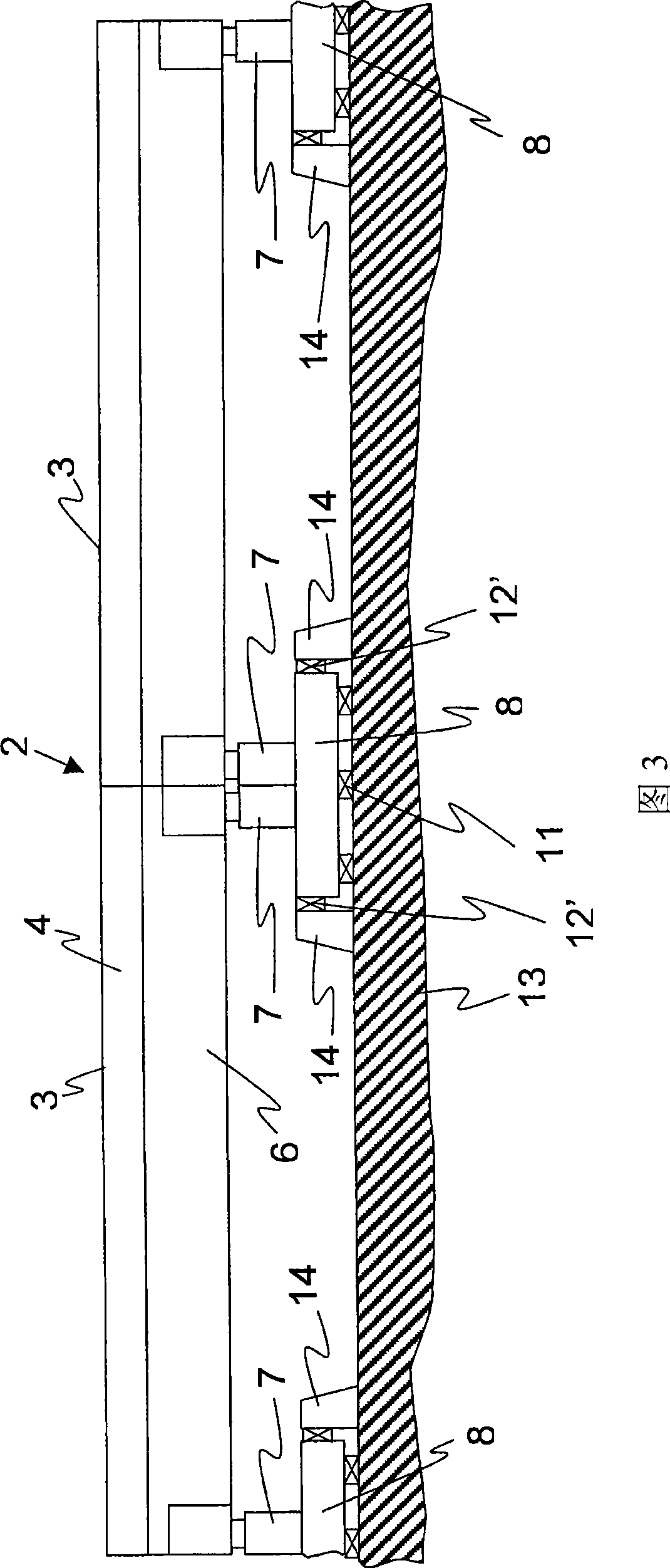

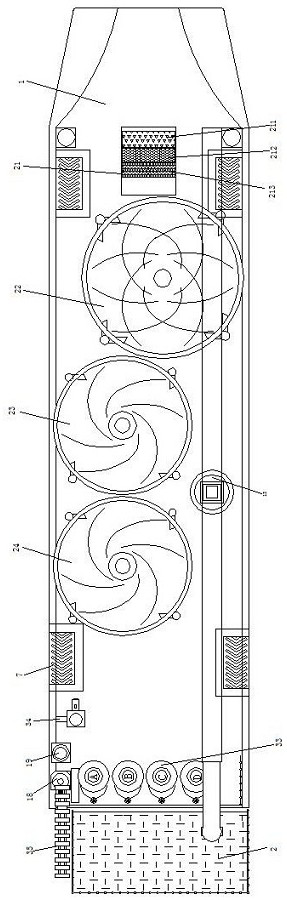

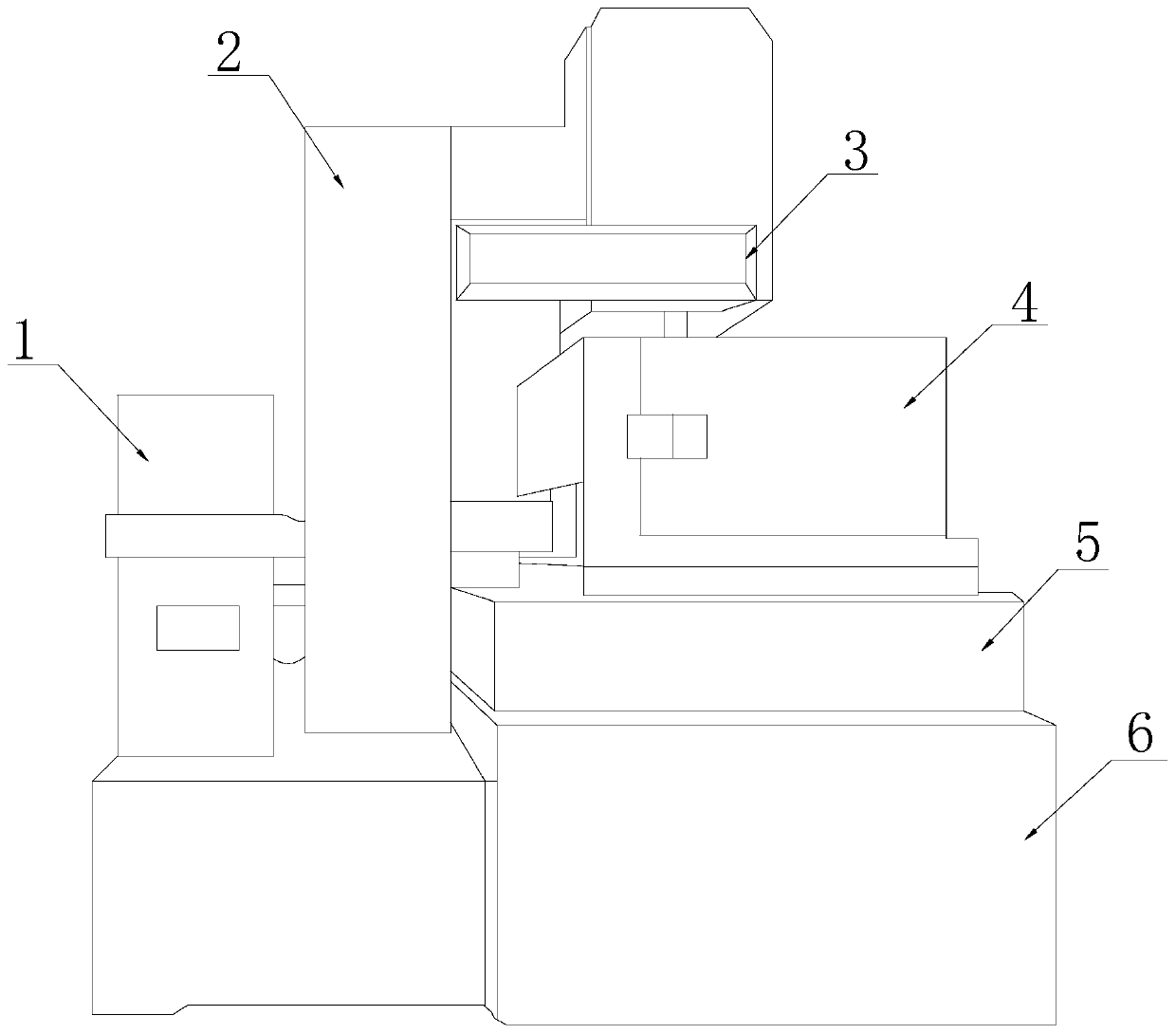

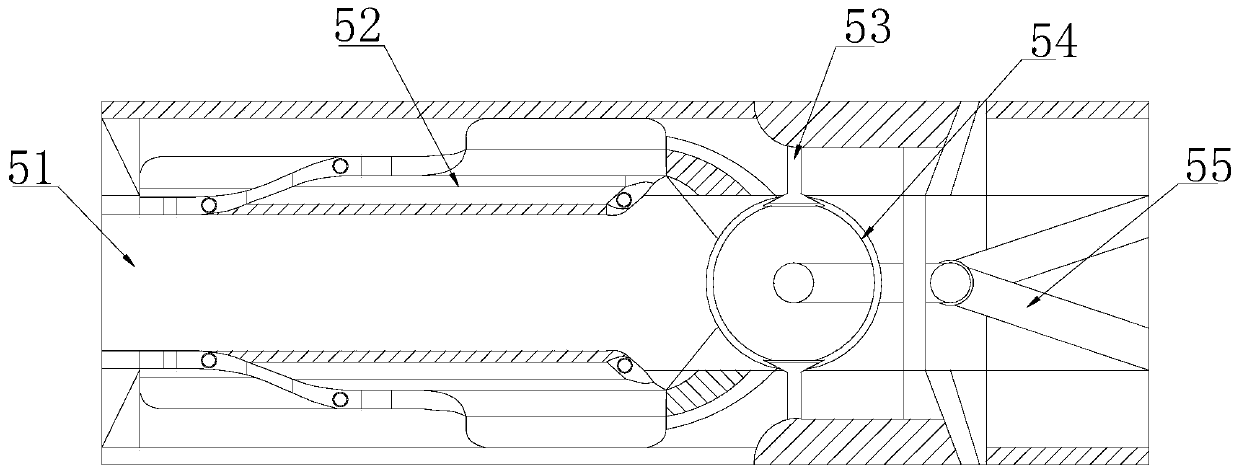

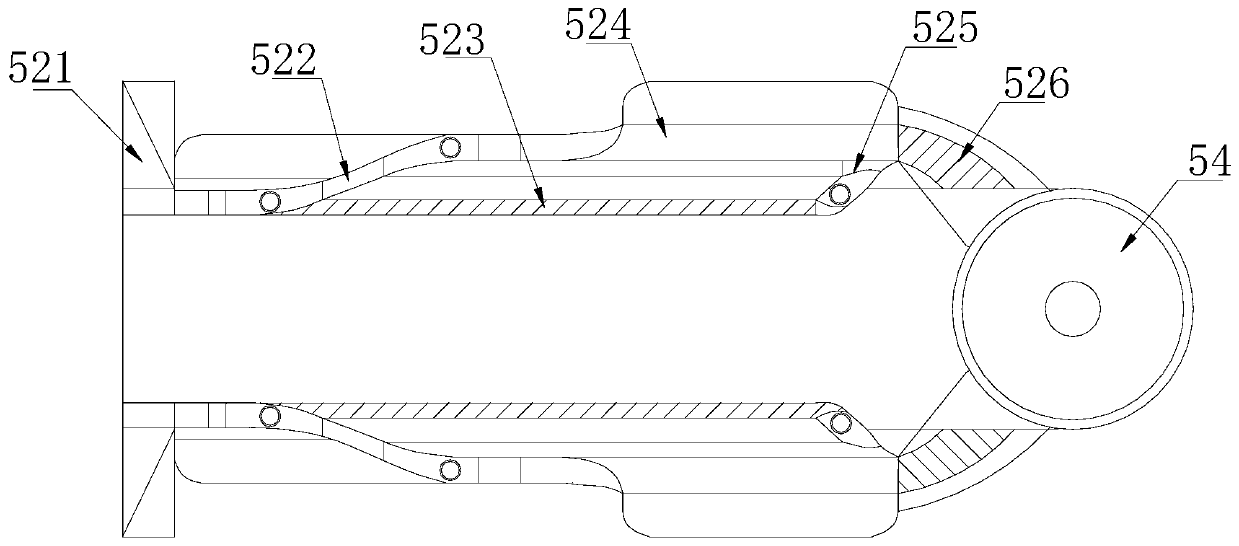

The invention discloses an underwater narrow space detection orientated flexible robot system. The system is characterized by comprising a rigidity multi-joint robot, a flexible robot, an underwater camera and a control system; the rigidity multi-joint robot, the flexible robot and the underwater camera are connected in series sequentially, the flexible robot is formed by series-connection of multiple flexible motion units, each flexible motion unit adopts a hollow flexible framework and a pneumatic manual muscle flexible driver, and multi-freedom-degree space flexible motion is achieved. Theunderwater camera penetrates the narrow space and then is delivered to an underwater position to be detected, the pneumatic manual muscle flexible drive manner is adopted to avoid the problem about the driver underwater seal, the robot is reliable in work and compact in structure, the robot control system can adopt interaction control, program interface control and automatic control manners, the control system can perceive the robot tail end pose and robot and underwater structure contact force, in combination with the structure and drive flexibility of a flexible robot, smooth advancing and retreating of the flexible robot from the narrow space is ensured, the damage to the flexible robot is avoided, operation of an underwater facility is not obstructed, use is safe and reliable, and thedetection problem of the underwater narrow space is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

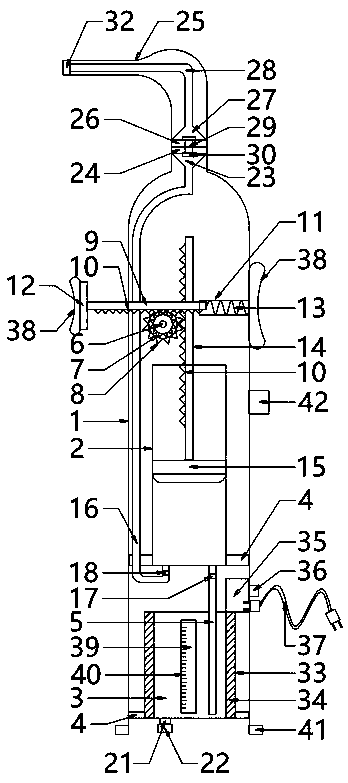

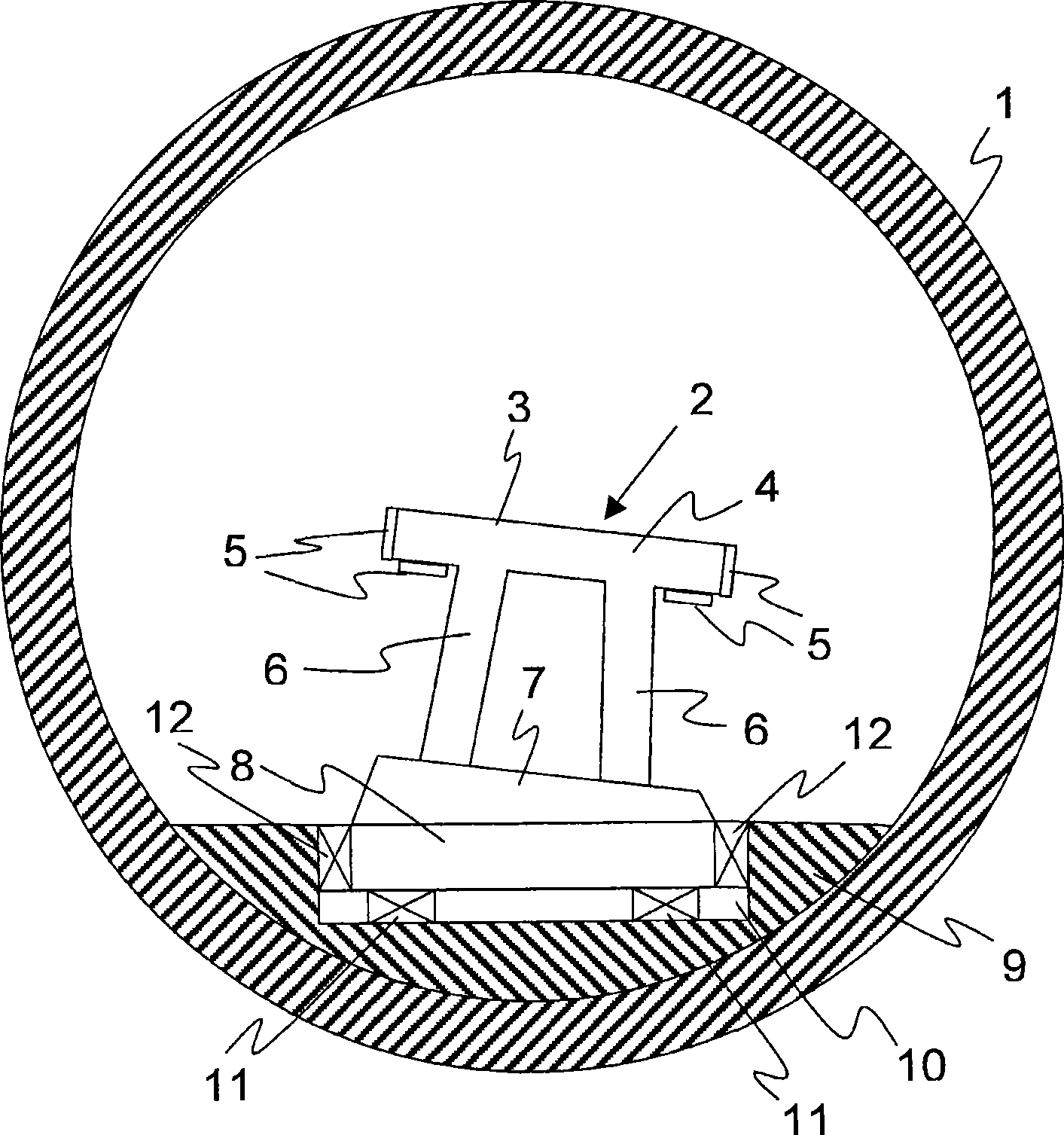

Respiratory medical clinical inhalation drug delivery device

InactiveCN108992749AAdjust the ejection speedTimely replacementMedical devicesMedical atomisersDrugs solutionDrug injection

The invention relates to the technical field of a medical care appliance and particularly relates to a respiratory medical clinical inhalation drug delivery device. The device includes a bottle body,an injection bottle, a storage bottle and a nozzle, wherein the injection bottle and the storage bottle are fixed in the bottle body, a first gear and a second gear are fixed inside the bottle body, the first gear and the second gear are coaxially fixed together, a drug injection pipe and a drug discharge pipe are connected with the bottom of the injection bottle, an uplink one-way valve is arranged inside the injection pipe, a downlink one-way valve is arranged inside the drug discharge pipe, upper and lower rotating pieces are provided with two 90-DEG fan-shaped through holes diagonally, andthe two through holes are staggered from each other. The device is advantaged in that structure design is reasonable, drug solution in the storage bottle can be continuously inhaled into the injection bottle through continuously pressing a push handle, the drug solution in the injection bottle is discharged along the drug pipe with the certain pressure, through turning the nozzle, the width of apassage between an injection hopper and a discharge hopper can be changed, the jet amount of the drug liquid is controlled, and the jet speed of the drug liquid is adjusted.

Owner:郗蓉蓉

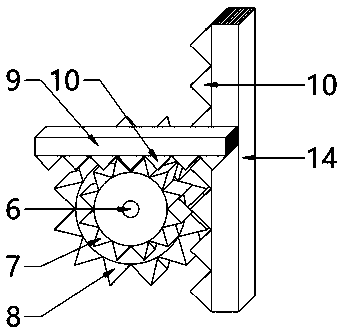

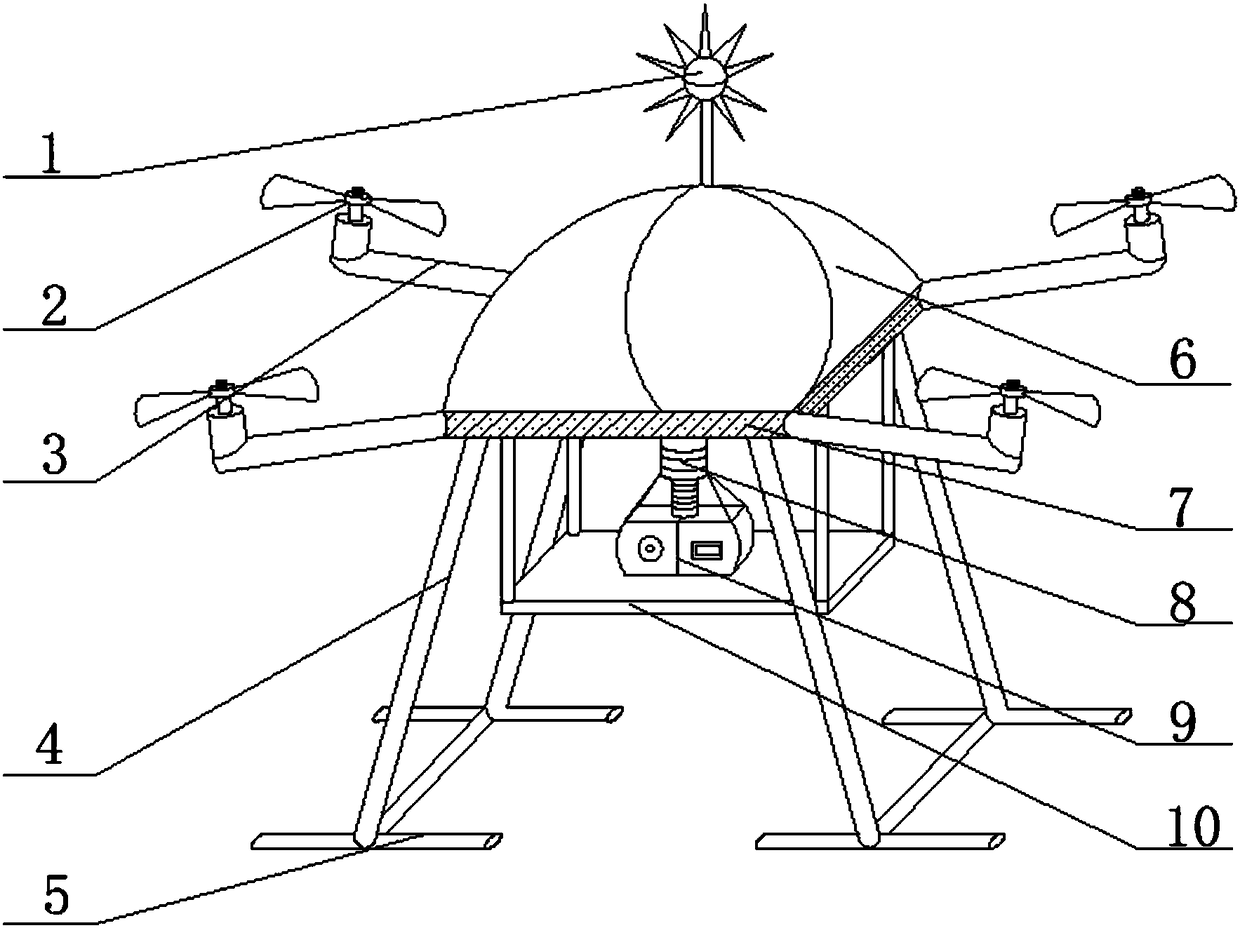

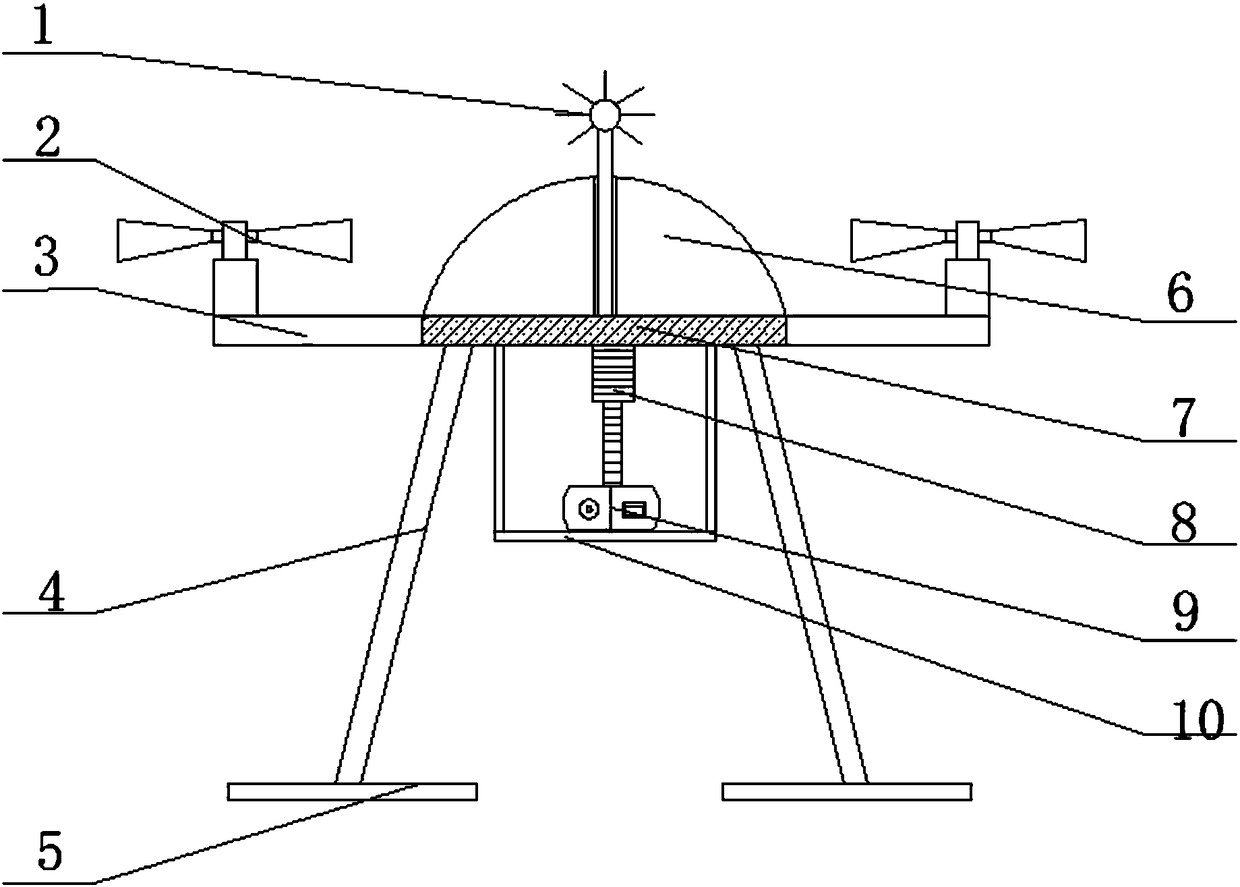

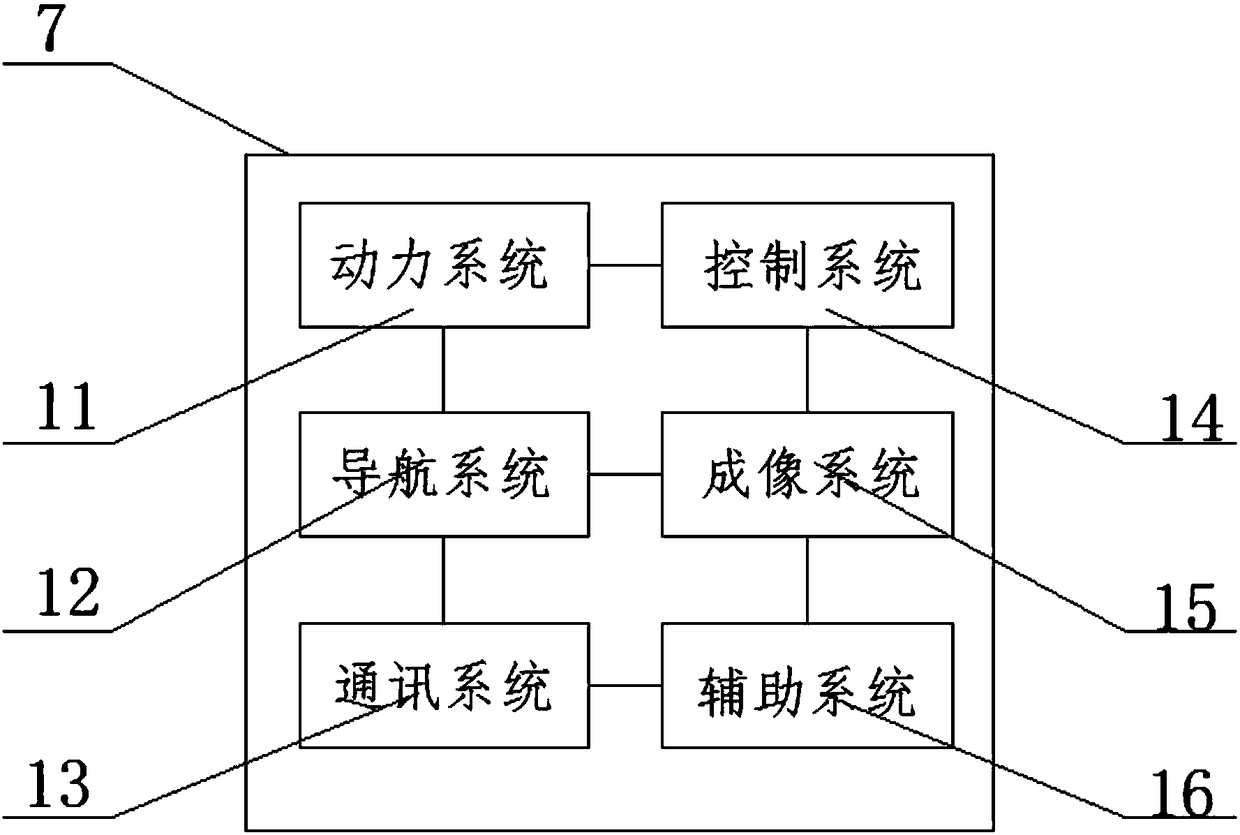

Unmanned aerial vehicle imaging-based bridge crack identification device

InactiveCN108082515AWill not interfere with operationGuaranteed uptimeAircraft componentsTelevision system detailsNumerical controlLightning strike

The invention discloses an unmanned aerial vehicle imaging-based bridge crack identification device, which comprises a lightning rod, propellers, screw rods, support rods, crossbars, a sealing cover,a numerical control platform, a connecting rod, a camera, a fixed platform, a power system, a navigation system, a communication system, a control system, an imaging system, an auxiliary system, a wireless network, a power supply, an led light, an alarm system, a memory and a voice prompt module. The unmanned aerial vehicle imaging-based bridge crack identification device is additionally providedwith the lightning rod, the device is prevented from being damaged by lightning strike when working in a thunderstorm, thus the operation of the internal power system of the device is not interfered,the combination and assembly of the support rods and the crossbars enables the device more stable in storage, the device runs more smoothly, the air resistance is more even, under the adjustment of the control system and the imaging system, the camera can photograph the bridge in all directions, the communication system and the imaging system transmit signals to a receiving station, and thus simpleness and practicality are achieved.

Owner:TIANJIN UNIV

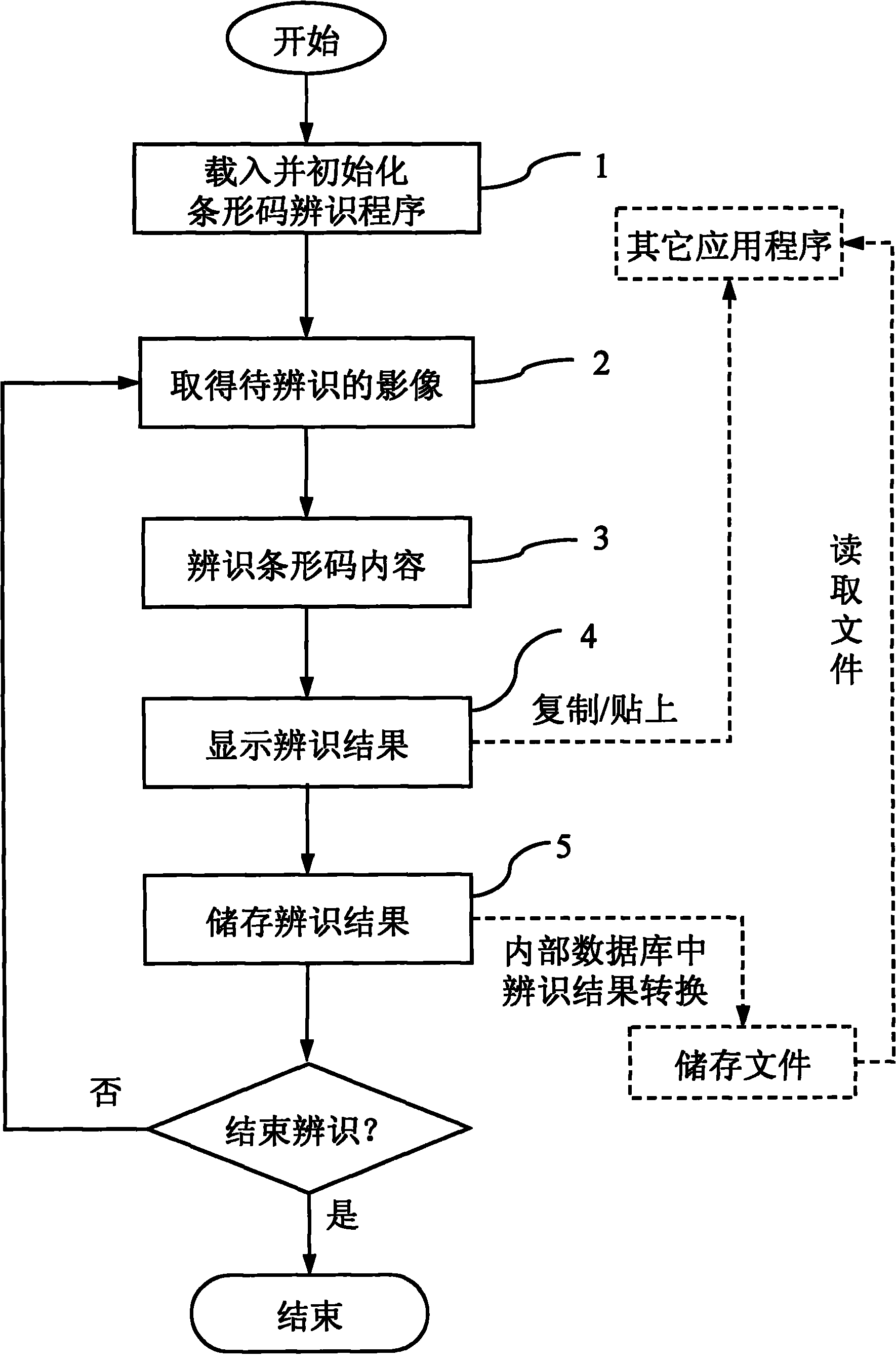

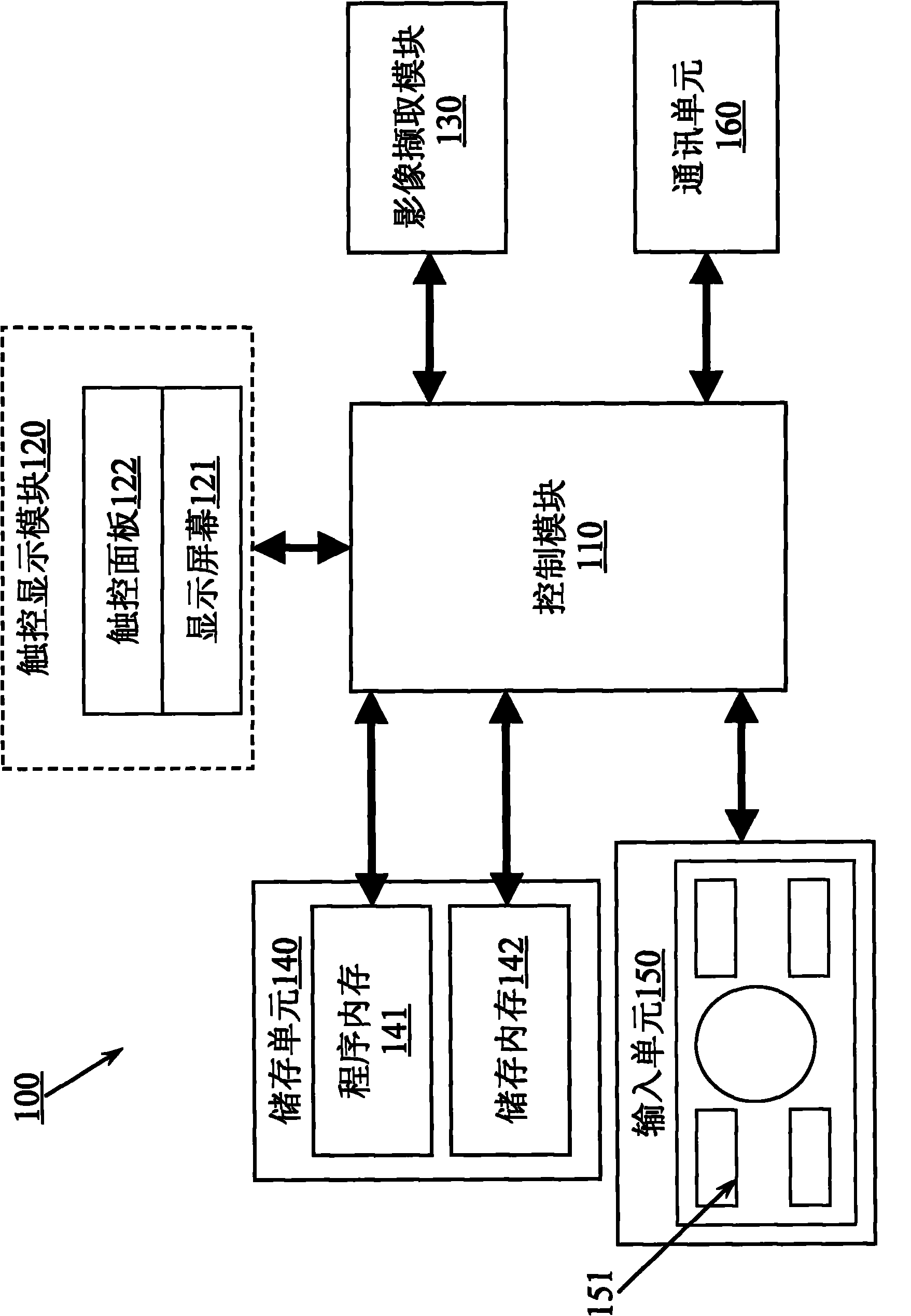

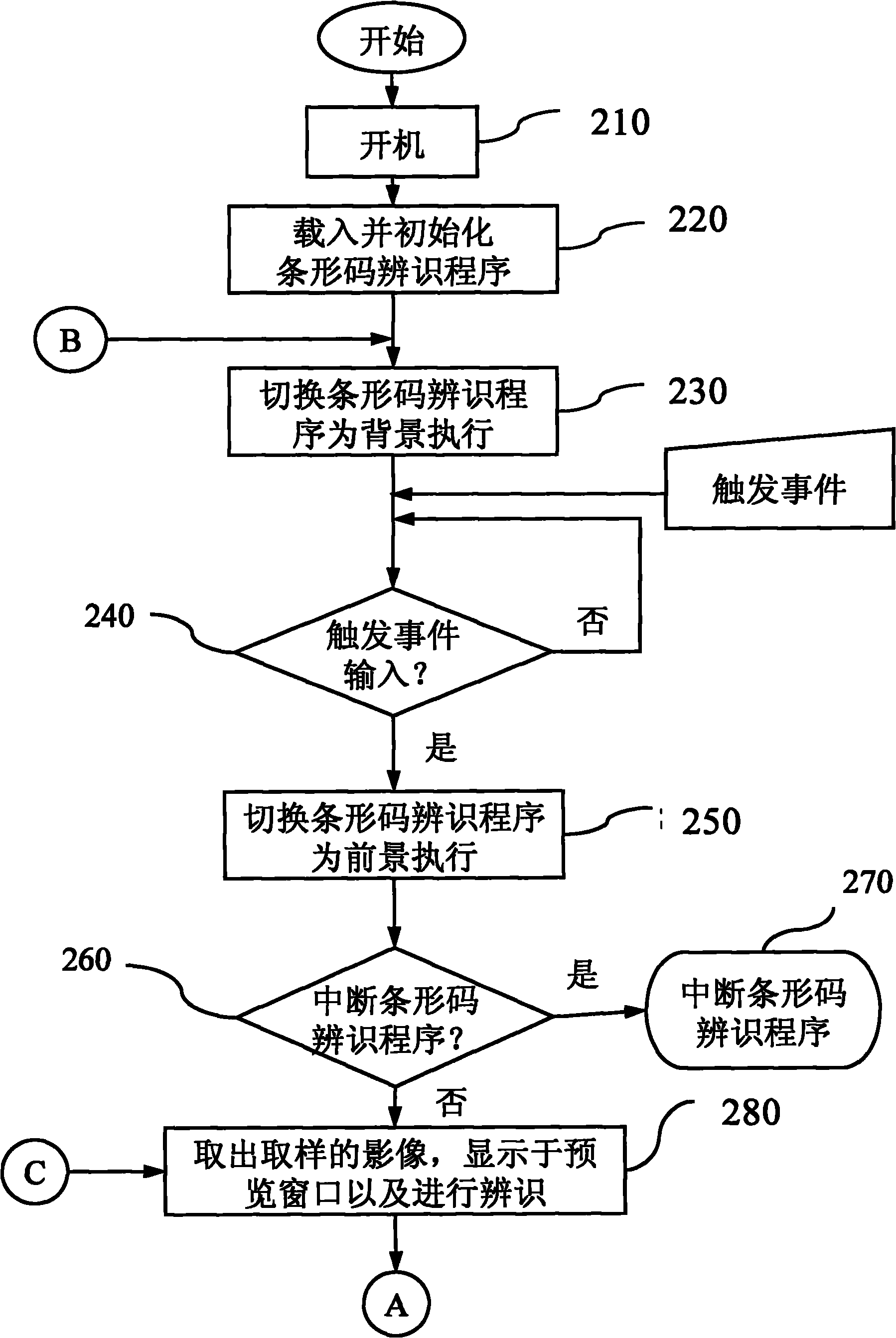

Method for identifying bar code

InactiveCN102034083AWill not interfere with operationReduce difficultyProgram initiation/switchingCharacter and pattern recognitionBarcodeSample image

The invention provides a method for identifying a bar code, and the method is applied to data processing equipment. The method comprises the following steps: after the data processing equipment is started up, a control module loads a bar code identification program from a storage unit and then initializes the program; the control module switches the bar code identification program to a background for execution; the control module continuously monitors whether a trigger event is input into the data processing equipment, and the control module switches the bar code identification program to a foreground for execution when the trigger event occurs; when the bar code identification program is executed at the foreground, an image capture module performs image sampling, and then the control module identifies the sampled image and analyzes the message of the bar code so as to obtain an identification result; and after the control module outputs the identification result to other application programs by the mode of simulating keyboard keys, the control module switches the bar code identification program to the background for execution.

Owner:GETAC TECH CORP

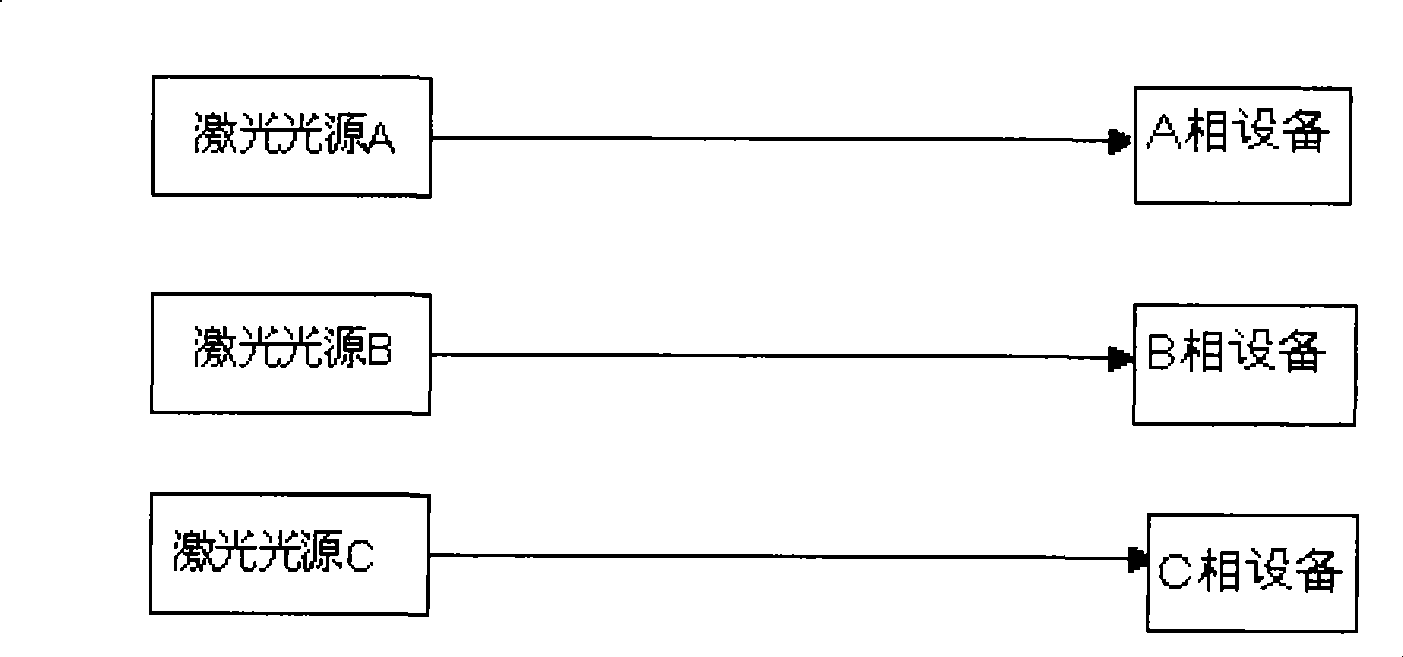

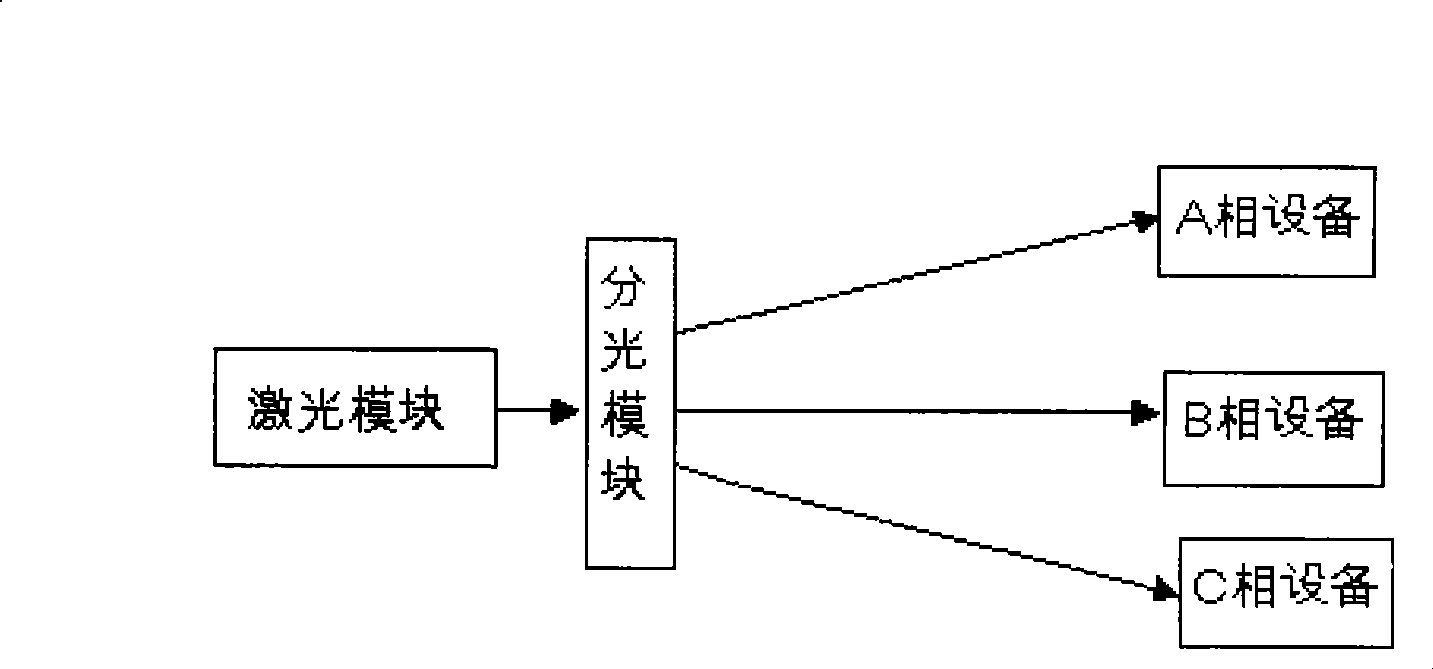

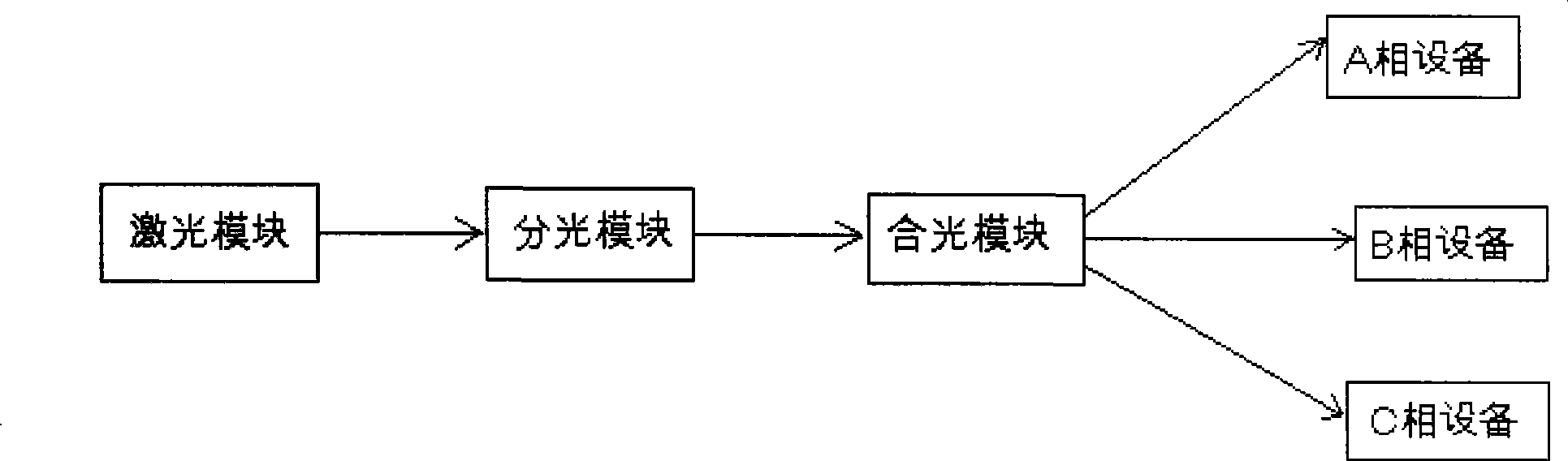

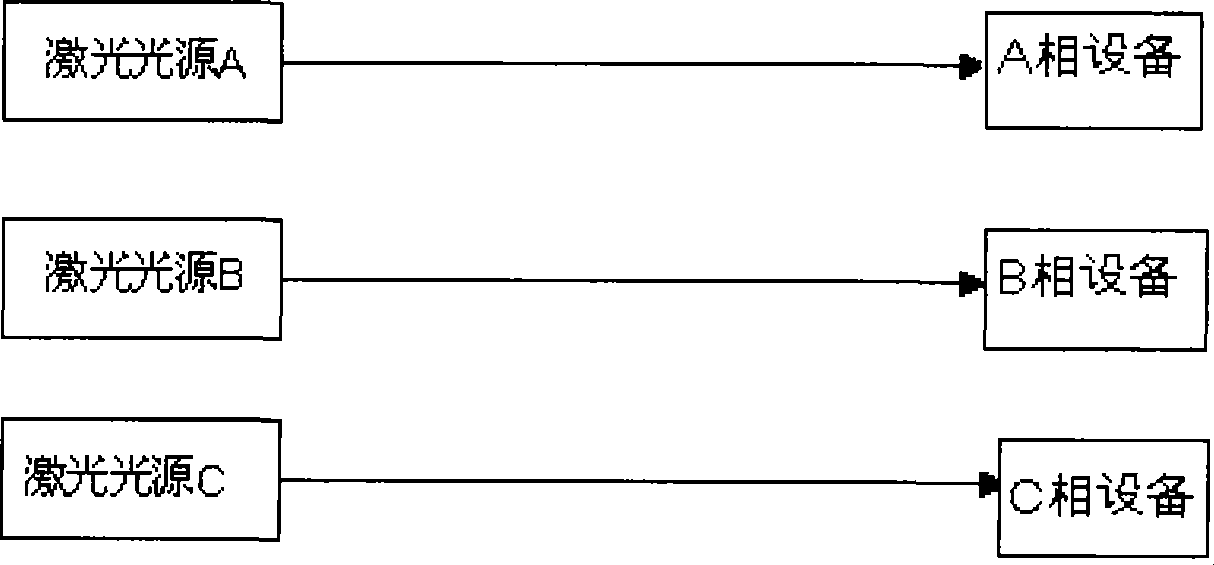

Laser energy supply device

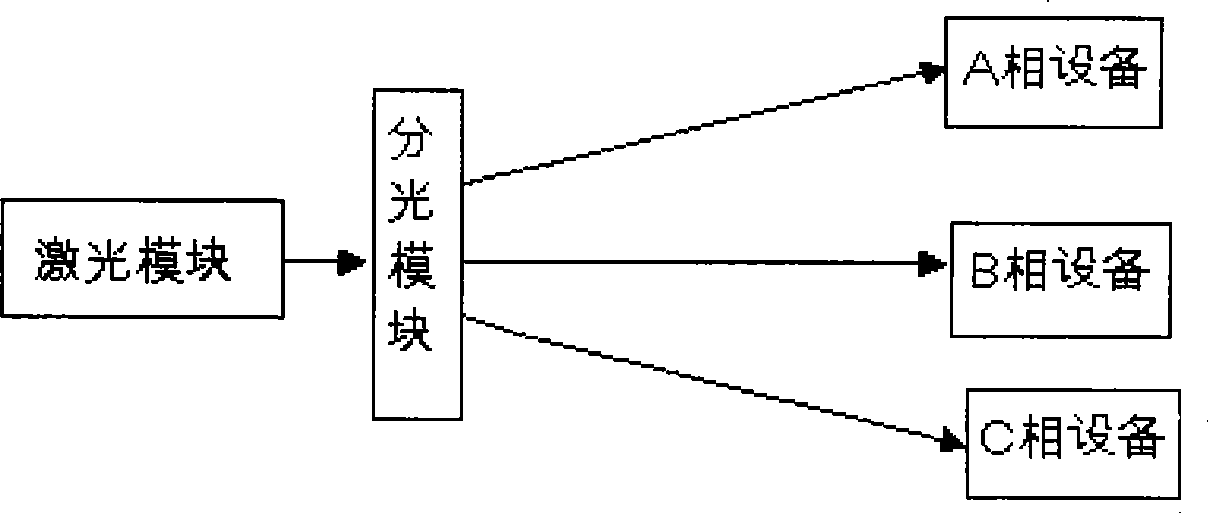

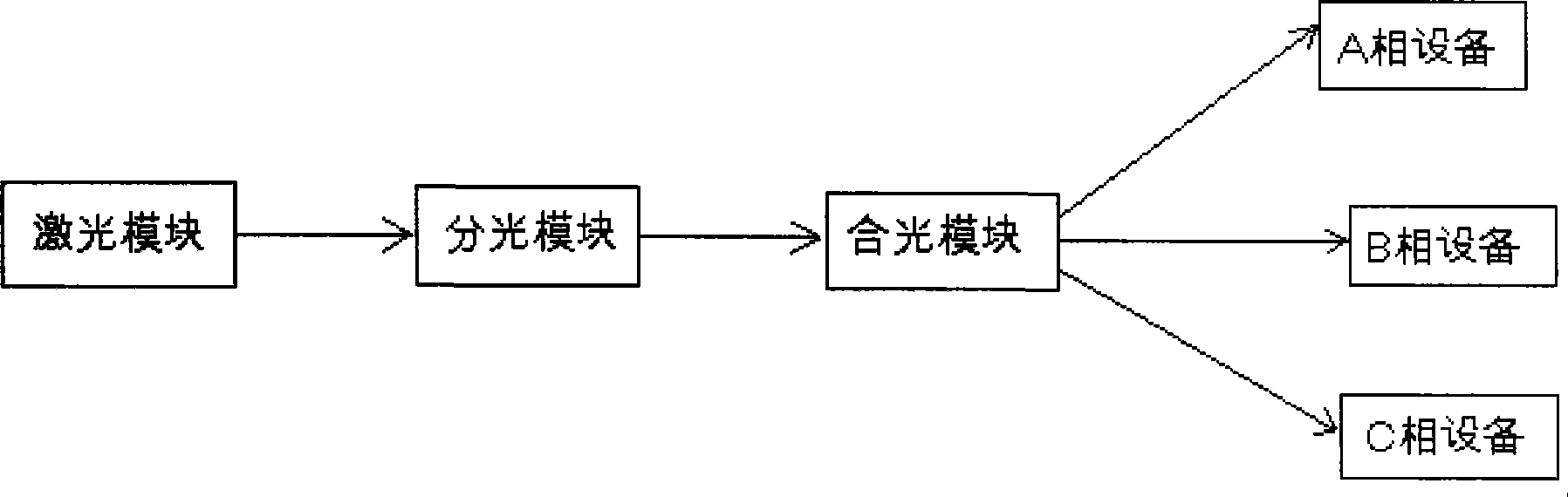

InactiveCN101399465AHigh cost ratioLow costElectromagnetic wave systemCircuit arrangementsComputer moduleEnergy supply

The invention provides a laser energy-supplying device. The device comprises a laser module and a light splitting module; the laser module is connected with the input terminal of the light splitting module by optical fiber. After the laser module outputs laser to the light splitting module, the light splitting module divides the laser into three bunches and transfers the laser to A-phase equipment, B-phase equipment and C-phase equipment respectively. The device can satisfy the requirements of power supply of three-phase load, cost is low, reliability is good, and maintenance is easy.

Owner:WUHAN YANGTZE OPTICAL NETWORK COMM CO LTD

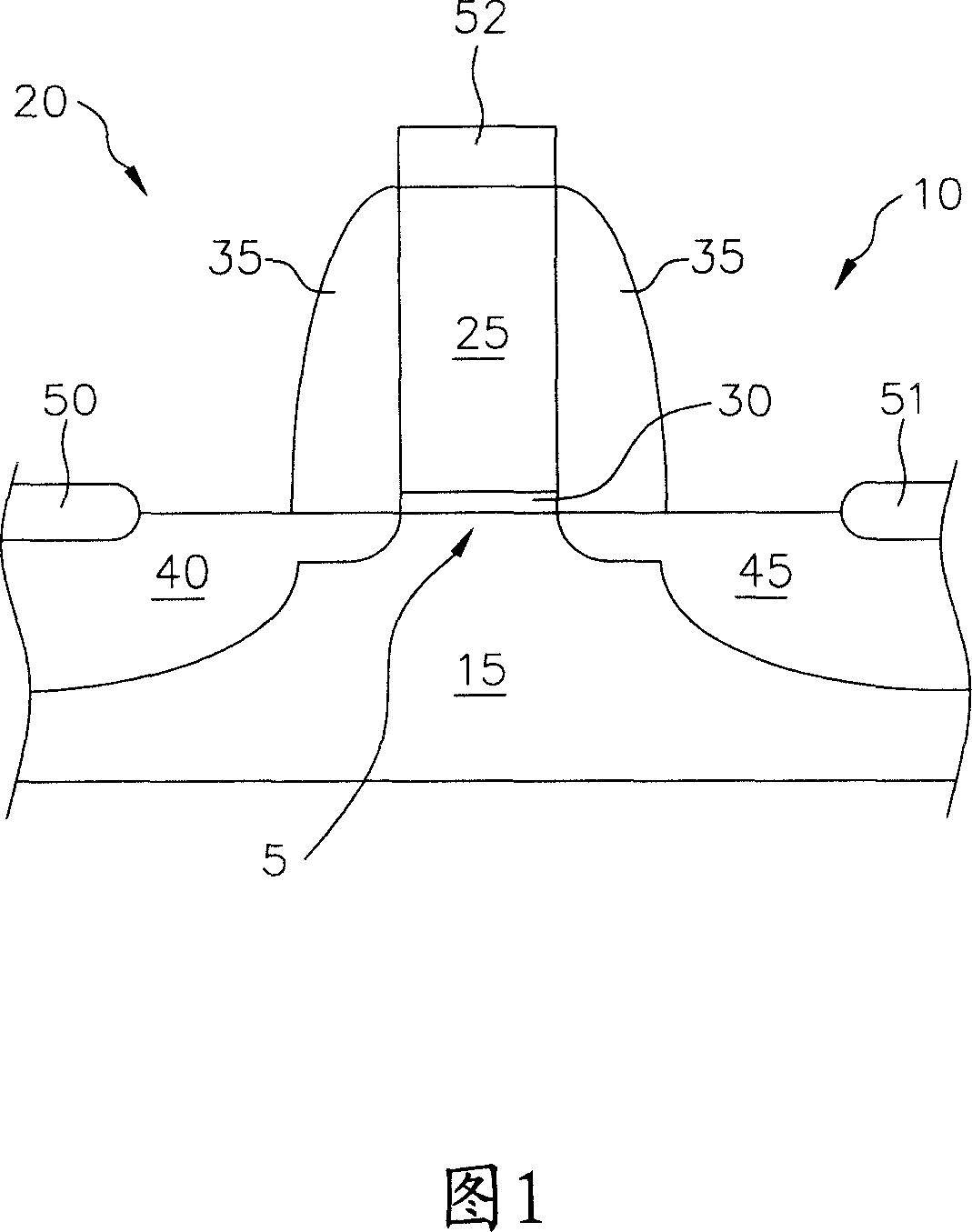

Method of manufacturing strained-silicon semiconductor device

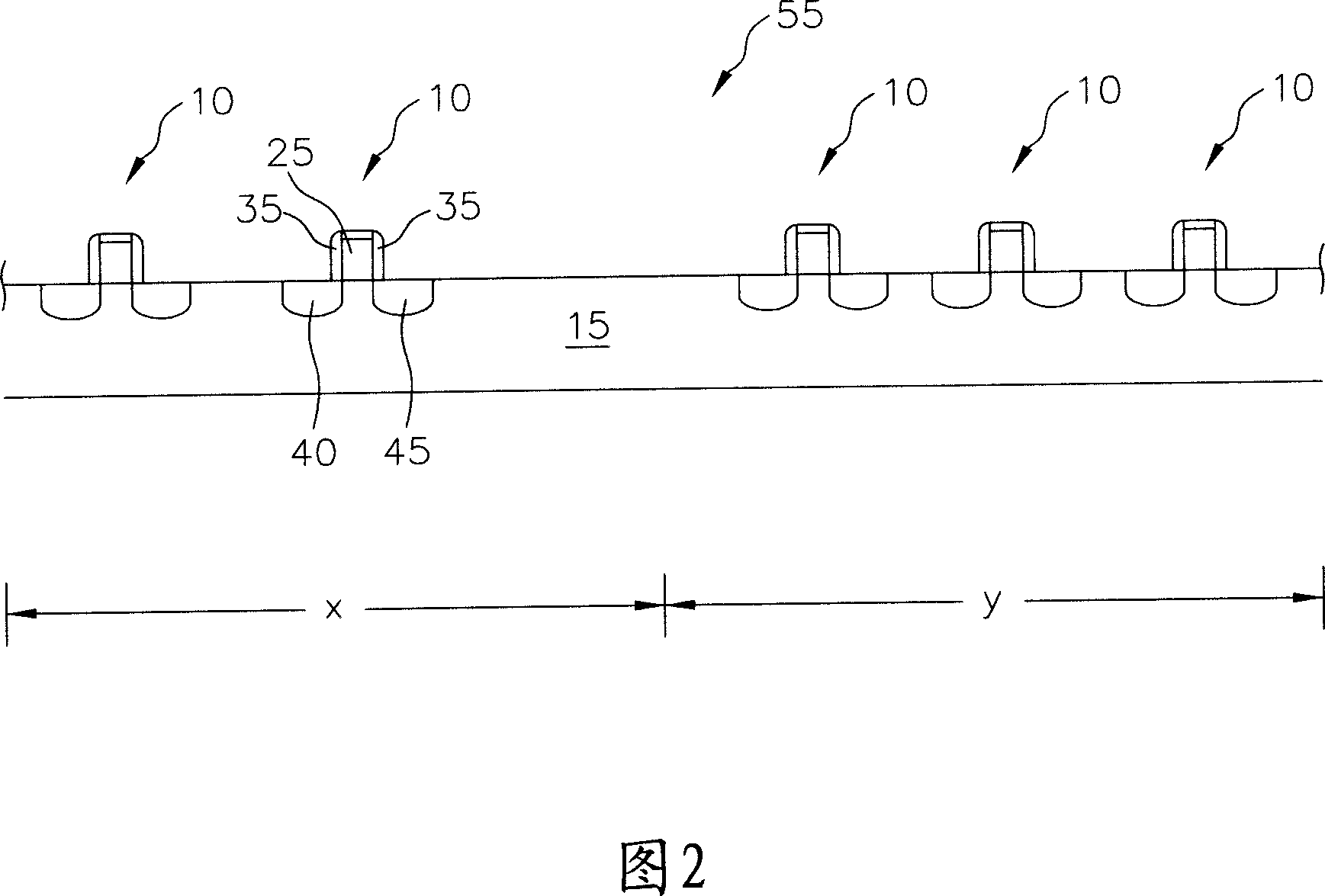

InactiveCN1971878AWill not interfere with operationReduce or eliminate local loading effectsSolid-state devicesSemiconductor/solid-state device manufacturingSiliconStrained silicon

A method for fabricating a strained-silicon semiconductor device to ameliorate undesirable variation in epitaxial film thickness. The layout or component configuration for the proposed semiconductor device is evaluated to determine areas of relatively light or dense population in order to determine whether local-loading-effect defects are likely to occur. If a possibility of such defects occurring exists, a dummy pattern of epitaxial structures may be indicated. If so, the dummy pattern appropriate to the proposed layout is created, incorporated into the mask design, and then implemented on the substrate along with the originally-proposed component configuration. The present invention can decrease or eliminate local load effect without interfering the operation of the semiconductor device.

Owner:TAIWAN SEMICON MFG CO LTD

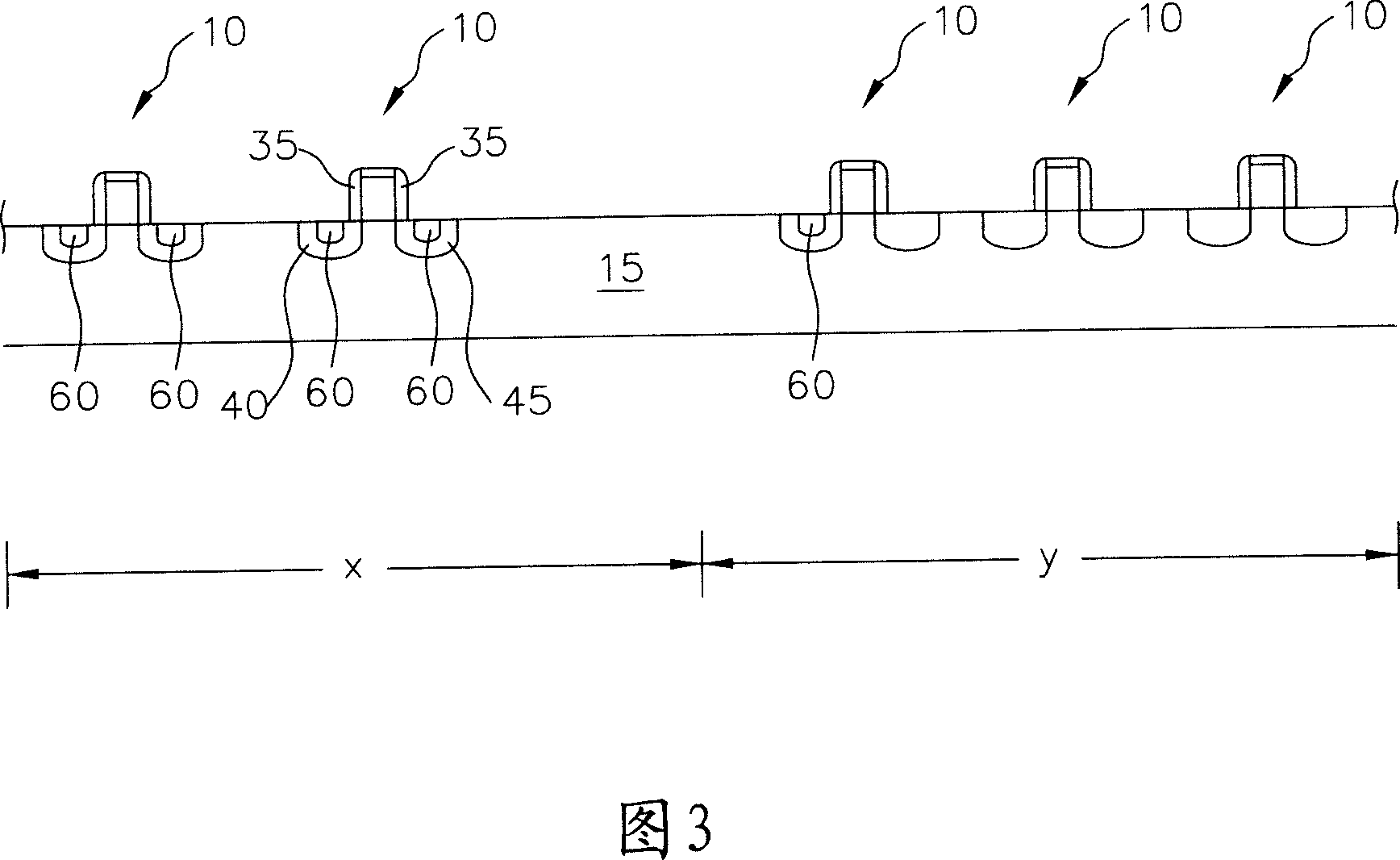

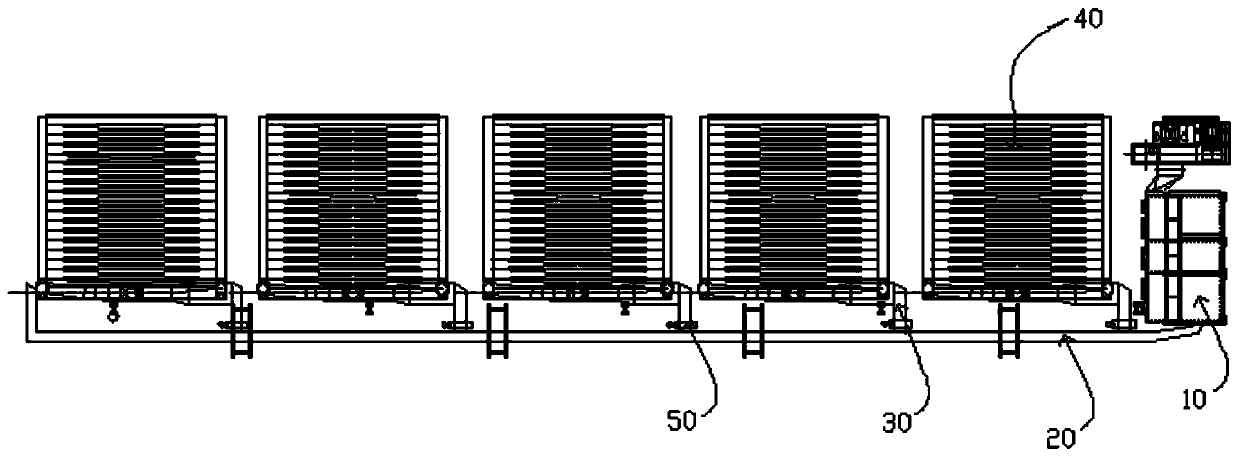

Dust removal system for casting workshops

The invention belongs to the technical field of casting equipment, and particularly relates to a casting workshop dust removal system. The casting workshop dust removal system comprises a dust remover, a dust removal main pipe, a plurality of dust removal branch pipes, a plurality of telescopic dust accumulation covers, a control system and a frequency converter; the dust remover is arranged on one side of a workshop; one end of the dedust removal main pipe is communicated with the dust remover; a plurality of dust suction openings are formed in the dust removal main pipe at intervals; one endof each dust removal branch pipe is communicated with a dust suction opening in the corresponding dust removal branch pipe, and the other end is communicated with a corresponding telescopic dust accumulation cover; the plurality of dust accumulation covers are arranged in the workshop at intervals, and a smoke sensor is arranged in each telescopic dust accumulation cover; a signal input end of the control system is connected with a signal output end of each smoke sensor; a signal input end of the frequency converter is connected with a signal output end of a controller. The casting workshop dust removal system is used in traditional casting workshops, adoption of the dust remover, the telescopic dust accumulation covers and the control system is capable of realizing collecting and treating of smoke dust generated by air gouging, welding and relief grinding in the workshop, and discharging of the treated smoke dust into the atmosphere, and pollution to the atmosphere is reduced.

Owner:KOCEL STEEL

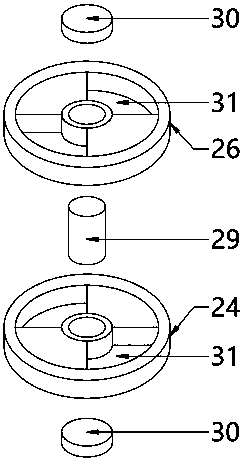

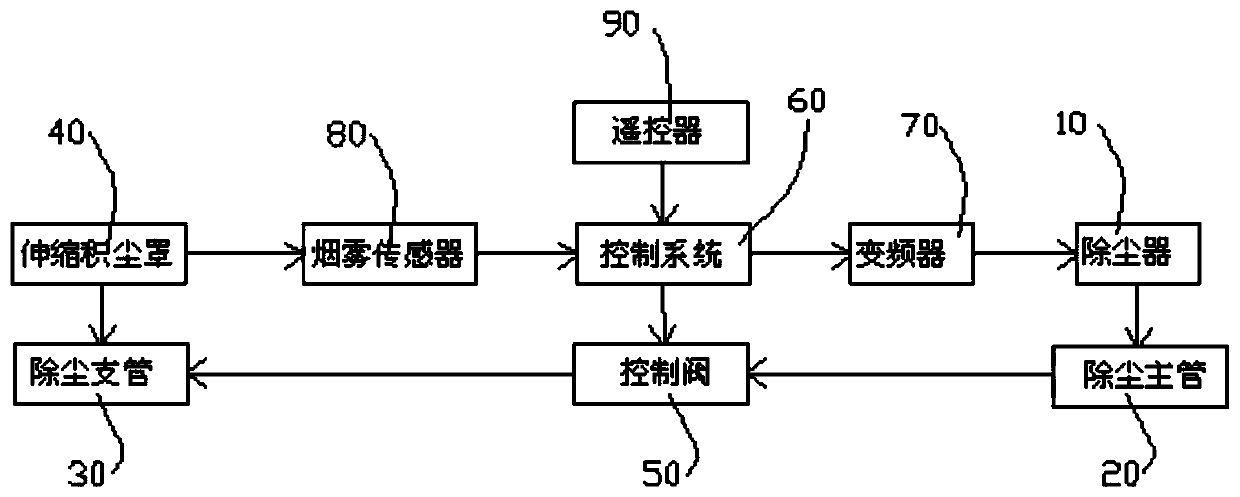

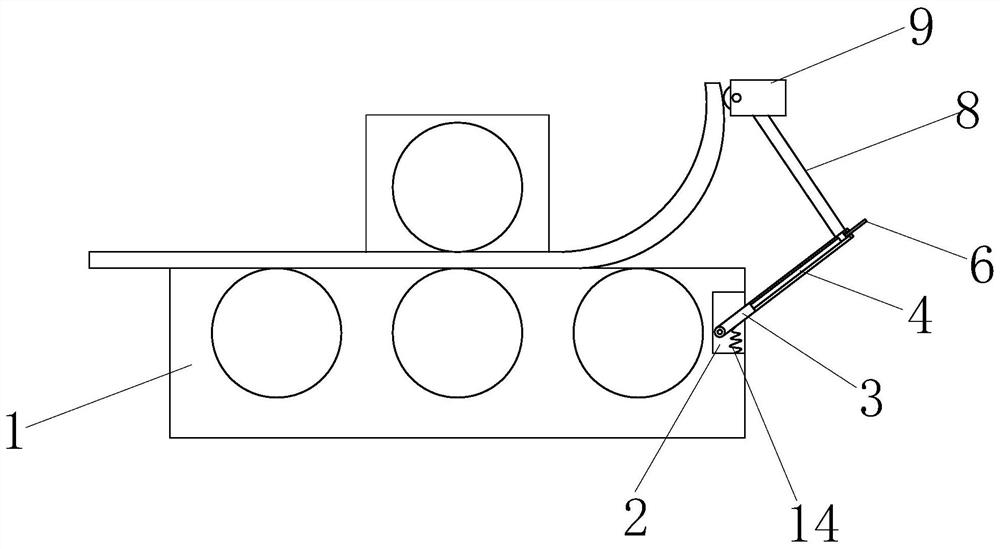

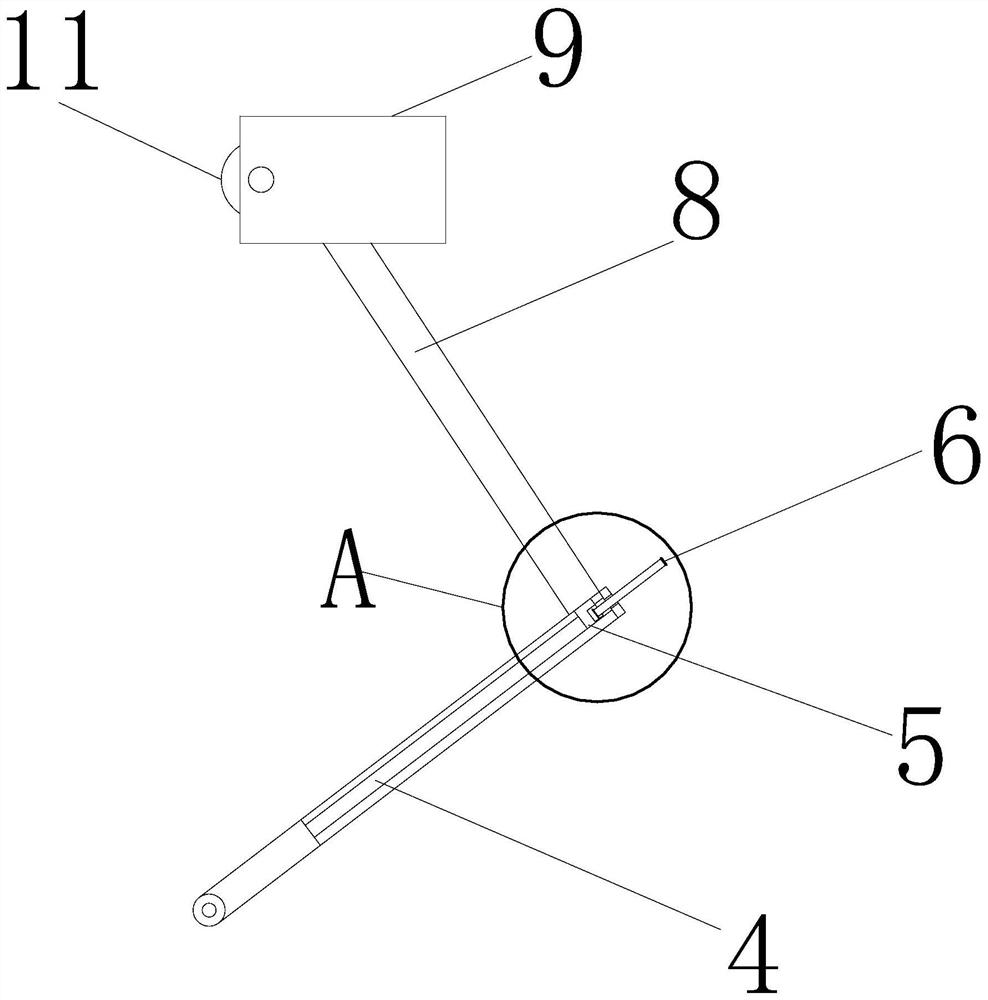

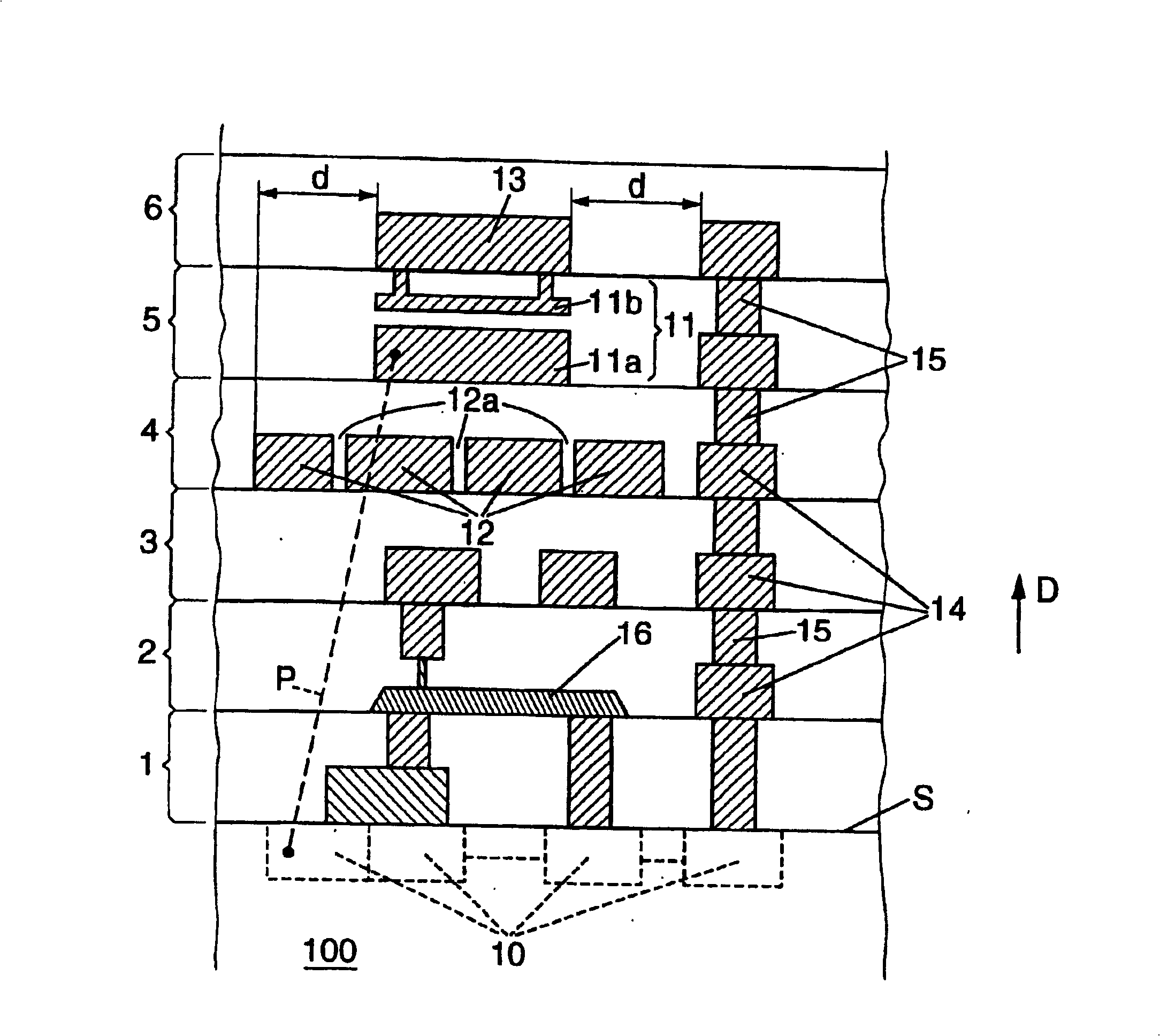

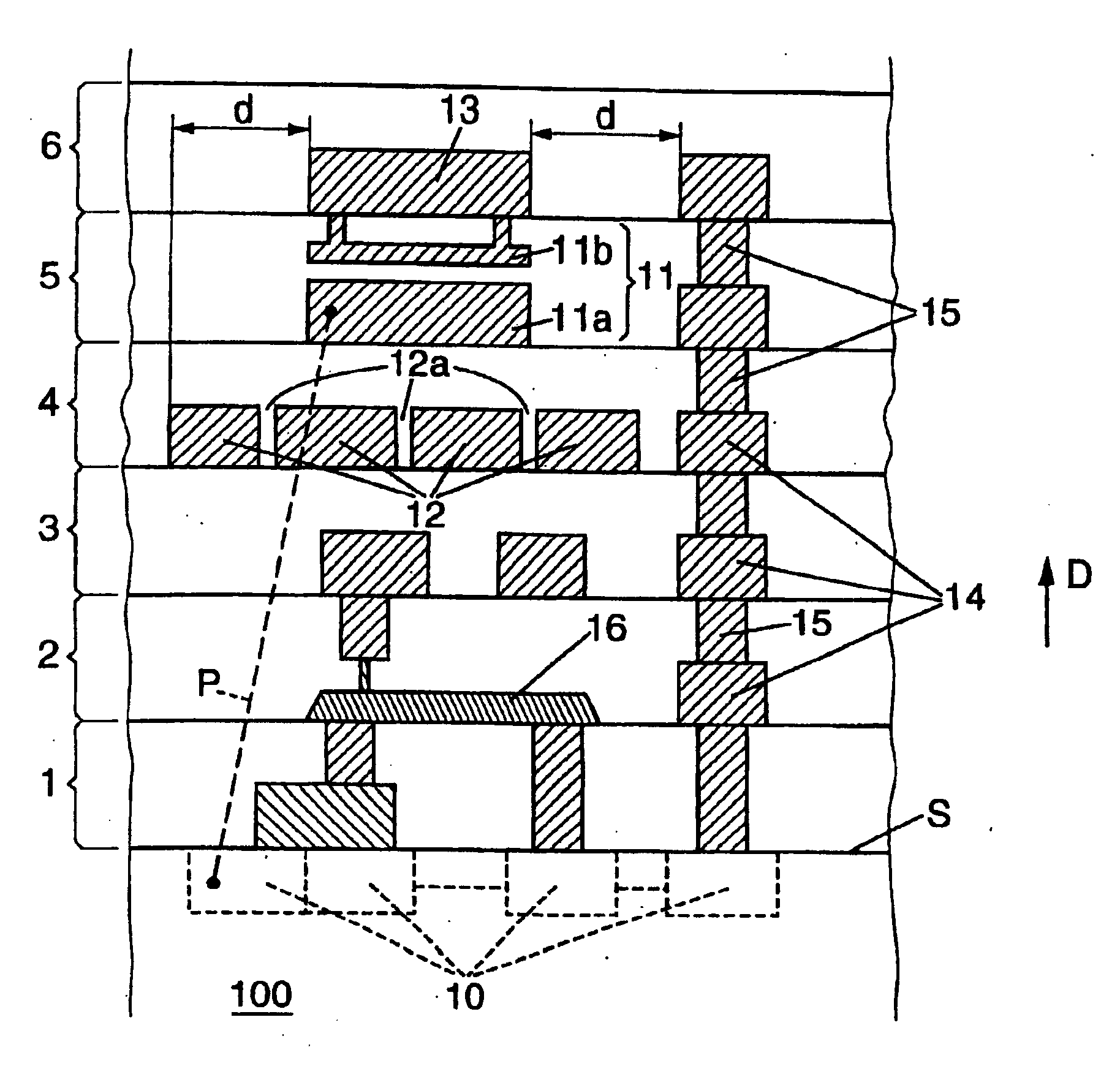

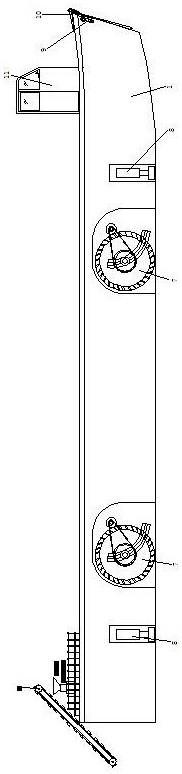

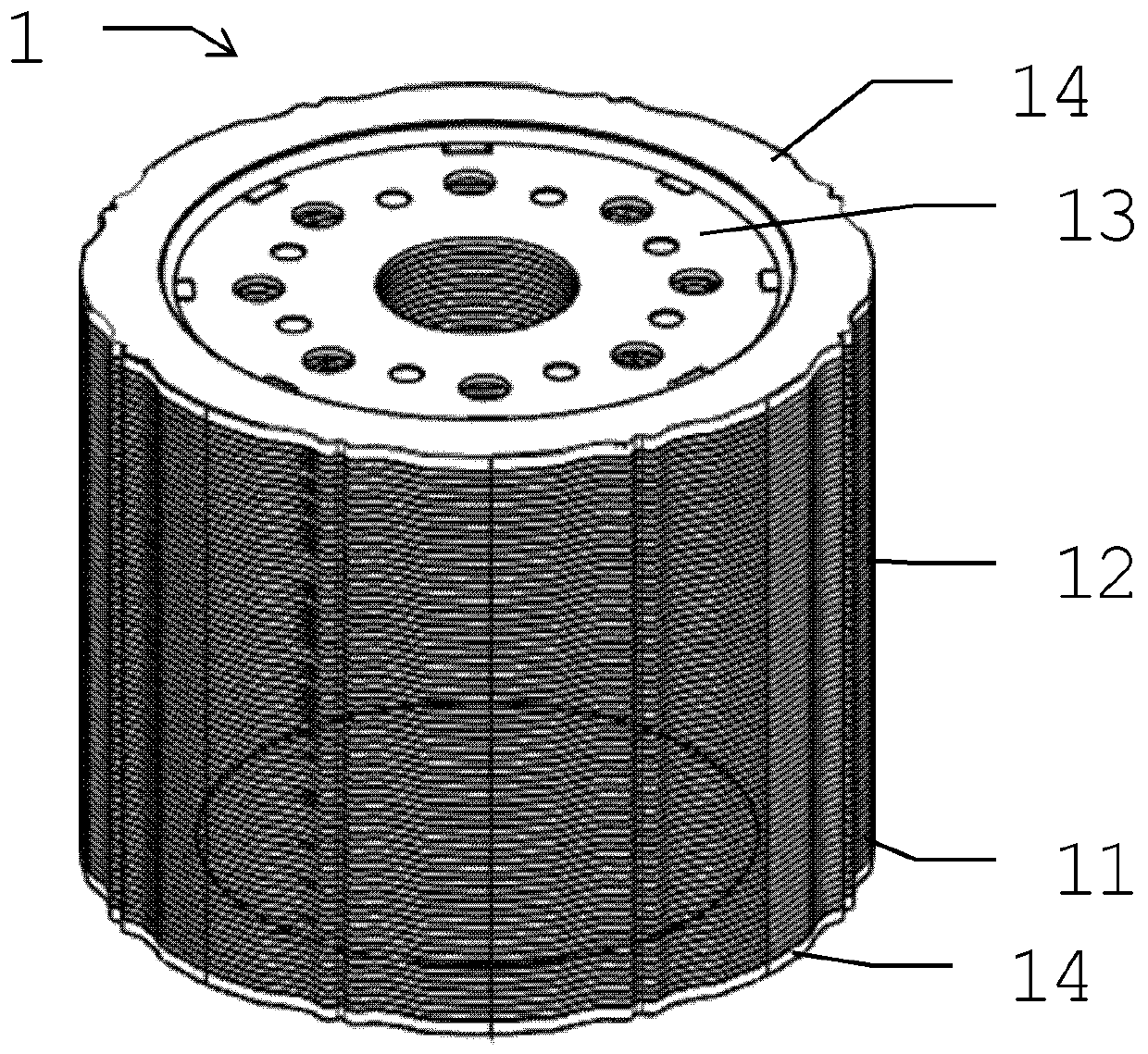

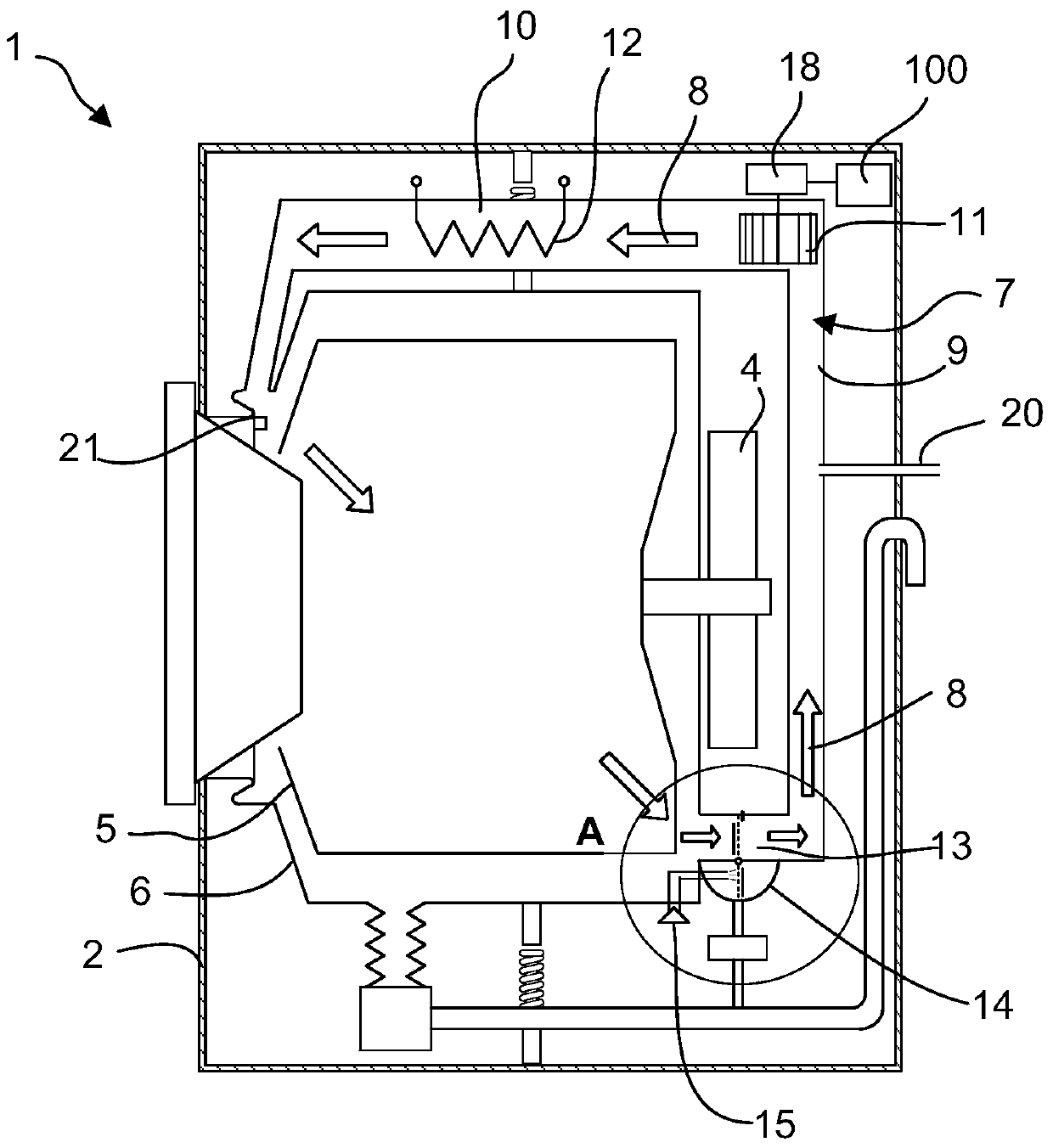

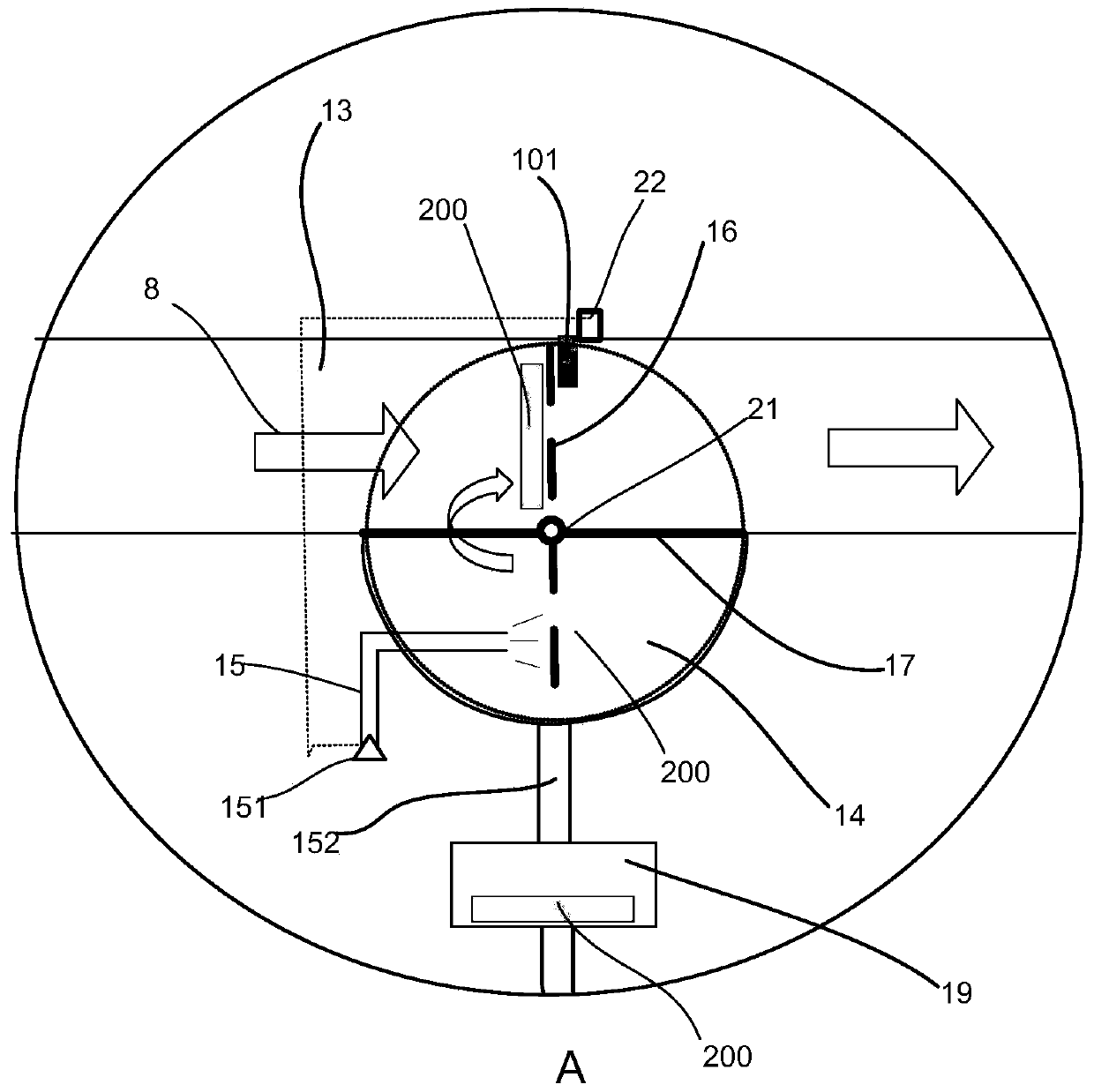

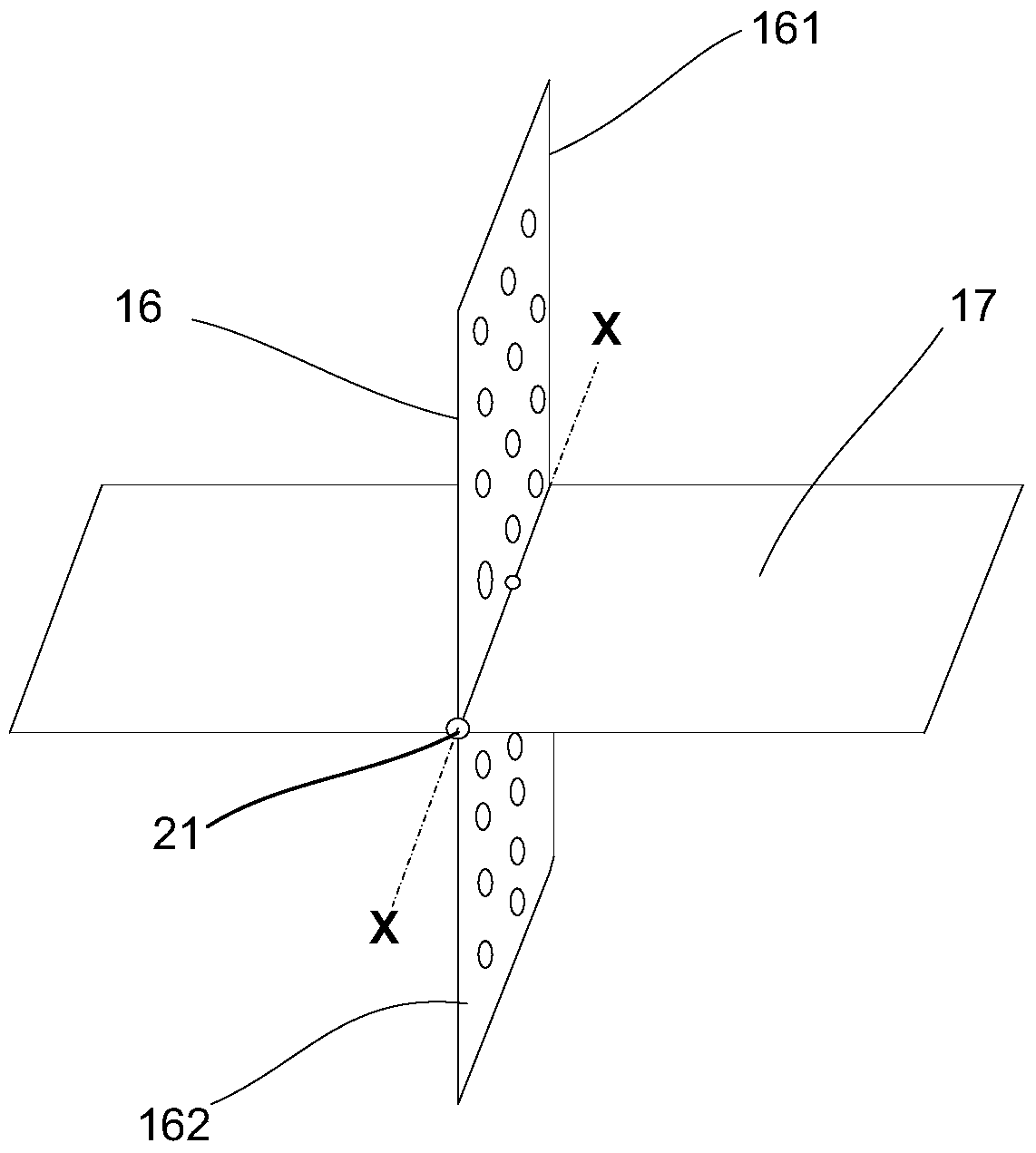

Vertical axis wind turbine

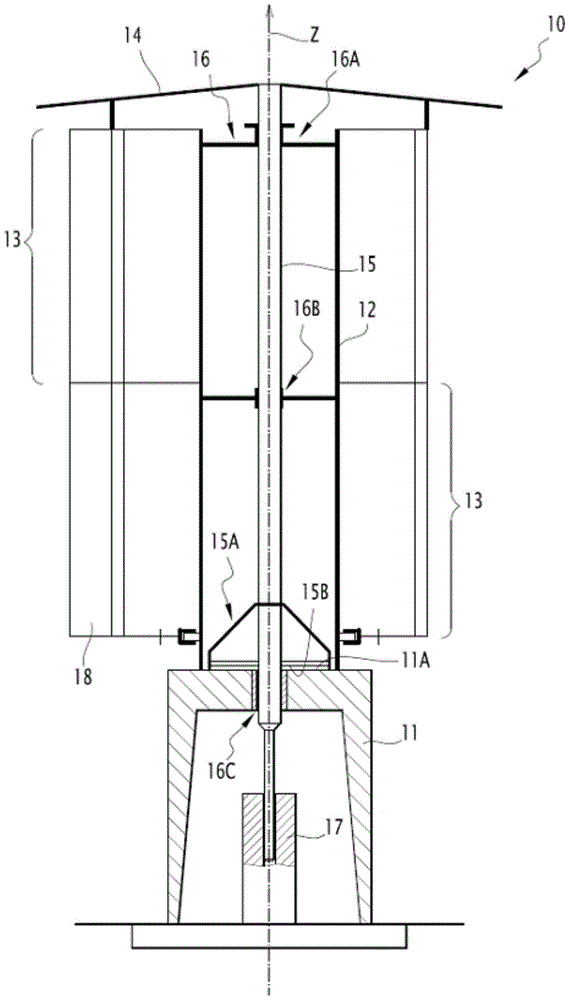

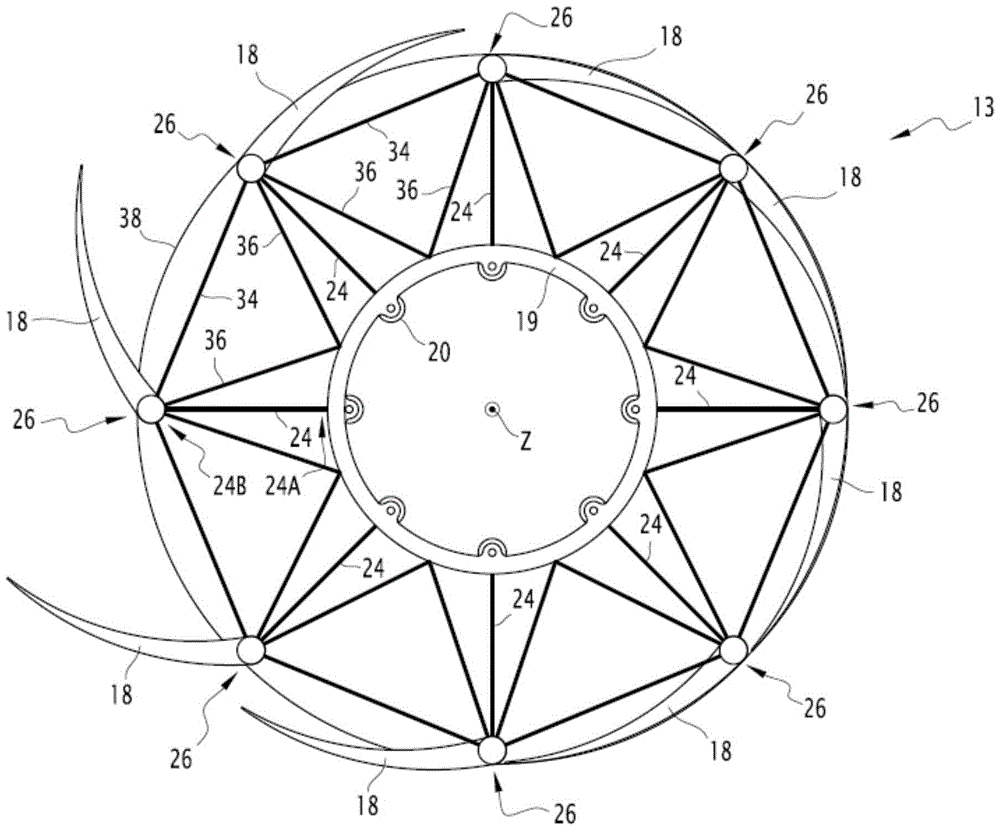

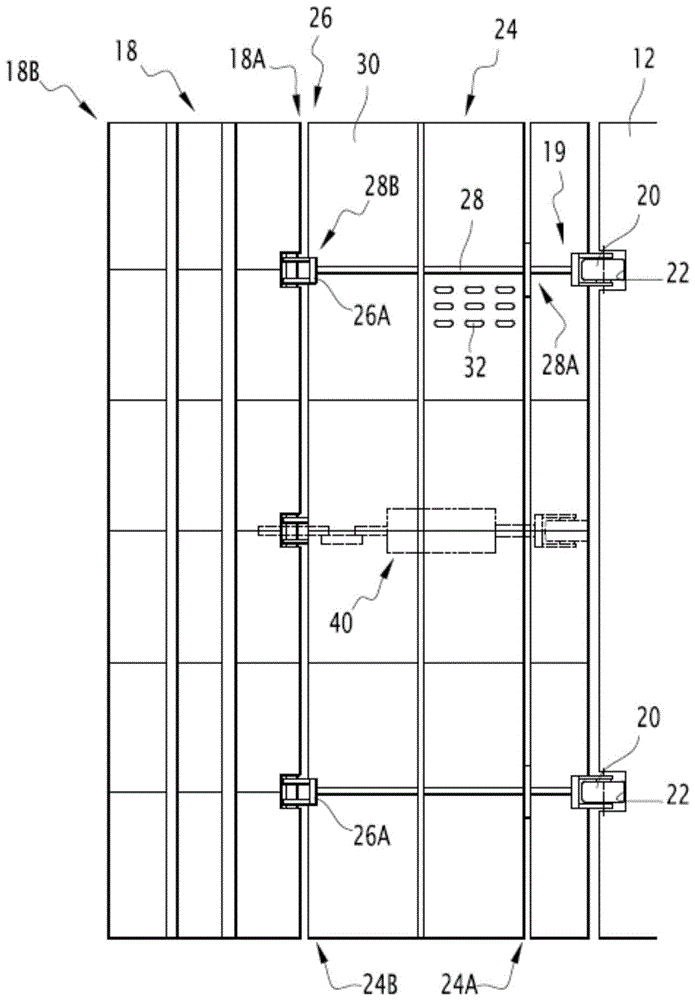

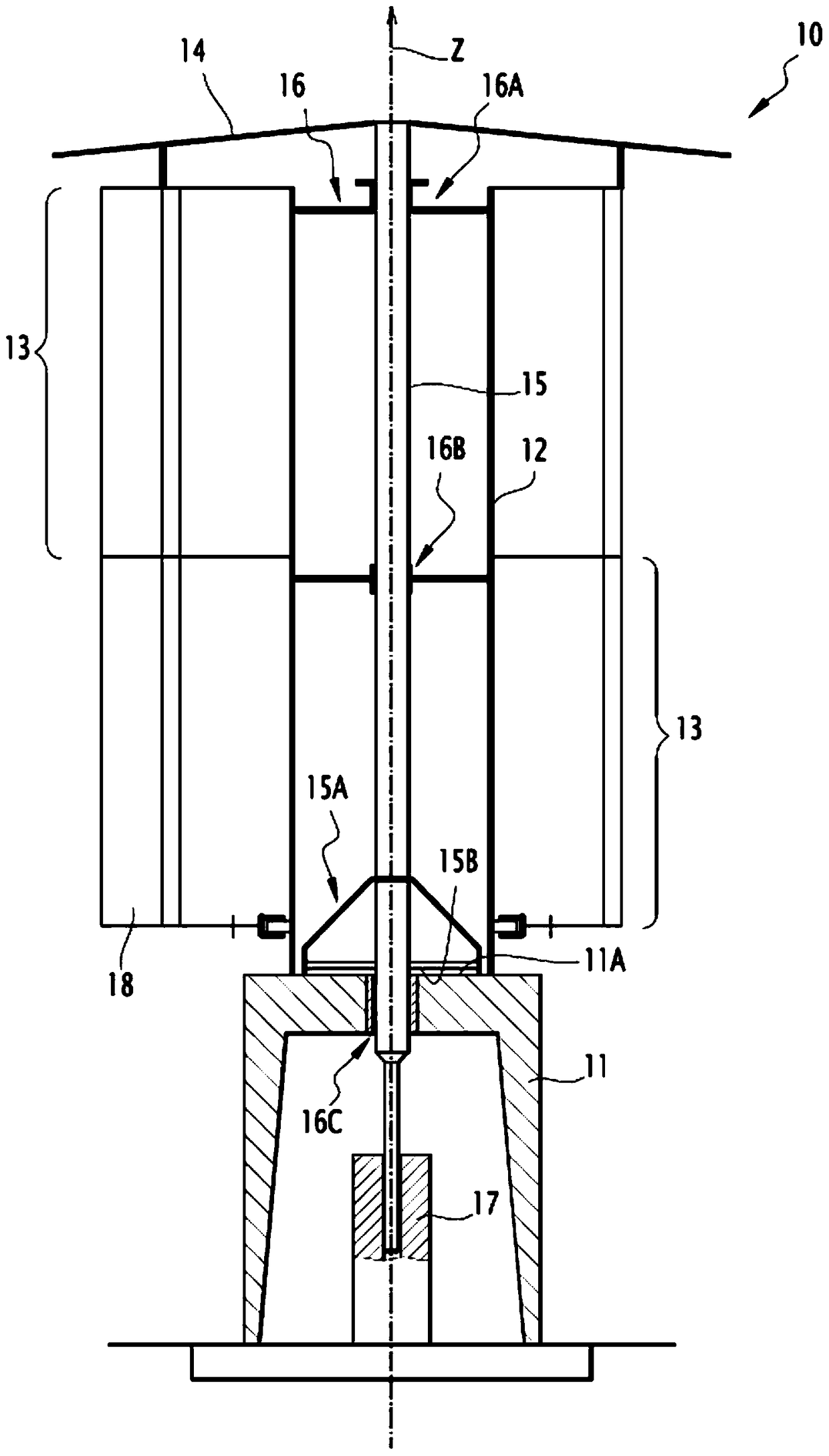

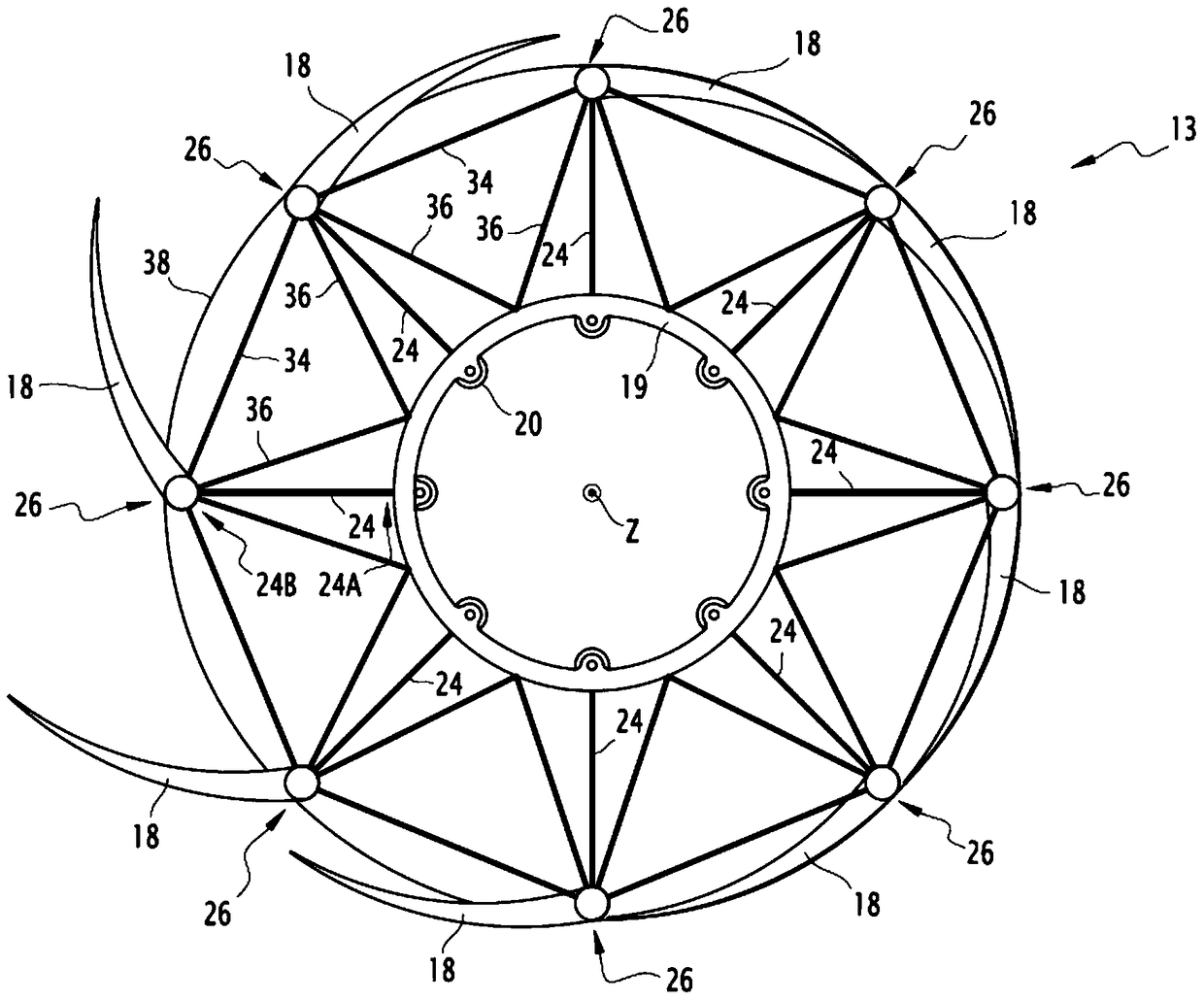

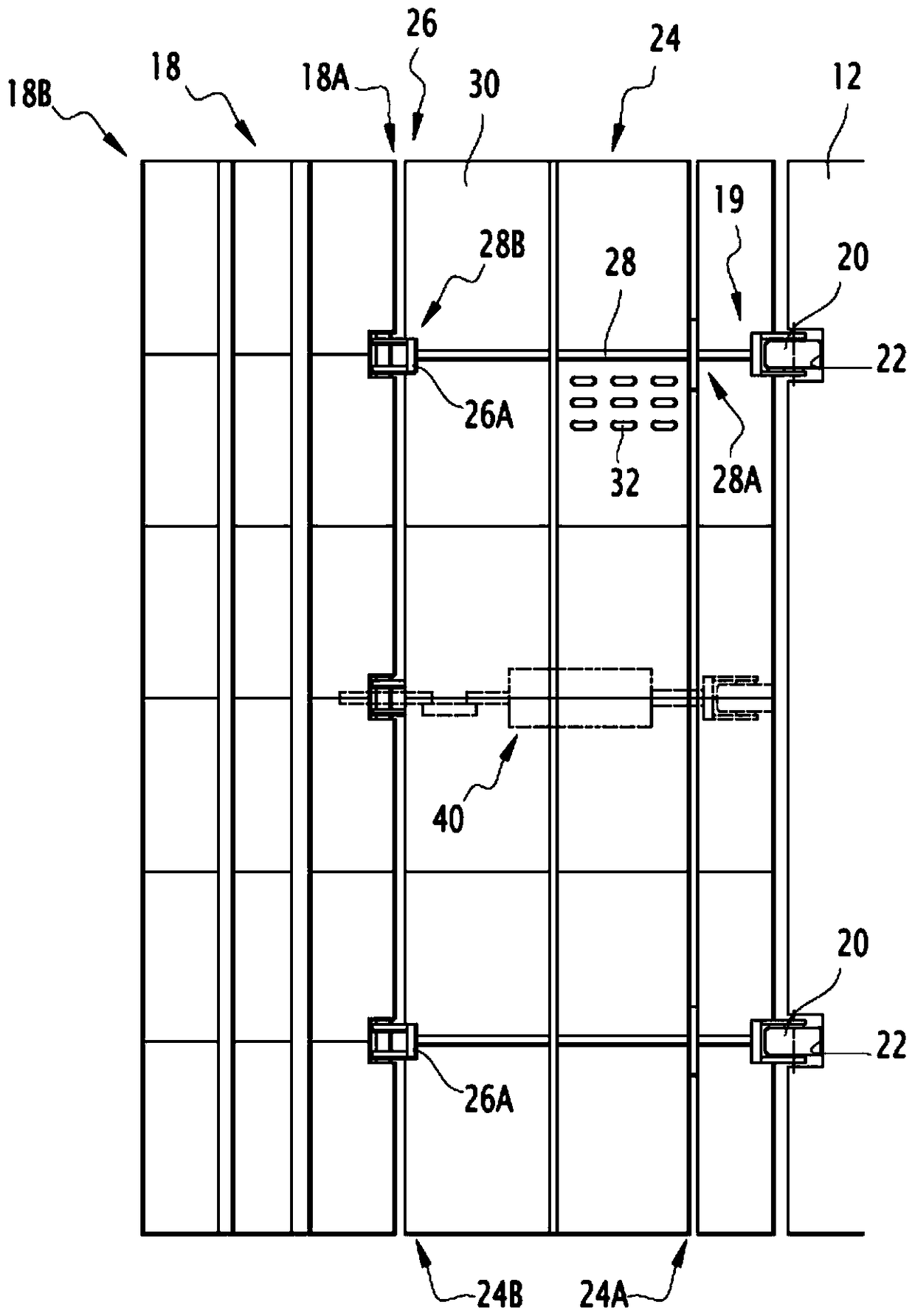

ActiveCN104995401AHigh outputBlocking smallWind motor controlEngine fuctionsDrive shaftMechanical energy

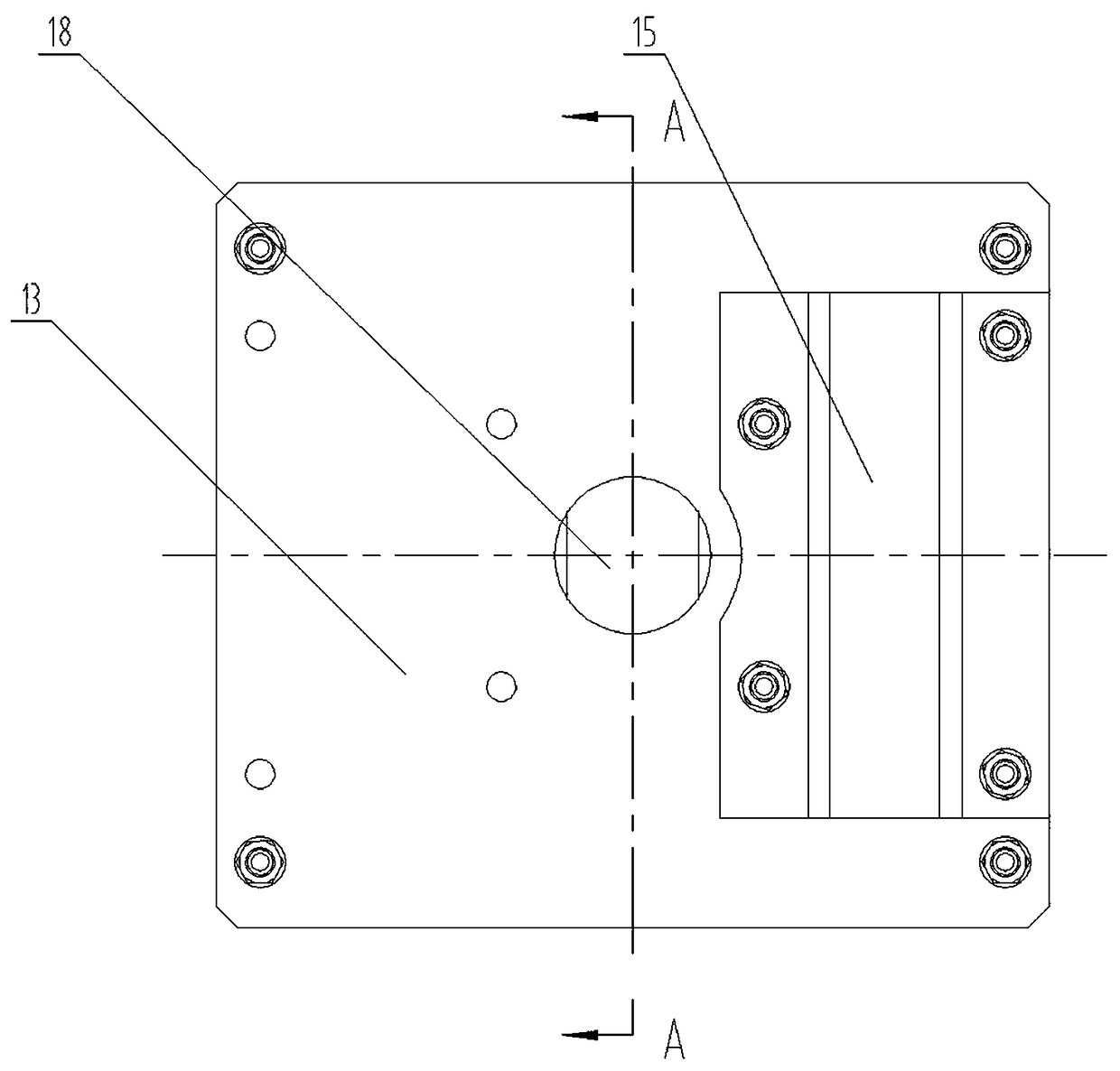

The device (10) comprises a base (11), a hollow mast (12) mounted on the base (12) along a vertical axis (Z), and at least one module (13) able to rotate about the mast (12). Said module (13) comprises at least one flap (18) that can be moved about a pivot connection (26) between a retracted position and a deployed position, and means (40) for moving the flap (18) between its deployed and retracted positions according to the angular position of this flap (18) about the mast (12). A shaft (15) positioned inside the hollow mast (12) rotates as one with this module (13) and collaborates with a converter (17) that converts the mechanical energy of rotation of the shaft (15) into said mechanical or electrical energy.

Owner:PANIPA

Guideway

InactiveCN101454508ASmooth and comfortable operationReliable Oscillation DampingRailway tracksElectrical and Electronics engineeringMagnetic levitation

Owner:MAX BOGL BAUUNTERNEHMUNG

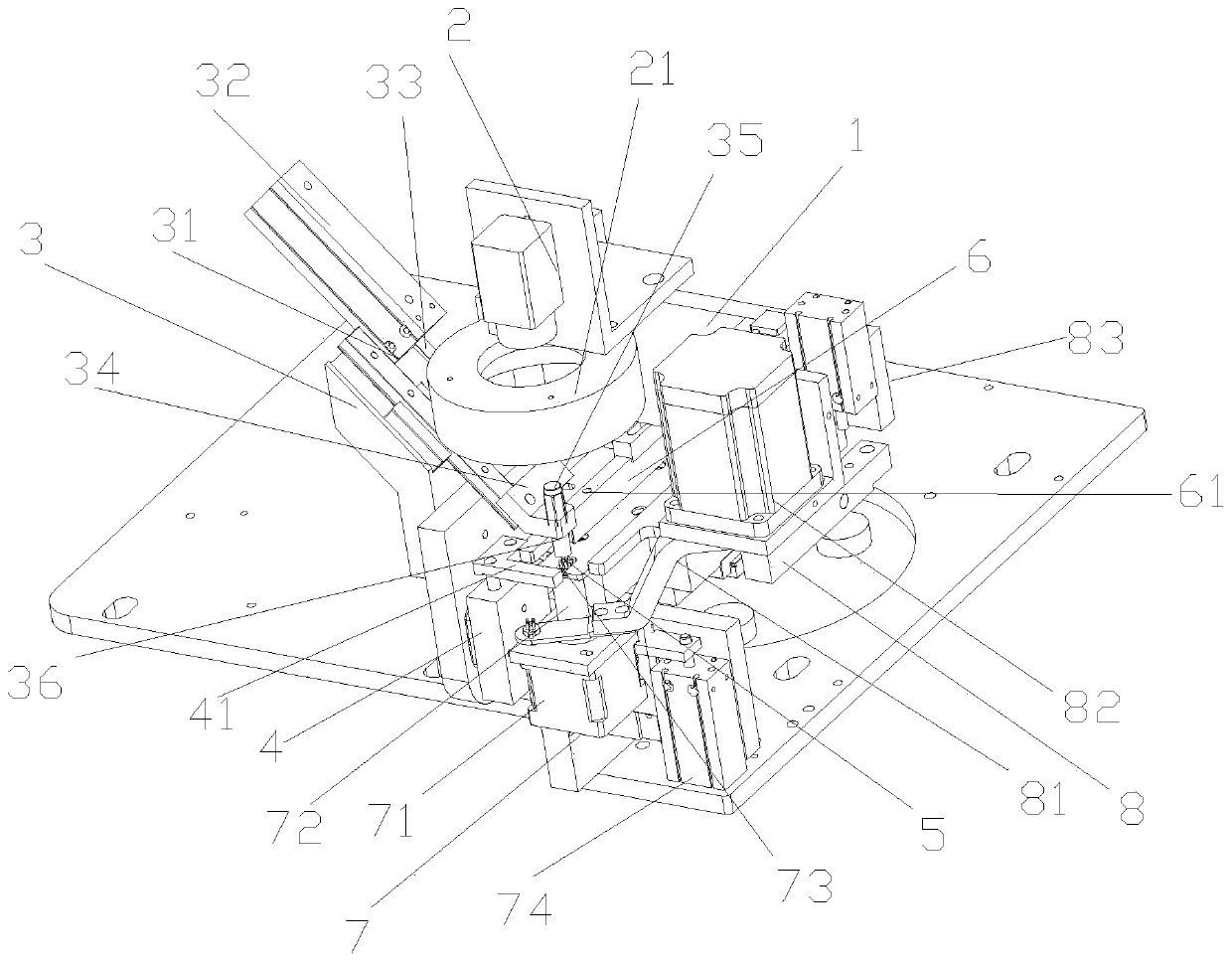

Automatic button conveying device with button recognizing and adjusting function

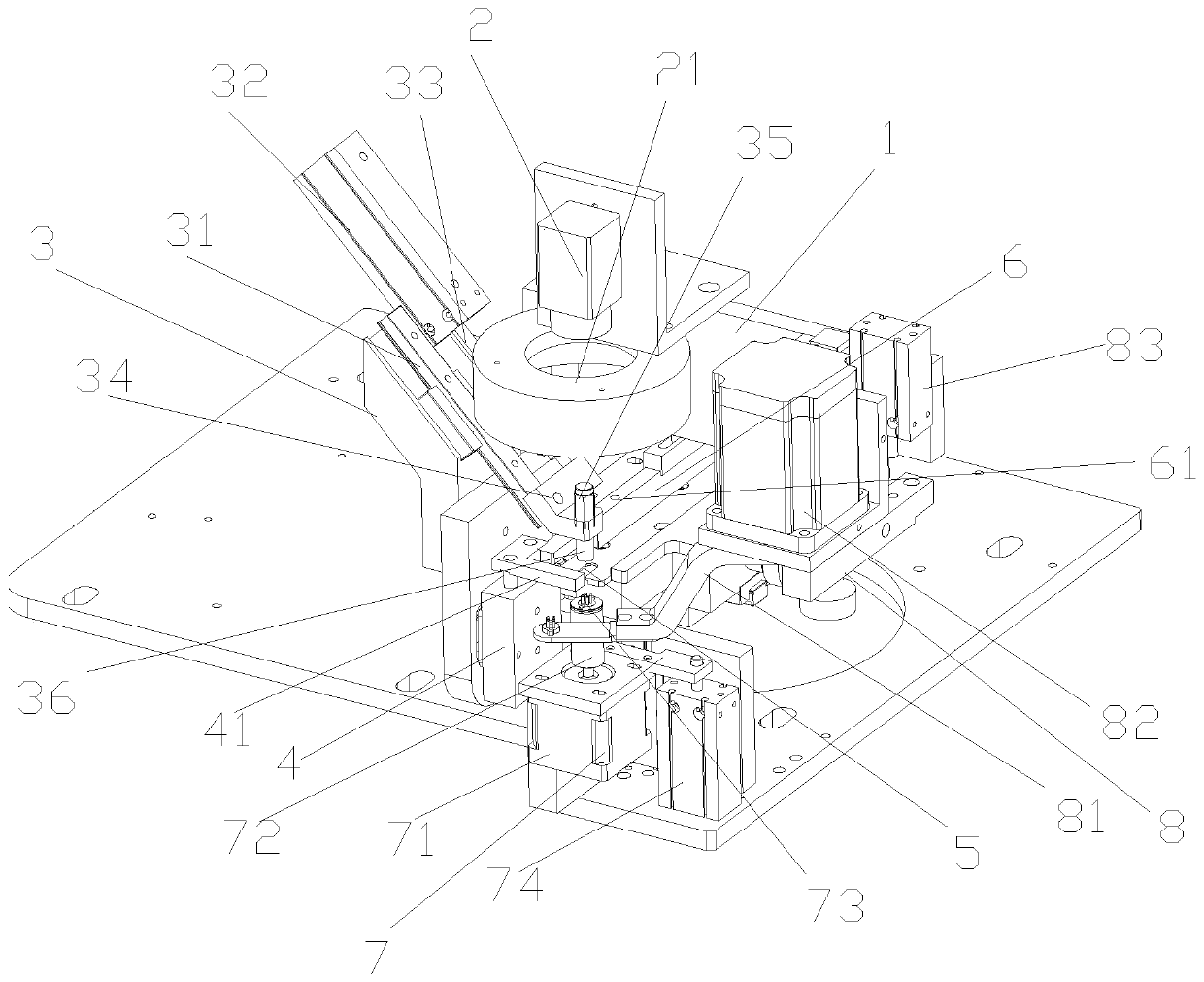

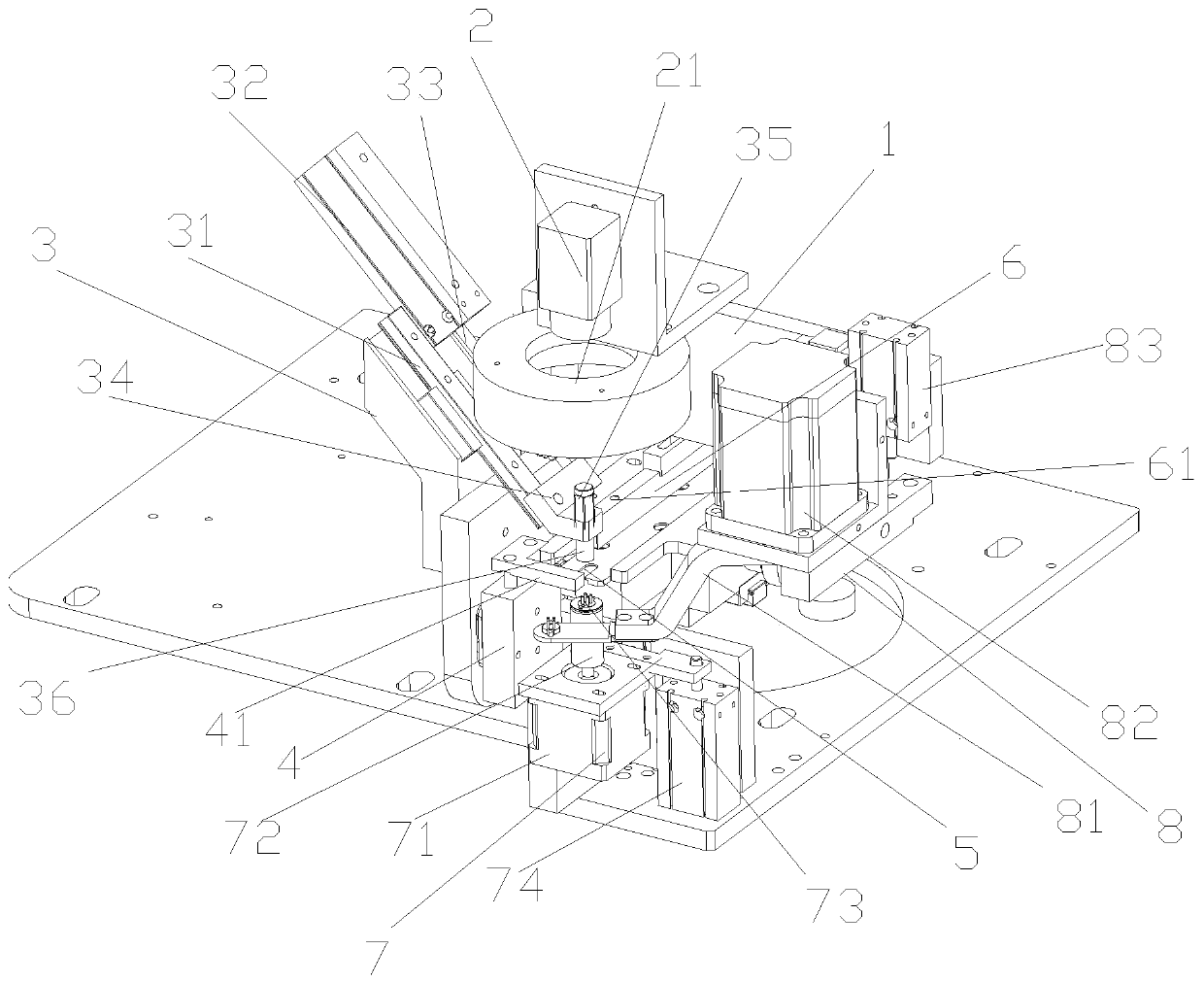

The invention provides an automatic button conveying device with a button recognizing and adjusting function. The automatic button conveying device is provided with an image acquisition device for acquiring button surface pattern at a button discharging opening position, a button pressing device which moves through a sliding rail is arranged above the button discharging opening of the automatic buttoning conveying device, a buttoning adjusting device used for adjusting the button direction at the button discharging opening is further arranged on the automatic buttoning conveying device, a through hole with an opening is formed in the side surface of the buttoning discharging opening of the automatic button conveying device, and the image acquisition device transmits acquired button surfaceimage information to a control system of the automatic button conveying device; the control system has a button direction recognition function, can be used for judging the actual direction of the button by comparing the acquired surface image information with pre-stored button image data, and can be used for sending a button adjusting instruction to the button adjusting device; and the button adjusting device is used for adjusting the direction of the button according to the button adjusting instruction. The automatic button conveying device has the advantages that whether the pattern of thebutton needs to be adjusted or not is determined according to the shape of the button pattern which is shot by the control system, and the pattern orientation of the buttons when the buttons are nailed can be unified.

Owner:周全超

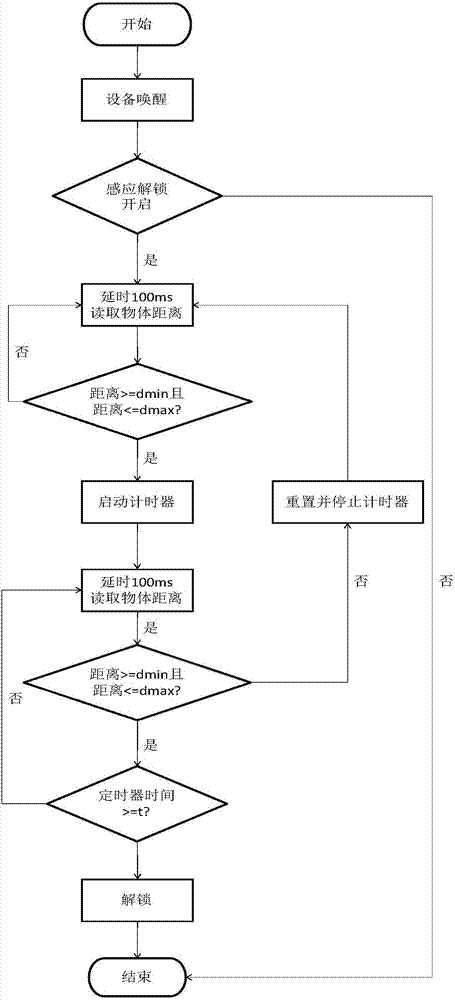

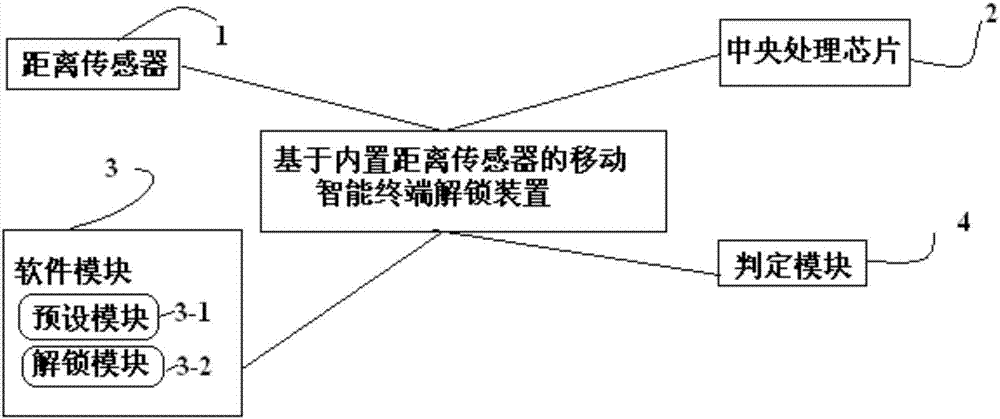

Mobile terminal unlocking method and apparatus based on built-in distance sensor

InactiveCN107295176AWill not interfere with operationEnsure safetySubstation equipmentEmbedded systemSpecific time

The invention provides a mobile terminal unlocking method based on a built-in distance sensor. The mobile terminal unlocking method based on a built-in distance sensor includes the steps: 1) a distance sensor is arranged in a mobile smart terminal device; 2) a user moves a shielding object overhead the sensor, and obtains the distance data of the shielding object through the distance sensor; 3) the distance sensor is connected with a central processing chip in the mobile smart terminal device, and the central processing chip is used for obtaining the data of the distance sensor; 4) the central processing chip uploads the obtained data to special software to perform noise reduction, and obtains the practical distance of the shielding object through conversion; and 5) if the practical distance is determined to be maintained beyond a special time, the device can be unlocked. The invention also provides a mobile terminal unlocking apparatus based on a built-in distance sensor. The mobile terminal unlocking apparatus based on a built-in distance sensor is more convenient on the premise of guaranteeing safety, and uses the distance sensor contained in the device, thus saving the cost and being more mature in technology.

Owner:SHENZHEN JING ZHOU TECH CO LTD

Luggage case with hidden table and chair

InactiveCN107713232AWill not interfere with operationIncrease storage spaceLuggageOther accessoriesEngineeringMechanical engineering

Owner:广西景康商贸有限公司

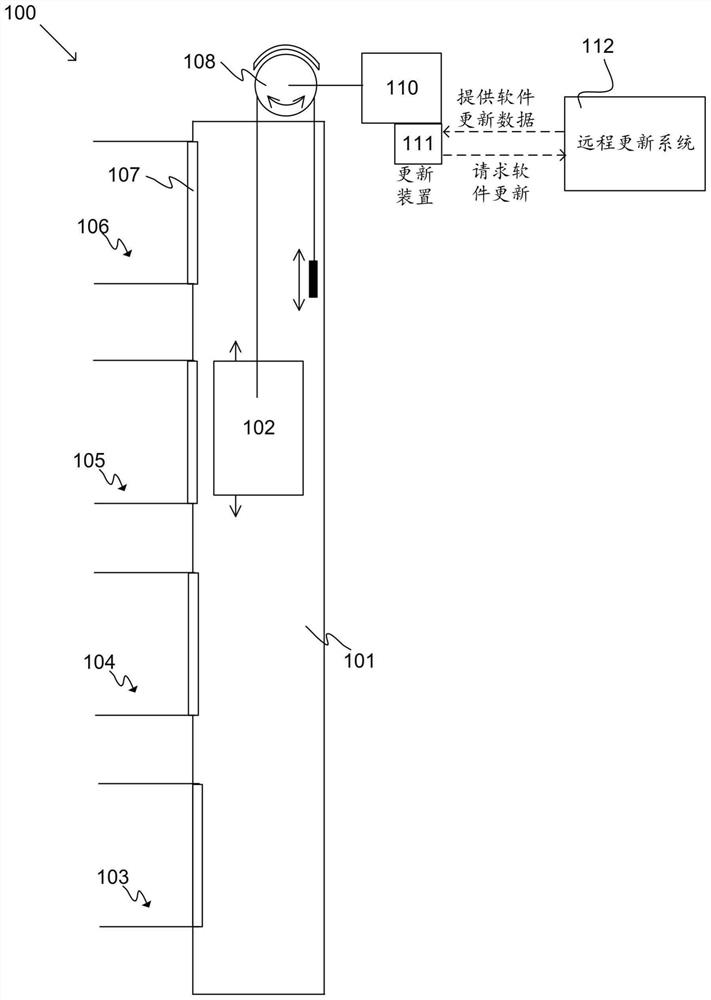

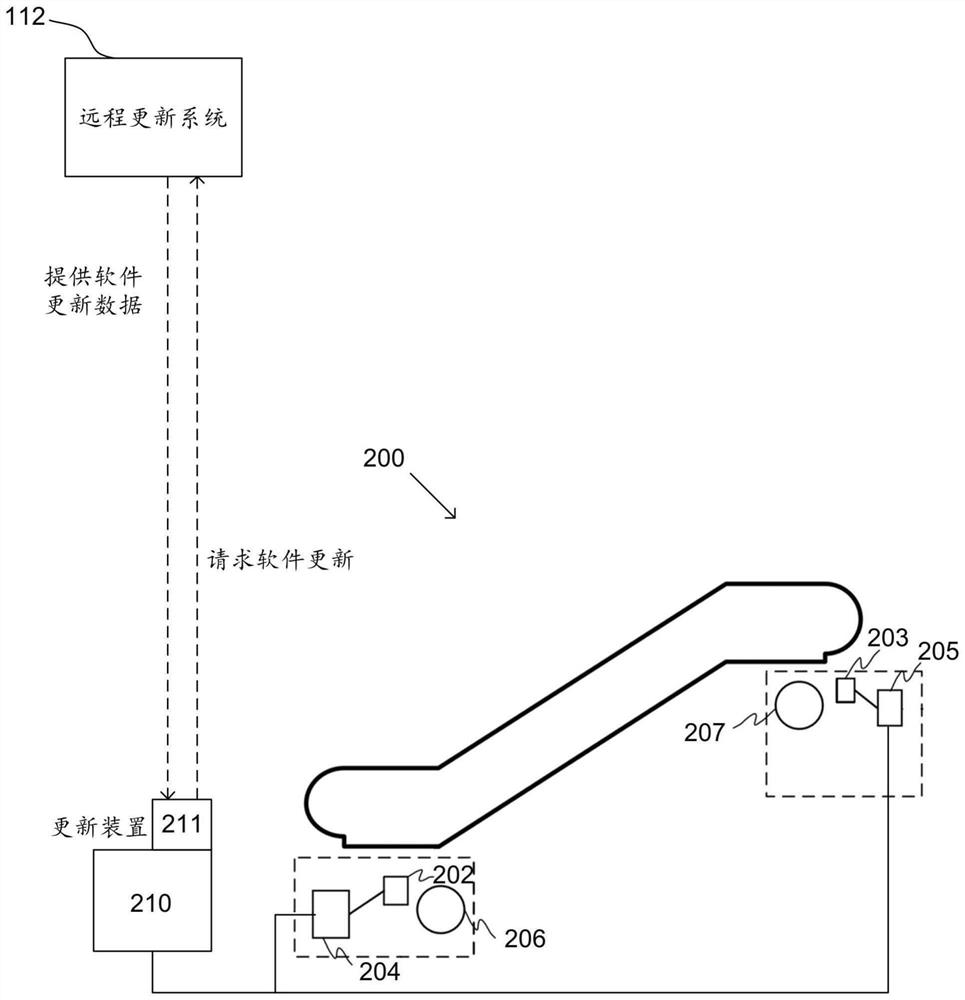

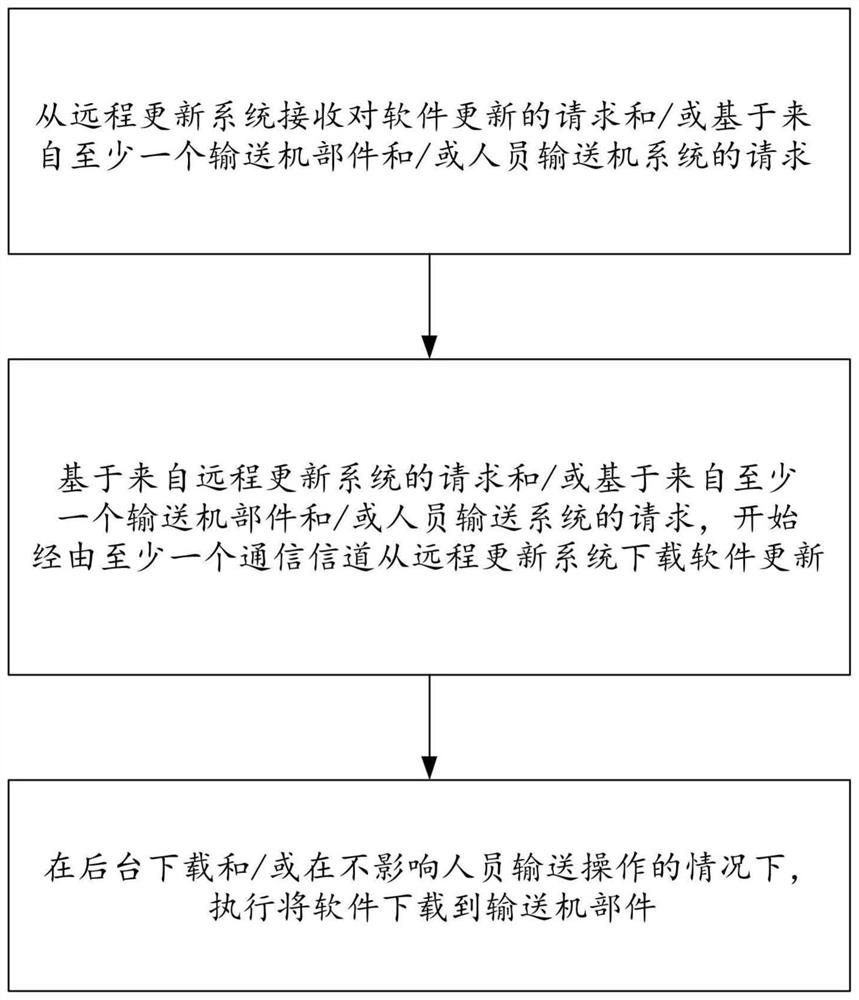

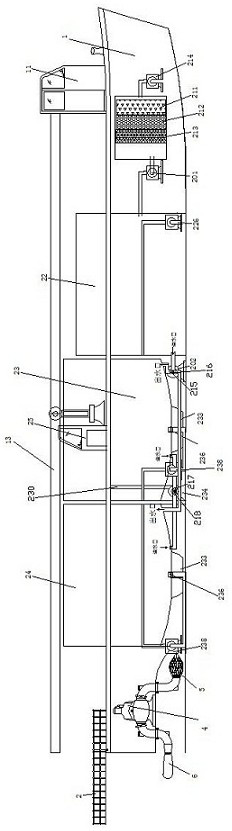

People conveyor system and method for updating software of people conveyor component

PendingCN113734922AWill not interfere with operationUpdates are automatic and reliableVersion controlDigital data protectionElevator systemSoftware update

A people conveyor system and a method for software update of a people conveyor component in a people conveyor system, such as an elevator system (100), an escalator system (200) and / or a moving walkway system. The conveyor system comprises a plurality of conveyor components, each said conveyor component comprising a memory and a processor running an application software, an updating means (111, 211)for updating conveyor component software, the updating means being communicatively connected to the conveyor components, wherein the updating means comprises or is connected to a processor and a memory, and at least one communication channel, arranged between the updating means (111, 211) and a remote update system (112). In the method the updating means (111, 211) downloads a software update from the remote update system (112) via the at least one communication channel based on request from the remote update system (112) and / or based on the request from at least one conveyor component and / or the people conveyor system, and wherein the software download to the conveyor component is performed as a background download and / or without affecting the operation of the people conveyor.

Owner:KONE CORP

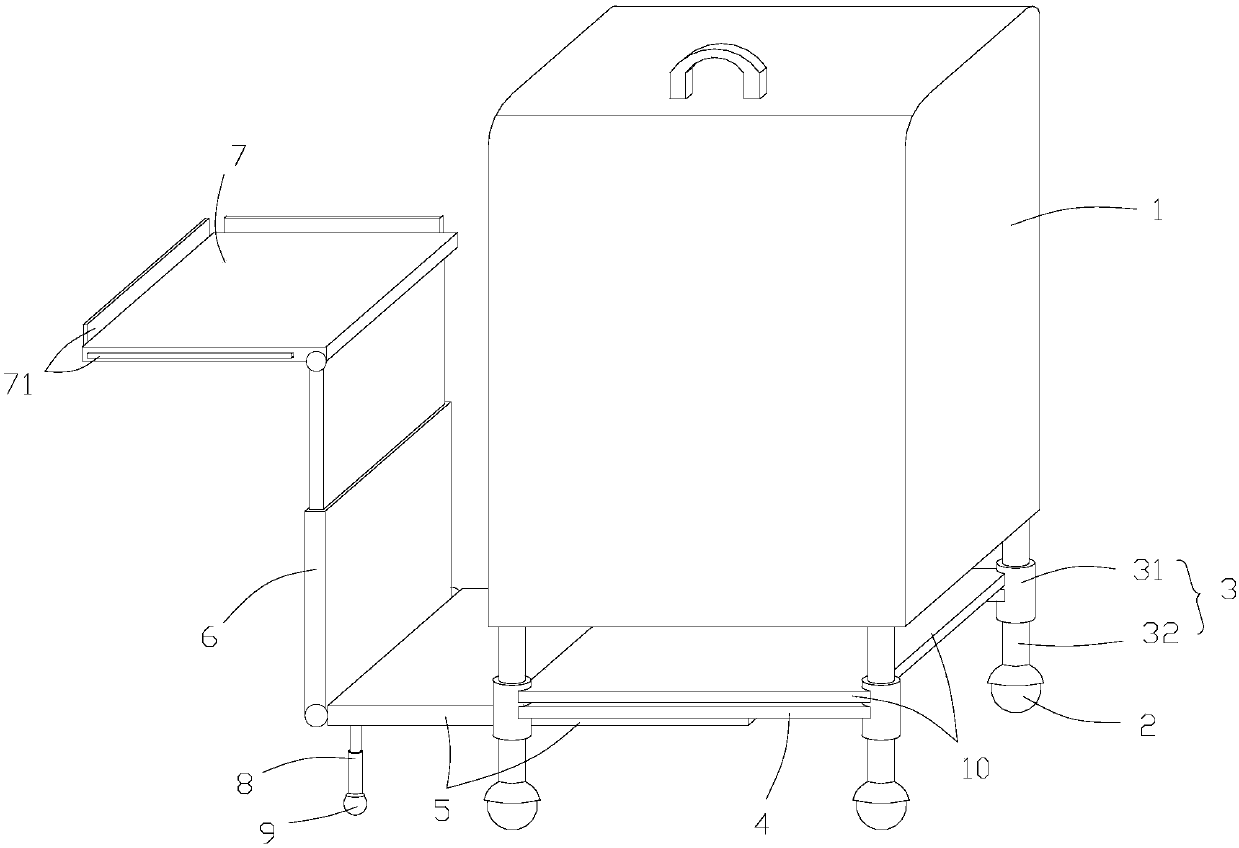

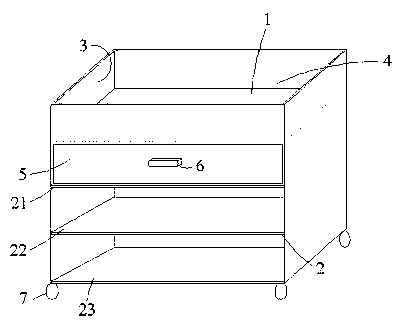

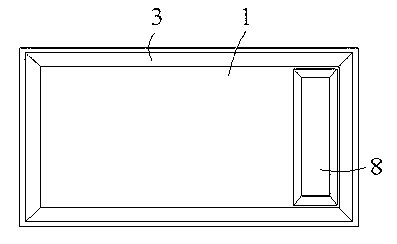

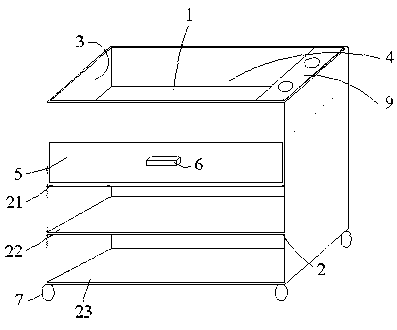

Article holding trolley for interventional therapy

InactiveCN103284800AEasy accessWon't fallSurgical furnitureDiagnosticsInterventional therapyInterventional treatment

The invention relates to an article holding trolley for interventional therapy. The article holding trolley comprises a top plate and at least two layers of article holding plates sequentially from top to bottom, stop plates are arranged around the top plate, a top groove is formed on the top plate, a holding groove recessed downwardly is arranged in the top groove, a drawer is arranged on at least one layer of article holding plate, a handle is arranged on the outer surface of each drawer, spaces among the article holding plates are open in front faces and back faces, and sliding wheels are arranged at the bottom of the article holding plate on the bottommost layer. By the article holding trolley, medical supplies required by the interventional therapy can be placed uniformly, conditions for orderly working are provided for medical workers, improvement of working efficiency is facilitated, and the article holding trolley can be moved optionally and cannot interfere with other operations of the medical workers.

Owner:太仓市第一人民医院

Four-roller hydraulic transmission plate bending machine

InactiveCN112935032AReduce frictionWill not interfere with operationMetal-working feeding devicesShaping safety devicesMachineScrew thread

The invention discloses a four-roller hydraulic transmission plate bending machine which comprises a plate bending machine body. A cavity is formed in one side of the plate bending machine body, and a first groove is formed in one side of the interior of the cavity; a second rotating shaft is arranged in the first groove, and a supporting rod is hinged to one side of the second rotating shaft; a sliding groove is formed in the position, close to the center, in the supporting rod; a threaded hole is formed in the right end of the supporting rod, and a threaded rod is in threaded connection with the interior of the threaded hole; a sliding block is slidably connected with the interior of the sliding groove, and the end, away from the interior of the sliding groove, of the sliding block is fixed to one end of a connecting rod; and fixed clamping plates are fixed to the other end of the connecting rod, and a pulley is installed between the fixed clamping plates. According to the bending machine, a plate can be effectively supported, and meanwhile the supporting position can be adjusted according to the size of the plate; therefore, the applicability of the machine is improved, and in addition, the pulley is rotated to clean the surface of the plate; and the stress of the plate is improved, and the product quality is improved.

Owner:许攀

Circuit comprising a capacitor and at least one semiconductor component, and method for designing same

InactiveCN100440506CWill not interfere with operationSame protective effectSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsEngineering

Owner:圣微电子股份有限公司

Laser energy supply device

InactiveCN101399465BHigh cost ratioLow costElectromagnetic wave systemCircuit arrangementsComputer moduleEnergy supply

The invention provides a laser energy-supplying device. The device comprises a laser module and a light splitting module; the laser module is connected with the input terminal of the light splitting module by optical fiber. After the laser module outputs laser to the light splitting module, the light splitting module divides the laser into three bunches and transfers the laser to A-phase equipment, B-phase equipment and C-phase equipment respectively. The device can satisfy the requirements of power supply of three-phase load, cost is low, reliability is good, and maintenance is easy.

Owner:WUHAN YANGTZE OPTICAL NETWORK COMM CO LTD

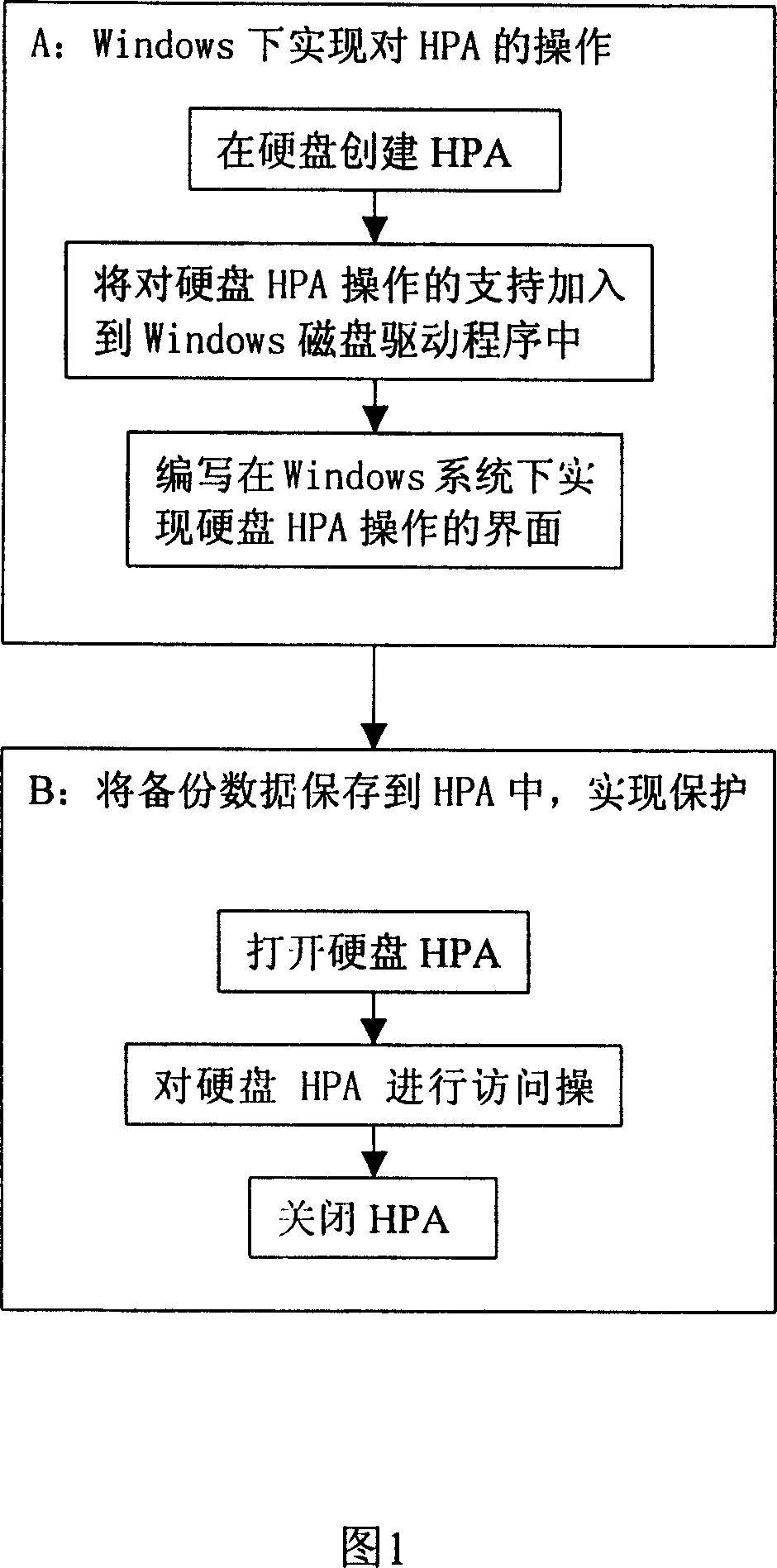

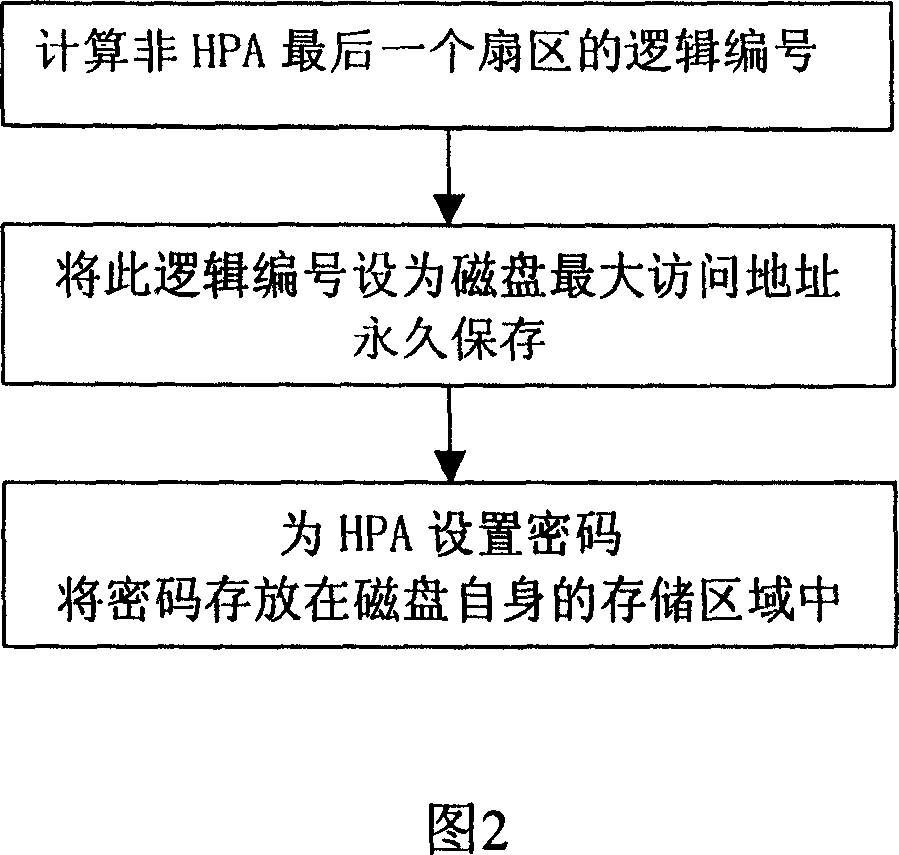

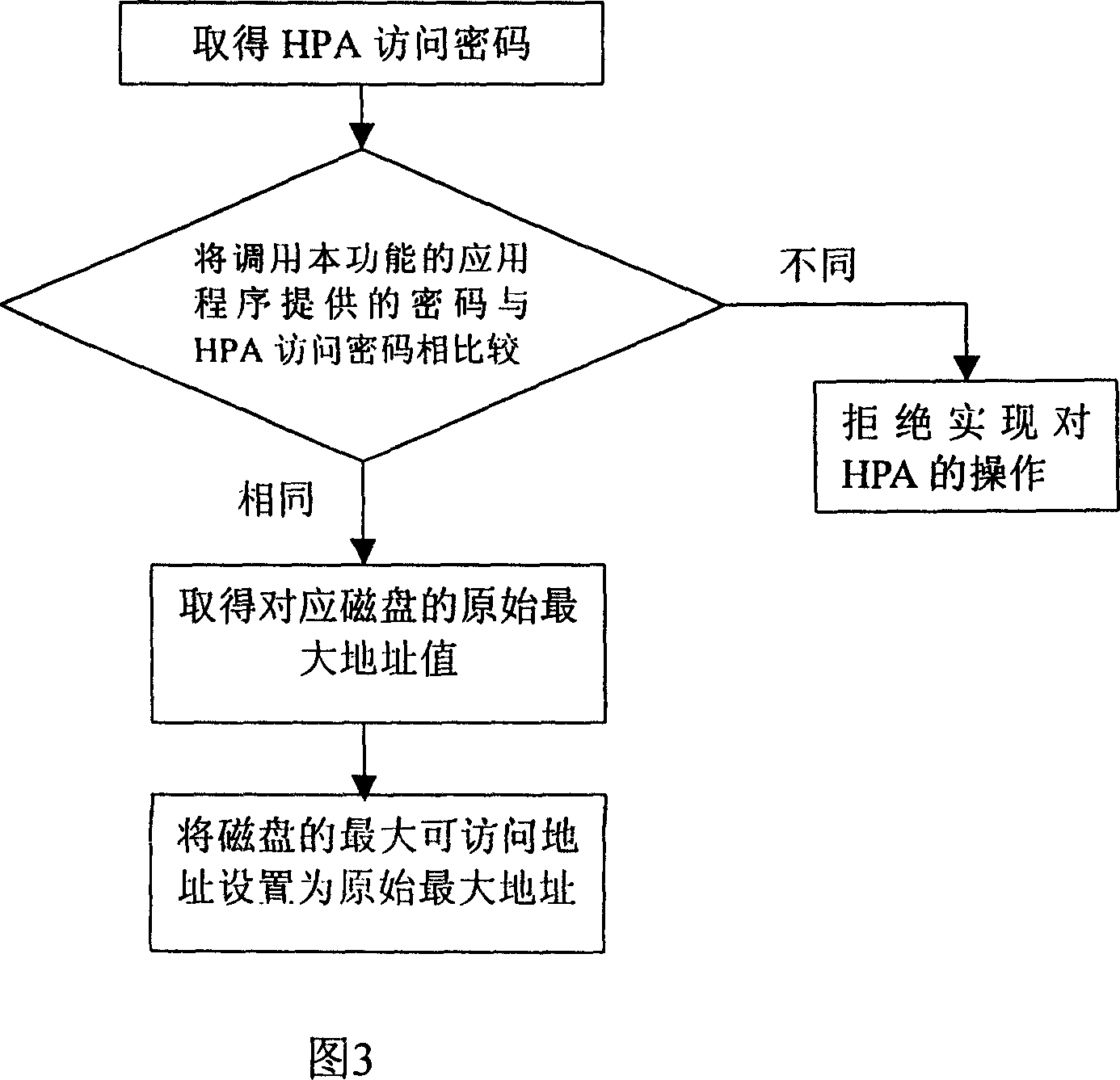

Method of utilizing hidden hard disc sector in protecting data under Windows system

InactiveCN1308845CImprove securityAvoid breakingMemory loss protectionUnauthorized memory use protectionComputer hardwareComputer science

The present invention provides method of utilizing hidden hard disc sector in protecting data under Windows system and belongs to the field of computer safety technology. The implementation includes the following steps: the step A of operation on hard disc HPA under Windows system including creating HPA in the hard disc, adding the back-up to hard disc HPA operation to Windows disc driving program, and creating interface for realizing hard disc HPA operation in Windows system; and the step B of saving the back-up data in HPA of hard disc for protection via the features of PHA via opening hard disc HPA, accessing hard disc HPA to protect back-up data, and shutting HPA. The method has the advantages of high safety, convenient operation, low cost, etc.

Owner:LENOVO (BEIJING) LTD

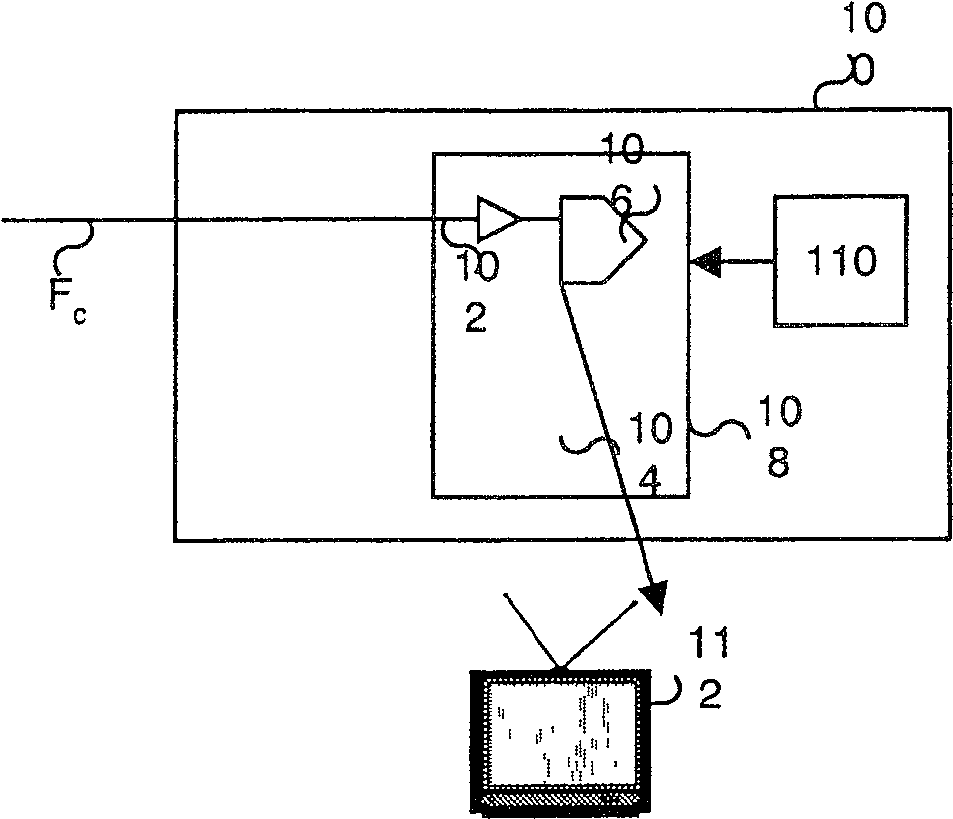

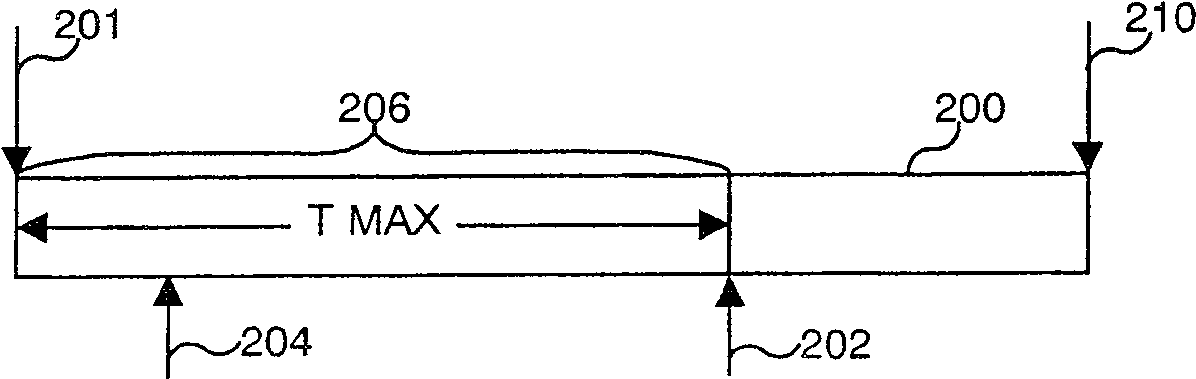

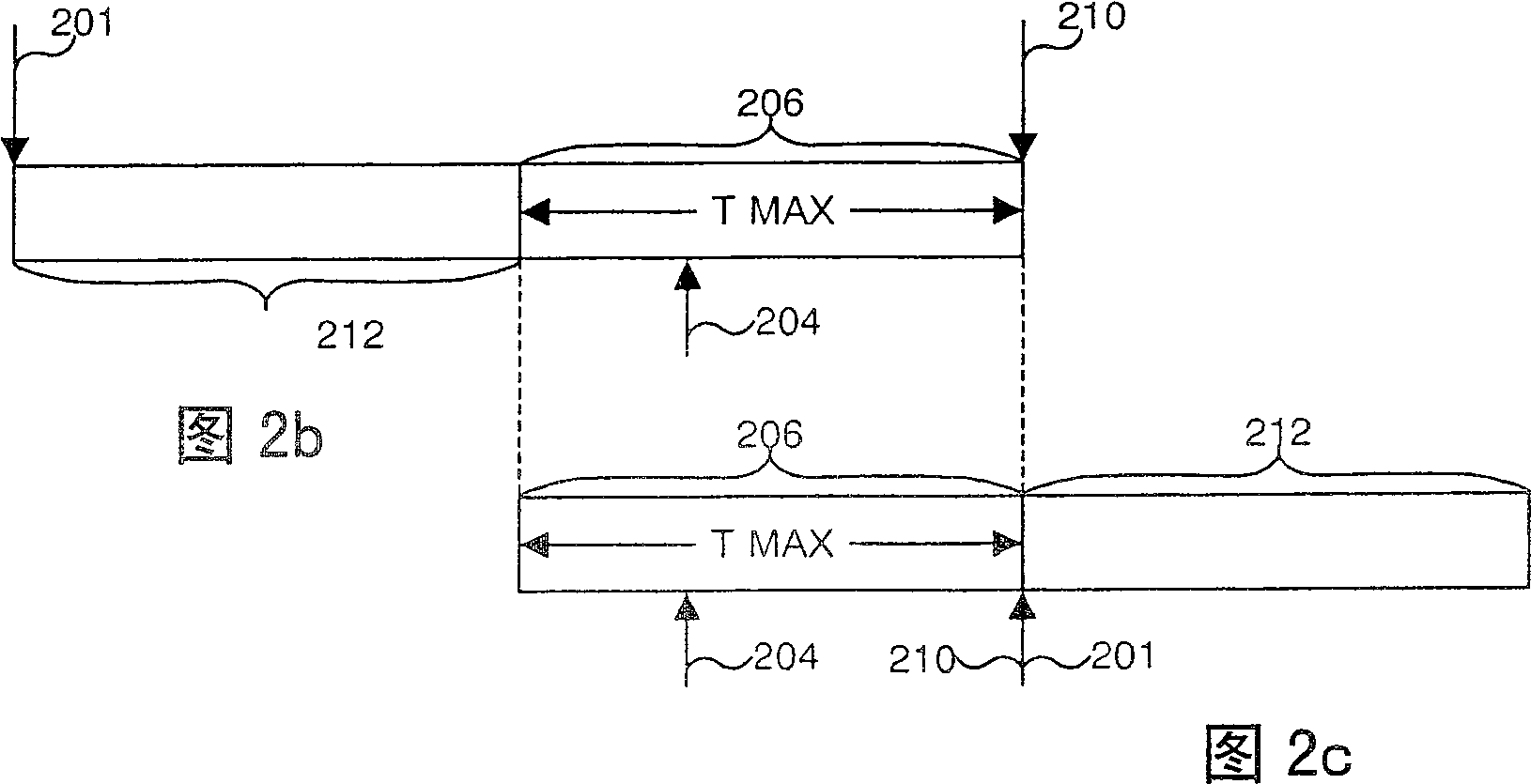

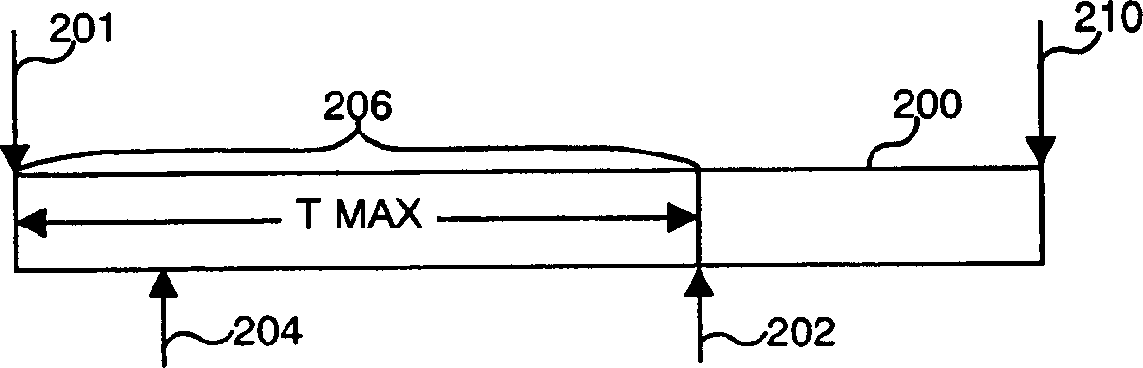

Device and method for delayed reading of digital video data

InactiveCN100508575CControl the amount of resourcesWill not interfere with operationTelevision system detailsColor television detailsDigital videoPresent method

The invention relates to a method of delayed reading digital video data stored in a file (200) on a recording medium (108). According to the method, a fixed amount of storage resources of a recording medium (108) is allocated to files (200) storing these data. Applied to the digital decoder.

Owner:INTERDIGITAL CE PATENT HLDG

Device and method for delayed reading of digital video data

InactiveCN1672407AControl the amount of resourcesWill not interfere with operationTelevision system detailsColor television detailsDigital videoData storing

Owner:INTERDIGITAL CE PATENT HLDG

Foldable scrubbing type filter cloth cleaning device

InactiveCN112791466AWill not interfere with operationEasy to cleanFiltration separationFilter pressControl theory

The invention discloses a foldable scrubbing type filter cloth cleaning device, and belongs to the technical field of filter cloth cleaning equipment of filter presses. The device comprises: a portal frame; a sliding seat; a spraying head which comprises a transverse pipe and a vertical pipe which are vertically connected; a rotating mechanism which is used for driving the transverse pipe to rotate around the X-axis direction, wherein the rotating mechanism comprises at least one rotating arm; and a linear telescoping mechanism. According to the foldable scrubbing type filter cloth cleaning device, only the vertical pipe needs to be folded to the position above the filter plate through rotation, the vertical pipe does not need to be lifted in the vertical direction, the height of the needed portal frame is greatly reduced, the height of the whole cleaning device is reduced, and the installation occupied space of the cleaning device is reduced. Moreover, when the brush is arranged around the water nozzle, the brush can also brush the surface of the filter cloth in the process that the water nozzle movably sprays water to the filter cloth, so that the comprehensive cleaning effect on the filter cloth is improved.

Owner:ZHONGDA BRIGHT FILTER PRESS

A construction ship for the treatment of polluted rivers

ActiveCN109574414BWill not interfere with operationMeet the needs of waters of different depthsWater cleaningTreatment using aerobic processesDrive wheelElectric machinery

Owner:李兴元

vertical axis wind turbine

ActiveCN104995401BHigh outputBlocking smallWind motor controlEngine fuctionsDrive shaftVertical axis wind turbine

The device (10) according to the invention comprises a base (11), a hollow mast (12) mounted on the base (11) and extending along a vertical axis (Z), and at least one rotatable around the mast (12) module (13). Said module (13) comprises at least one flap (18) movable about a pivot link (26) between a retracted position and a deployed position, and according to said flap (18) around the mast (12) A mechanism (40) for moving the flap (18) between its deployed and retracted positions due to its angular position. The device also comprises a drive shaft (15), which is located inside the hollow mast (12), is rotatably connected to the module (13), and cooperates with a converter (17) to connect the drive shaft (15) ) into mechanical energy or electrical energy.

Owner:PANIPA

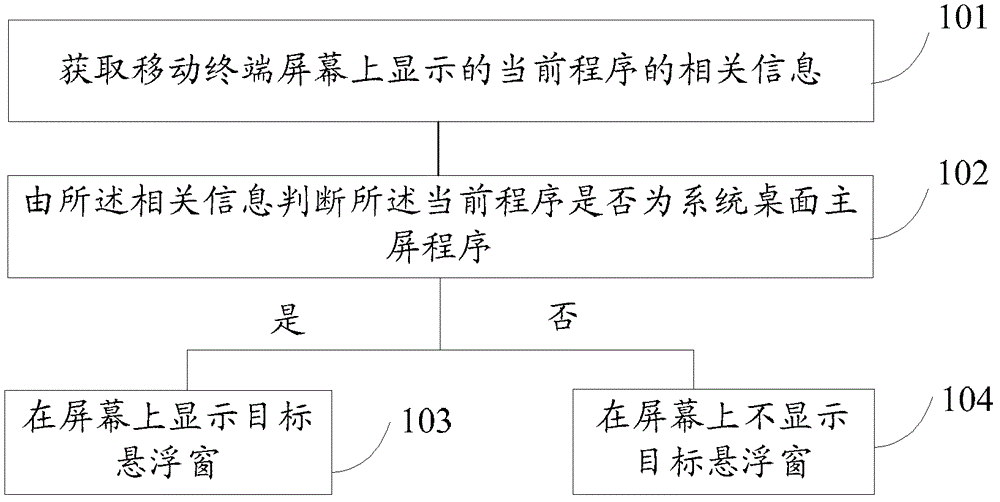

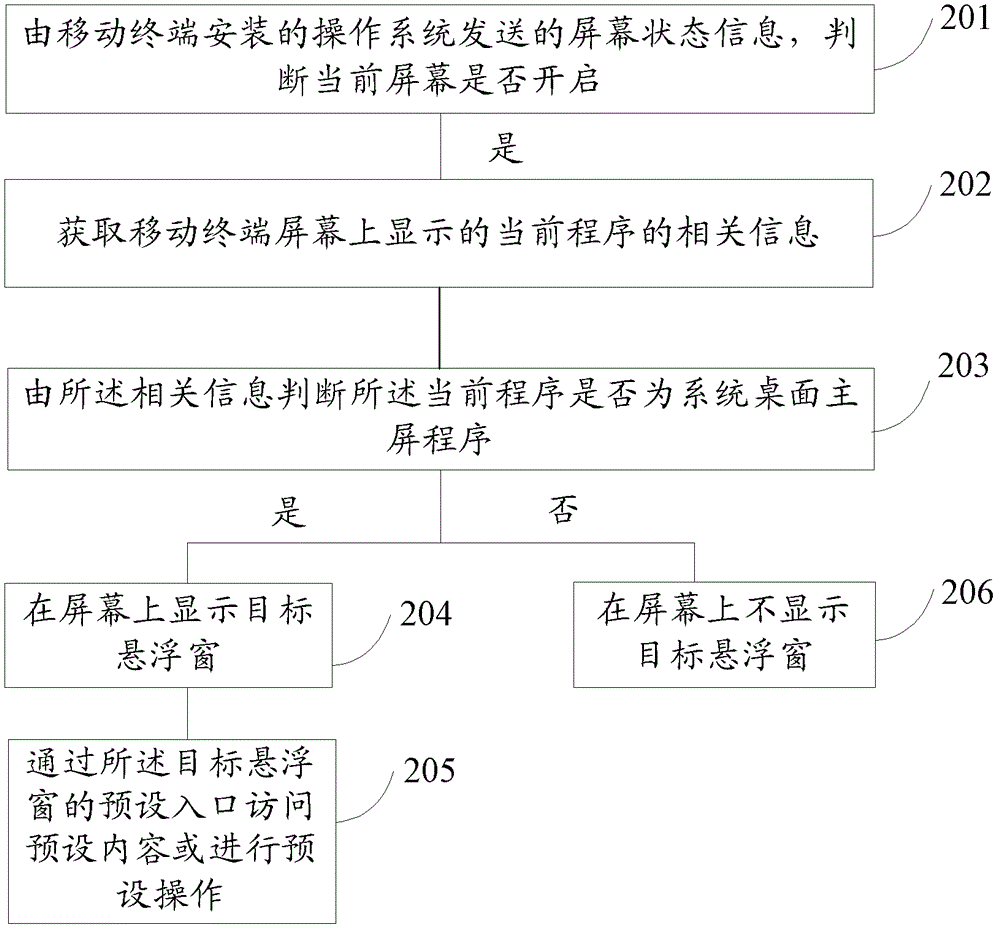

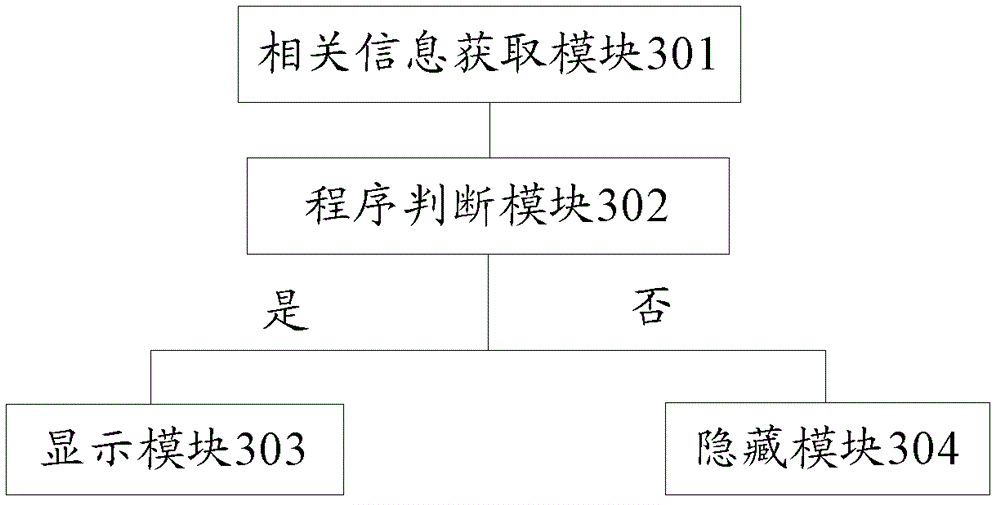

Method and device for displaying suspended window

ActiveCN102566931BWill not interfere with operationNo wasted electricitySpecific program execution arrangementsInput/output processes for data processingThird partyComputer terminal

The invention provides a method and device for displaying a suspended window. The method comprises the following steps: acquiring related information of a current program displayed on a mobile terminal screen; judging whether the current program is a main screen program of a system desktop according to the related information; if so, displaying a suspended window on the screen; and otherwise, displaying no suspended window on the screen. According to the invention, when a main screen program of a non-system desktop of a third party starts, the suspended window is automatically hidden, so that the suspended window does not disturb the operations of users.

Owner:BEIJING QIHOO TECH CO LTD

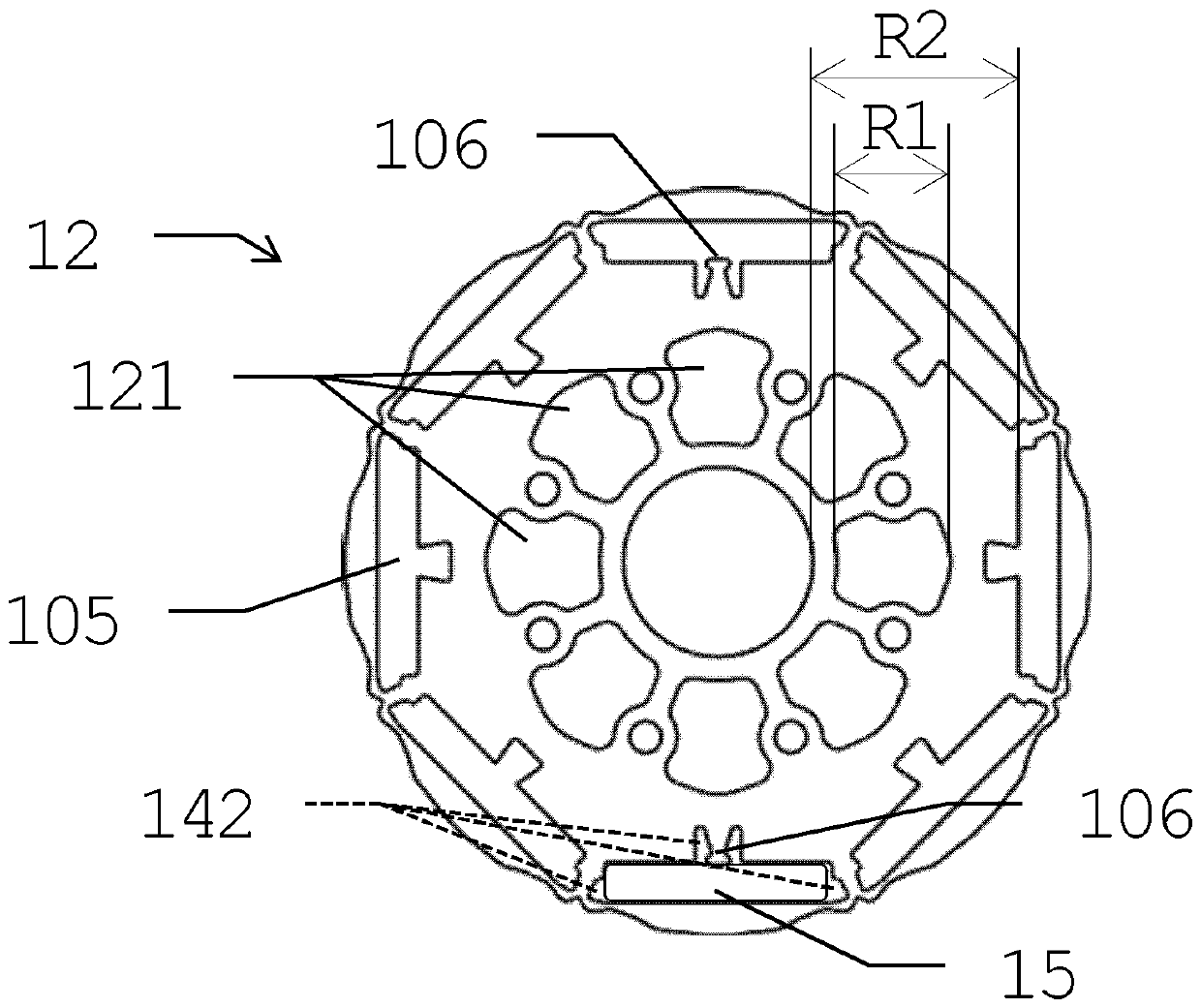

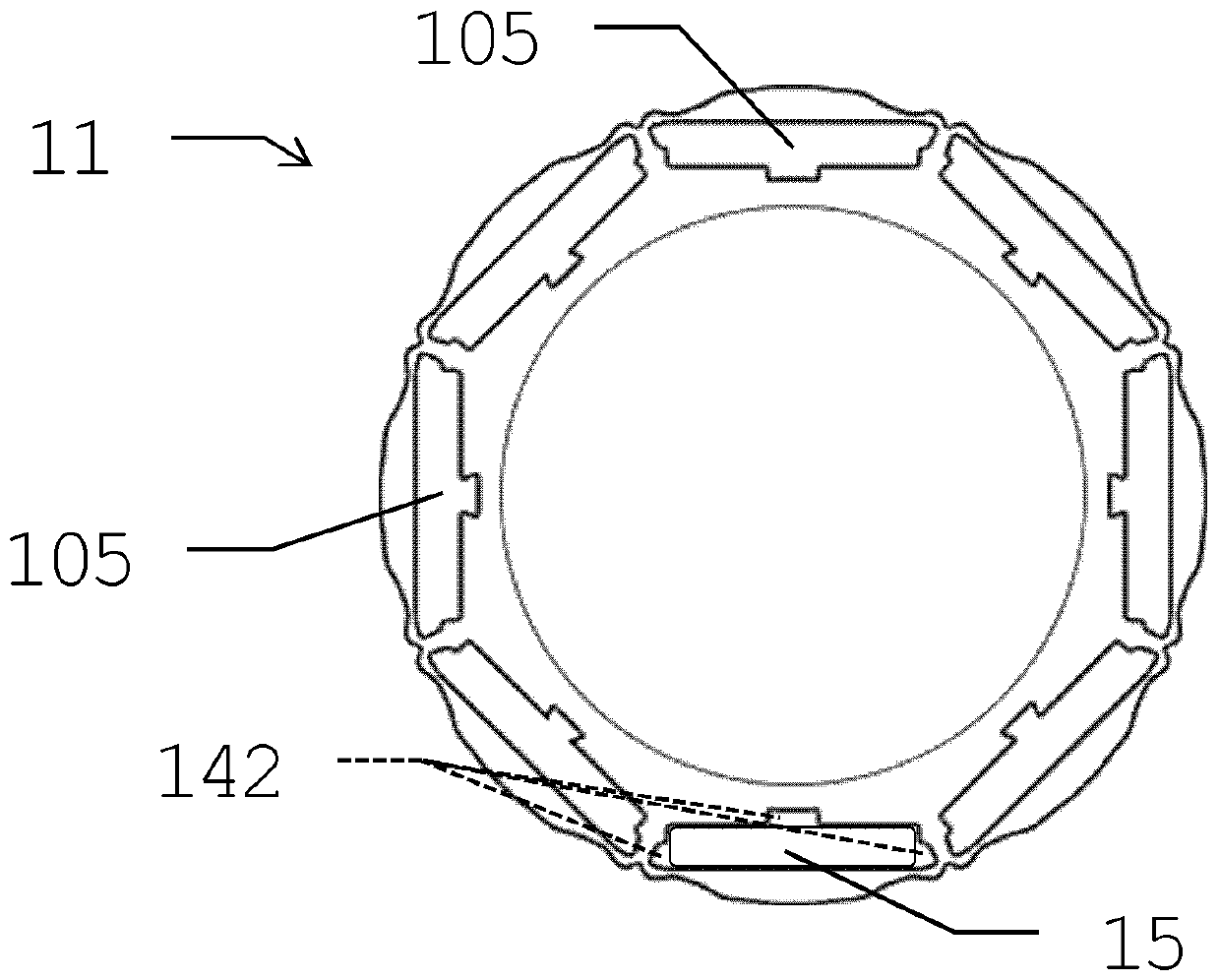

Motor and rotor thereof

PendingCN107872108ALight in massCompact layoutMagnetic circuit rotating partsSupports/enclosures/casingsEngineeringMechanical engineering

Owner:BOSCH AUTOMOTIVE PROD CHANGSHA

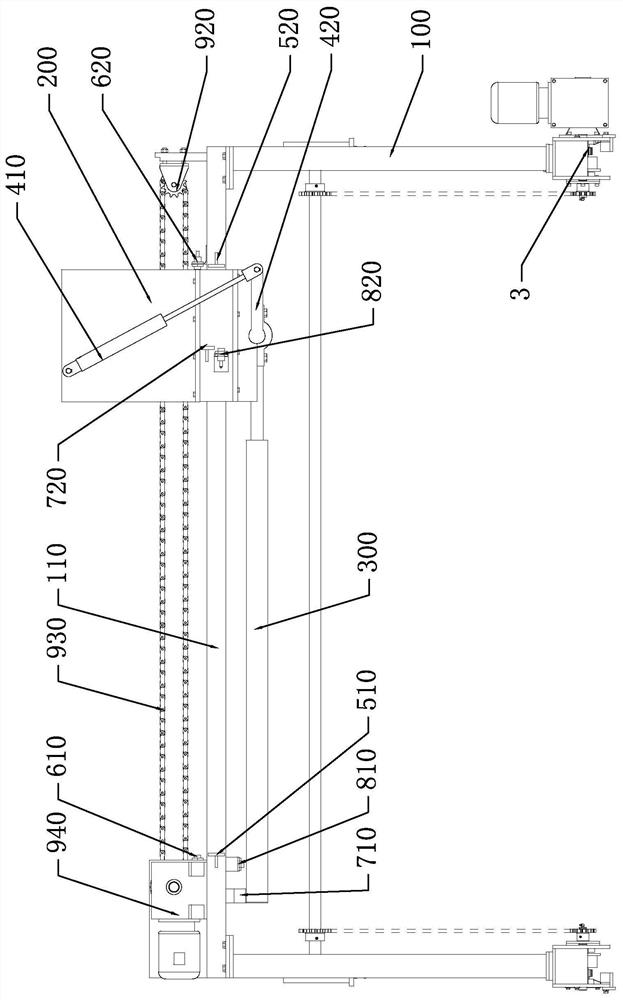

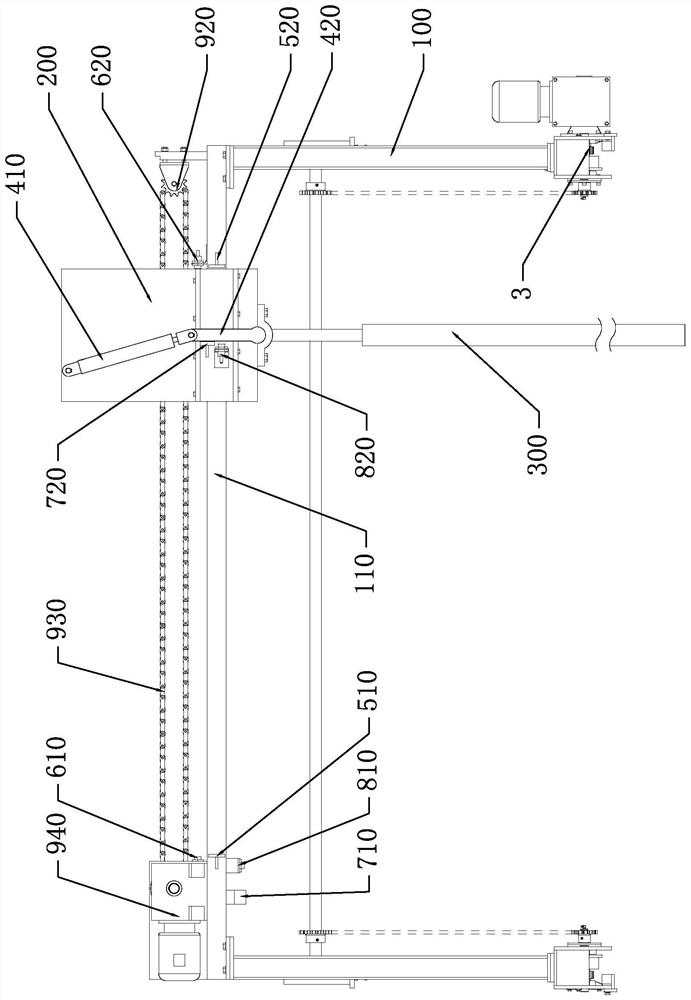

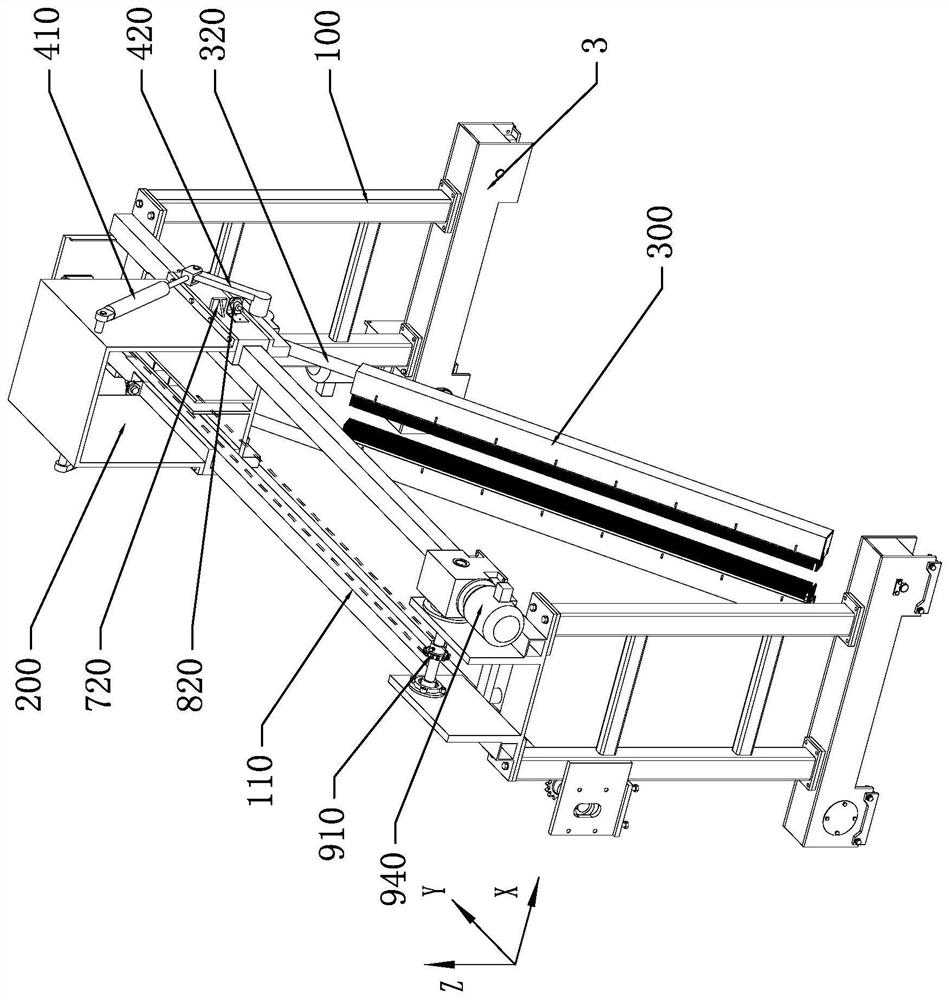

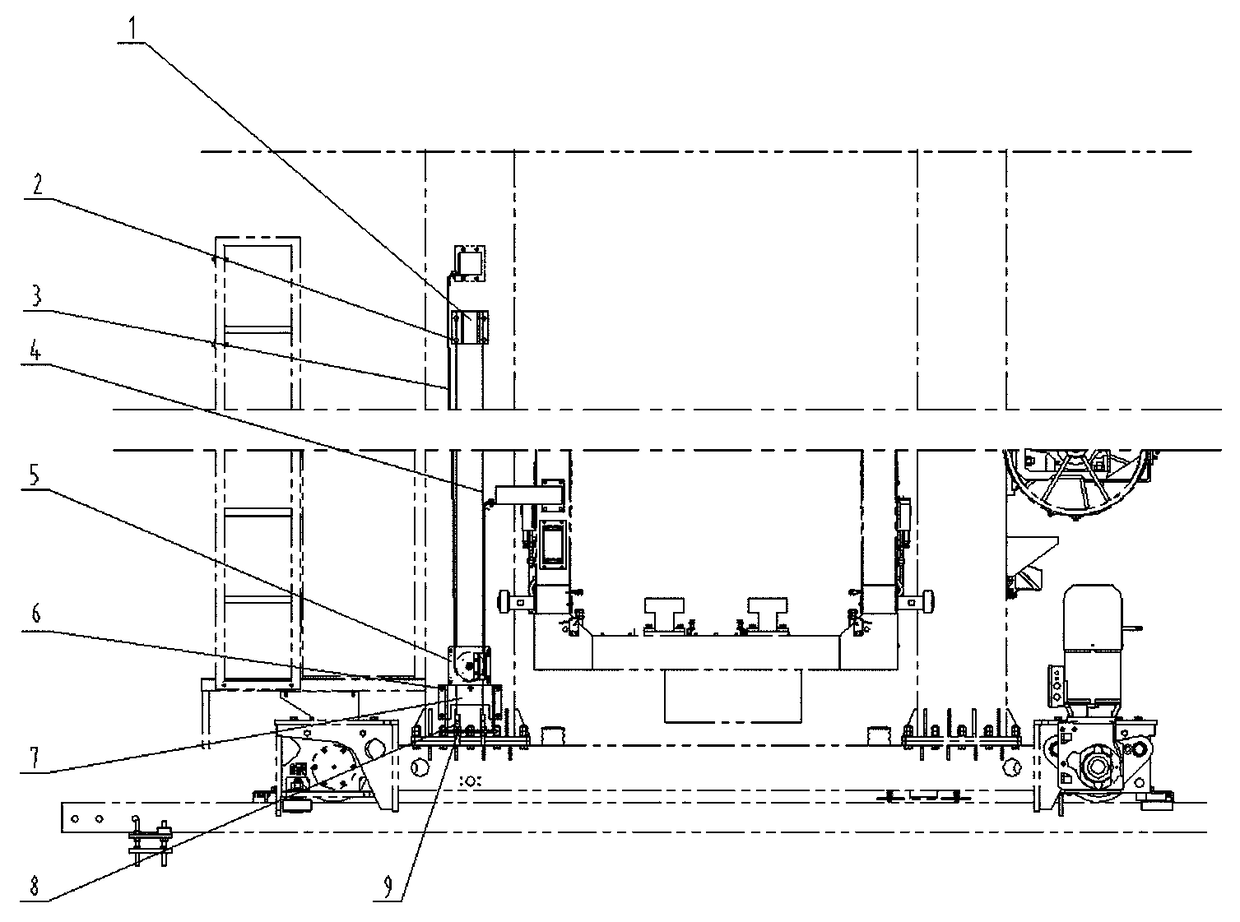

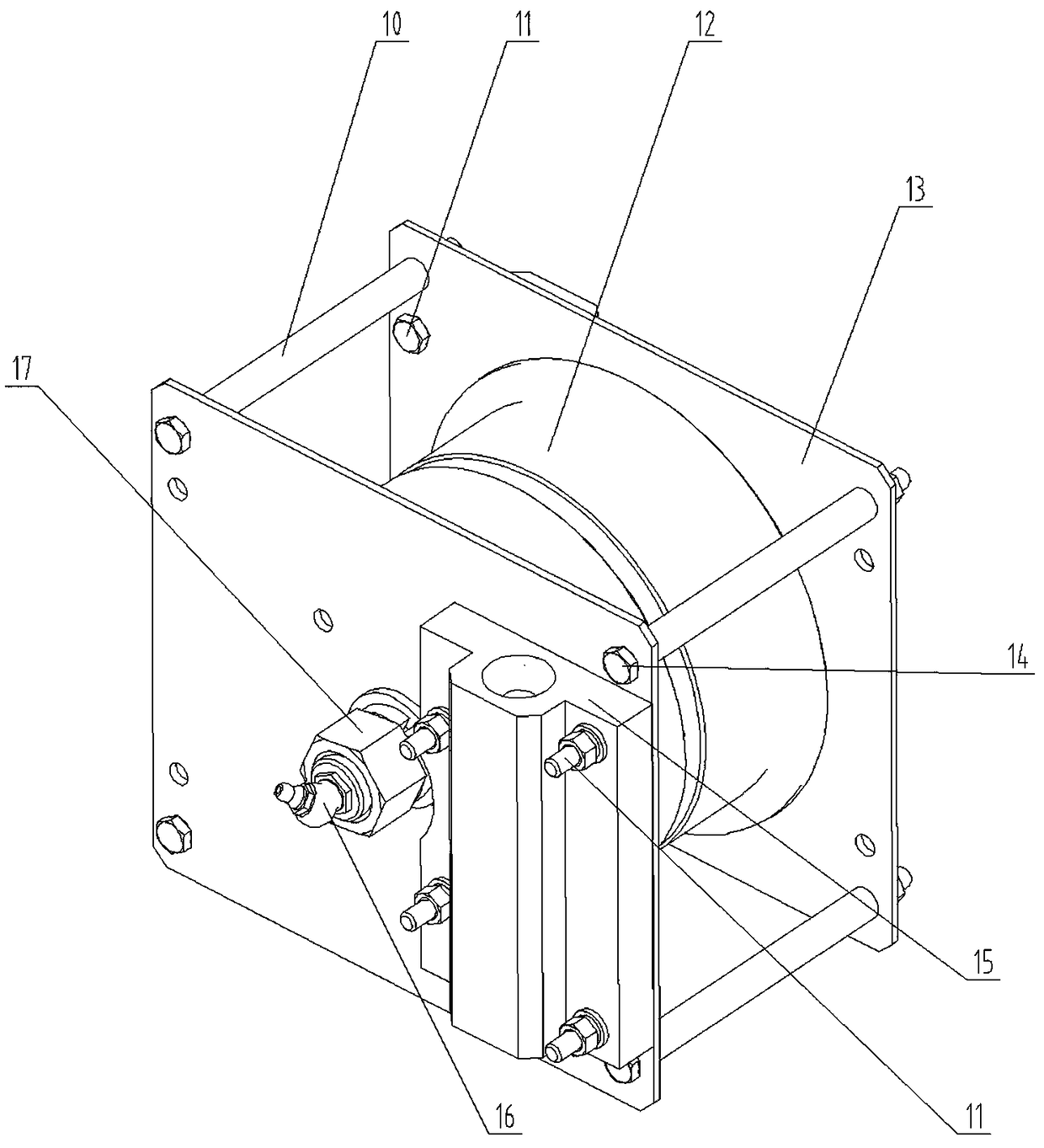

Flat cable lifting device for stacker

InactiveCN109279541AGuaranteed to move normallyWill not interfere with operationLifting devicesEngineeringStacker

The invention relates to a flat cable lifting device for a stacker, and aims to prevent a flat cable from shaking and being worn. The flat cable lifting device for the stacker comprises a lifting wheel assembly, pull rods and supports, wherein the lifting wheel assembly comprises a pulley, pulley installation plates, pulley installation sleeves, a steel wire rope, steel wire rope guide sleeves, apulley shaft and a bearing; the pulley is arranged on the pulley shaft through the bearing; the pulley shaft is inserted between the pulley installation plates; one end of the pulley shaft is fixed through a nut; the pulley installation sleeves are arranged on four corners between the pulley installation plates through bolts; the two steel wire rope guide sleeves are fixed to the front positions and the back positions on the pulley installation plates through bolts; one end of the steel wire rope is fixed onto the pull rod; the other end of the steel wire rope sequentially penetrates through the steel wire rope guide sleeves, the support and the steel wire rope guide sleeves so as to be fixed onto the other pull rod; the two supports are arranged at the positions, close to the lower ends,in the middles of stand columns of the stacker through screws; and the pull rod capable of fixing the steel wire rope is arranged on one support.

Owner:TAIYUAN OTTLE LOGISTICS TECH CO LTD

Diode marking machine

InactiveCN111584406AReduce damage rateAvoid offsetFouling preventionSemiconductor/solid-state device manufacturingEngineeringWorkbench

The invention discloses a diode marking machine which structurally comprises a case, a support, a marking head, a protective cover, a marking base and a workbench. The workbench is connected to the case, the support is installed on the workbench, the support is supported and fixed on the marking head and the protective cover; the bottom of the protective cover is fixed on the marking base; the marking base is mechanically connected with the workbench; the marking base comprises a workpiece feeding channel, a guide mechanism, a clamping pipe, a fixed clamping opening and a supporting rod. A first swing rod, a swing piece and a second swing rod are matched to form a movable rectangular structure, the swing piece is used for limiting the radial area of a workpiece in the horizontal conveyingprocess during workpiece feeding, the situation that deviation is generated due to the influence of the environment wind direction when the workpiece is fed into the fixed clamping opening is avoided,and the damage rate of the workpiece clamped by the fixed clamping opening is reduced.

Owner:李秀碧

clothes dryer

ActiveCN106480684BWill not affect the operationSolve the problem of inconvenient self-cleaning filter deviceTextiles and paperLaundry driersState of artForeign matter

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

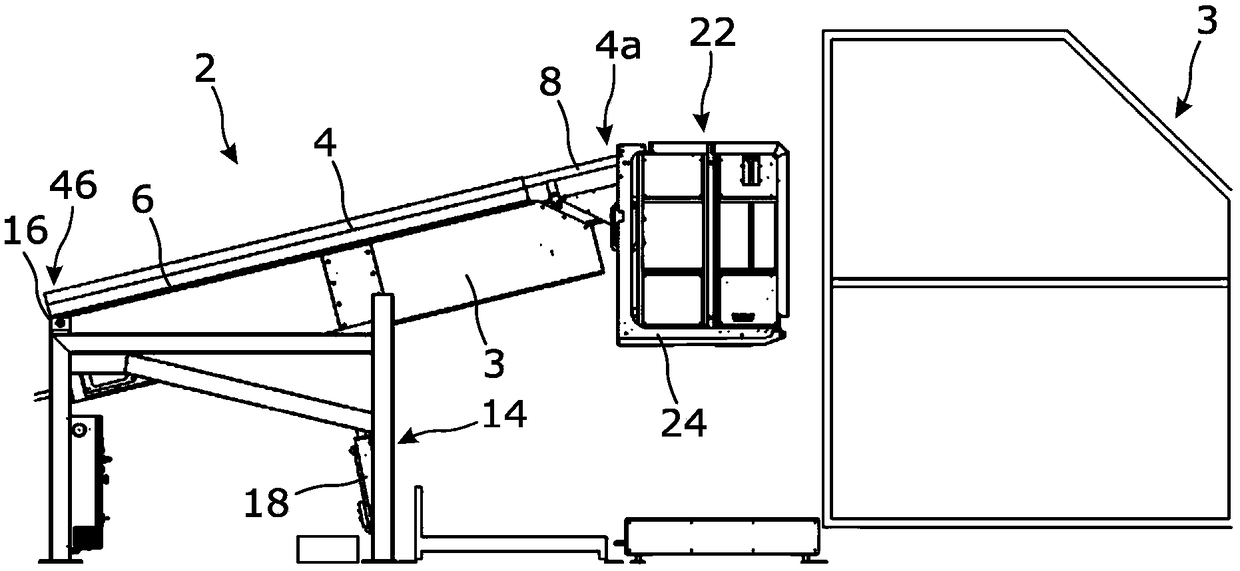

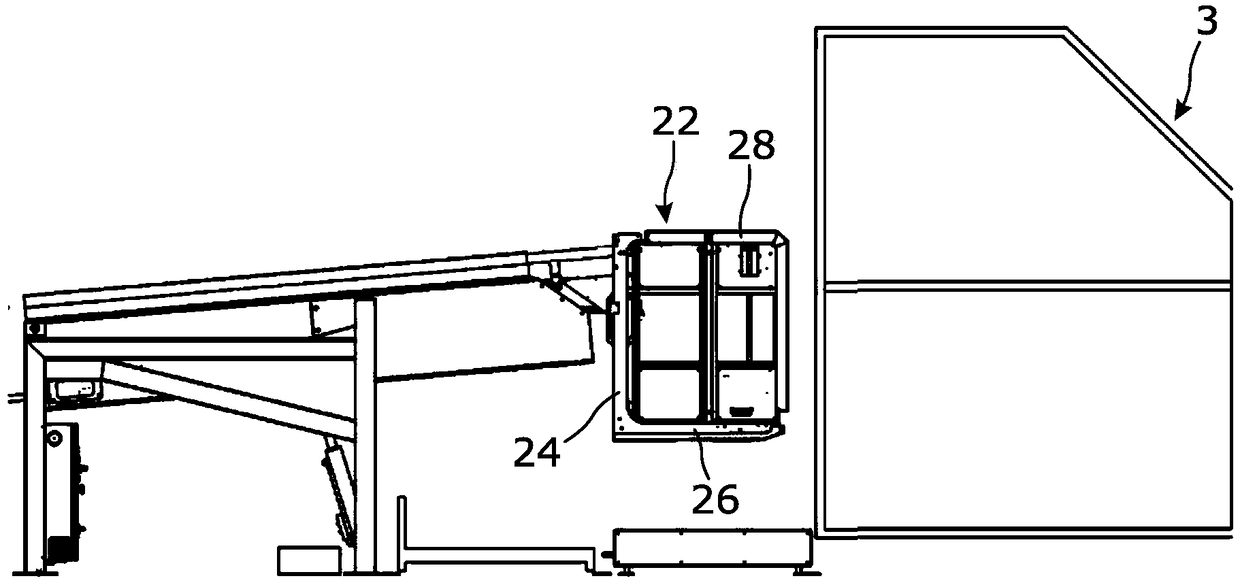

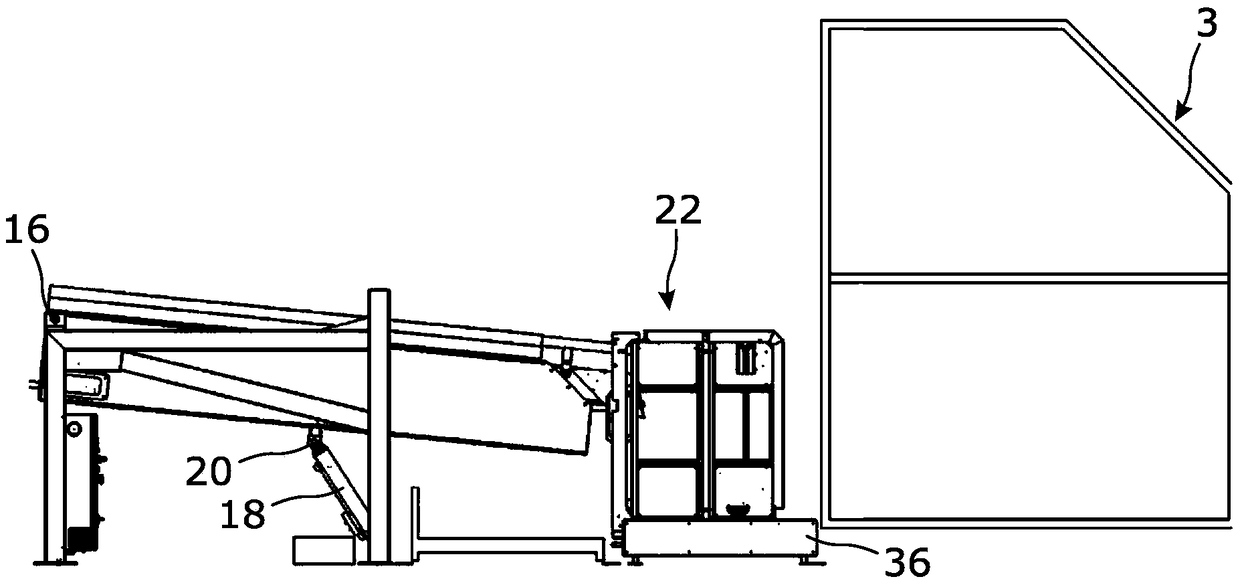

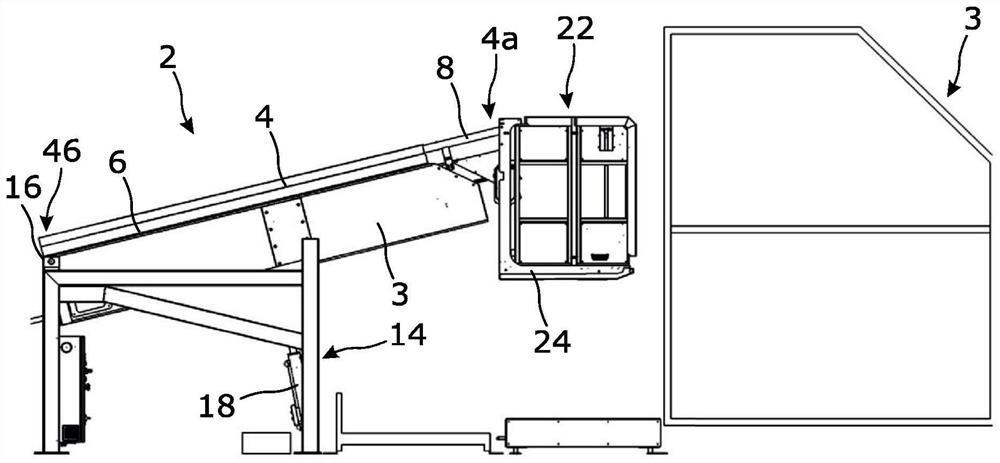

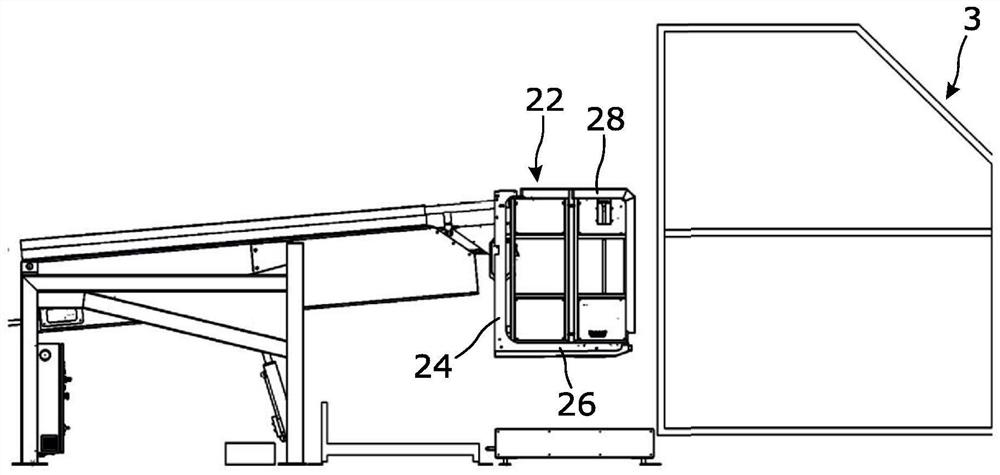

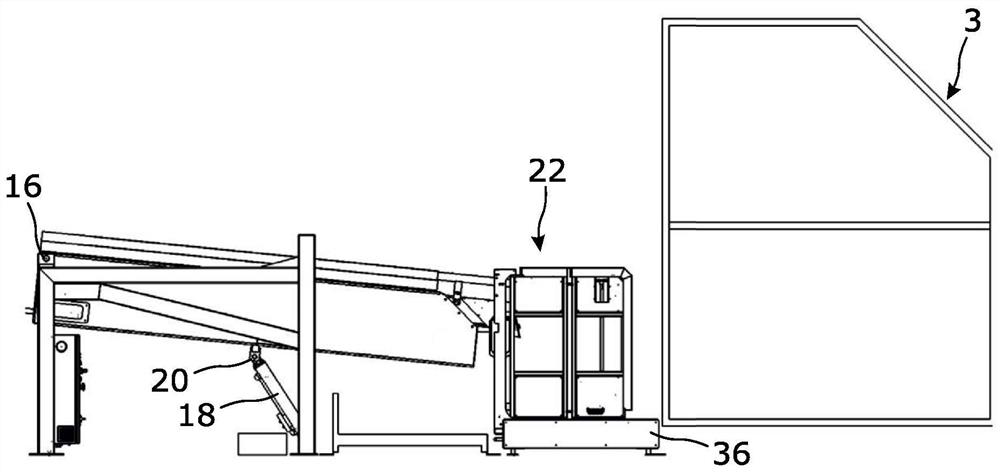

Boom conveyor

ActiveCN109476421ASafe and efficient loading and unloading operationsAvoid riskConveyorsFreight handling installationsCantileverMechanical engineering

A boom conveyor apparatus (3) includes a boom (4) that carries a conveyor (9), a support structure (14) for the boom, a rear pivot joint (16) that connects a rear end of the boom to the support structure, and a pivot drive (18) that controls pivoting movement of the boom about the rear pivot joint. The boom conveyor apparatus (3) includes an operator platform (22) and an attachment mechanism (40)at a front end of the boom (4) whereby the operator platform may be attached to the boom or detached therefrom. The attachment mechanism includes a levelling mechanism (54) that is configured to applya levelling adjustment to the operator platform.

Owner:MARSHALLS CONVEYOR SYST

Cantilever Conveyor

ActiveCN109476421BEnsure safetyWill not interfere with operationConveyorsFreight handling installationsClassical mechanicsCantilever

The cantilever conveyor apparatus (3) comprises: a cantilever (4) carrying the conveyor (9), a support structure (14) for the cantilever, a rear pivot joint (16) connecting the rear end of the cantilever to the support structure, a control Pivot drive (18) for pivotal movement of the boom about the rear pivot joint. The boom conveyor apparatus (3) comprises an operator platform (22) and an attachment mechanism (40) at the front end of the boom (4) enabling the operator platform to be attached to or detached from the boom. The attachment mechanism includes a leveling mechanism (54) configured to apply a leveling adjustment to the operator platform.

Owner:MARSHALLS CONVEYOR SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com