Diode marking machine

A marking machine and diode technology, which is applied in the field of semiconductor processing equipment, can solve the problems of diode pin bending, environmental wind direction rotation, displacement of diode casing, fracture, etc., to reduce the included angle, avoid wear, and reduce damage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

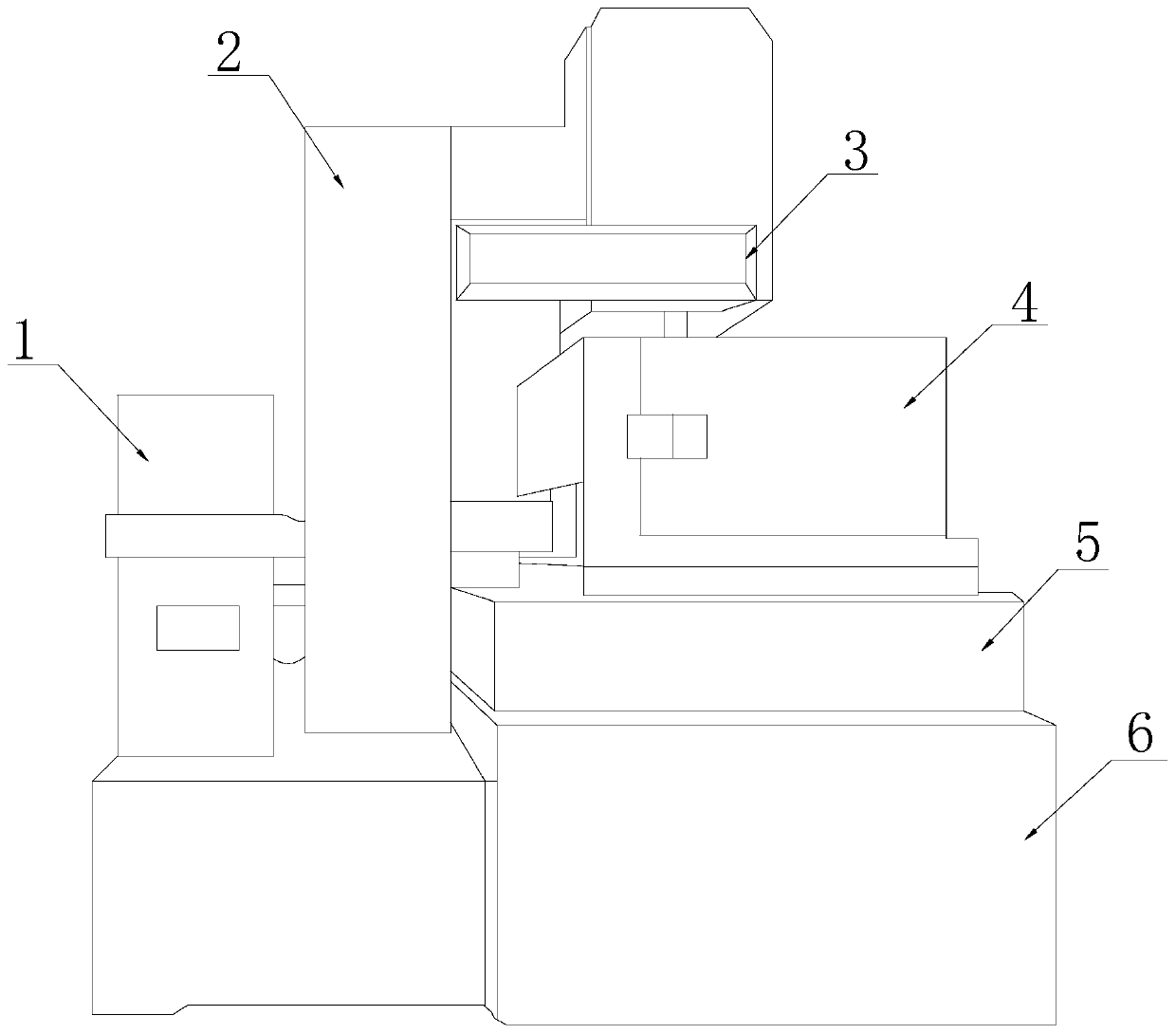

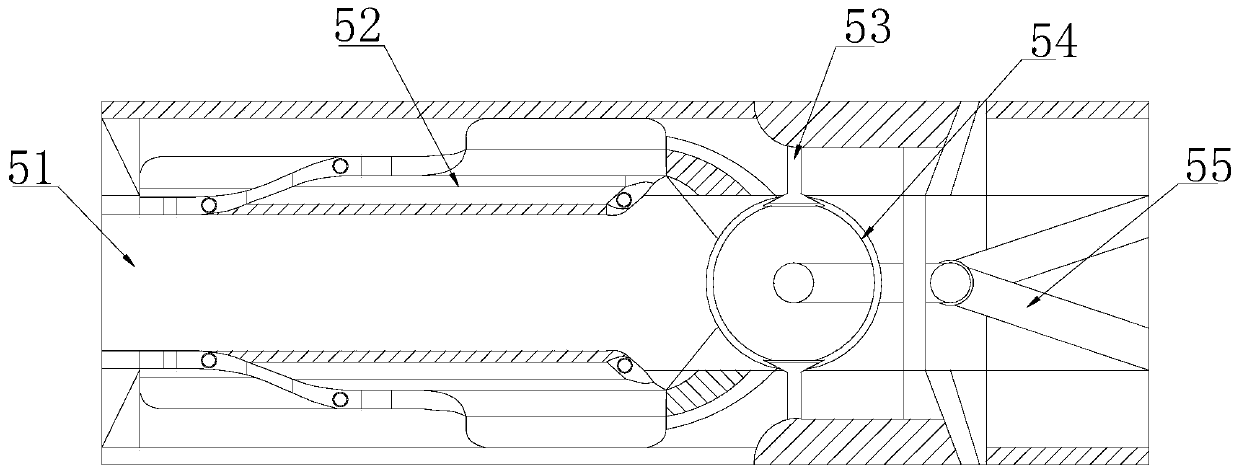

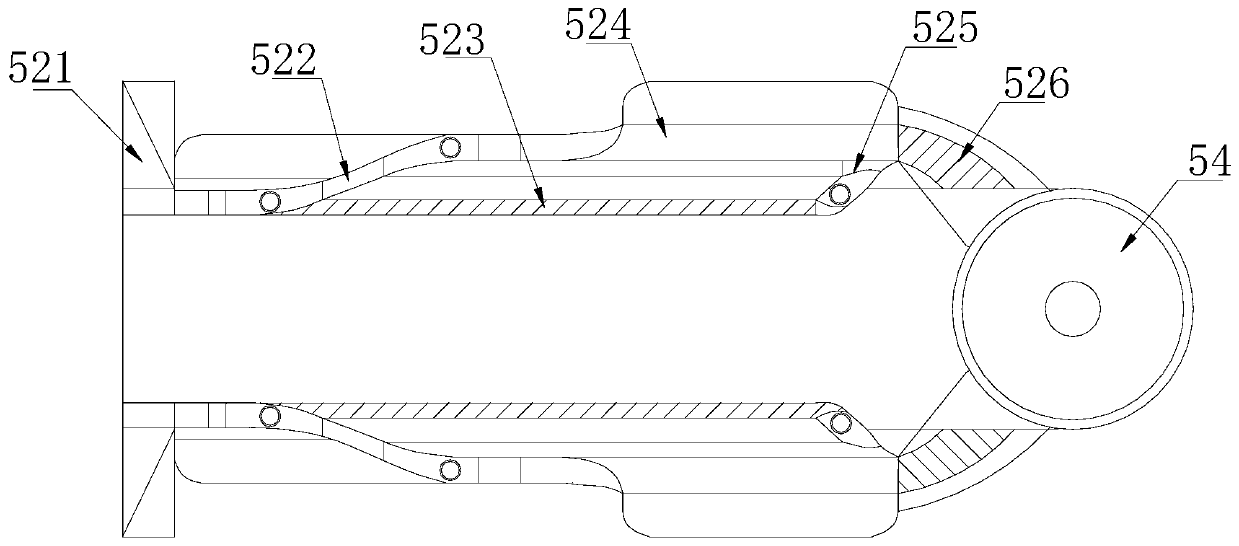

[0033] Such as Figure 1-Figure 6 As shown, the present invention provides a diode marking machine, the structure of which includes a chassis 1, a support 2, a marking head 3, a shield 4, a marking seat 5, and a workbench 6, and the workbench 6 is connected to the chassis 1, Support 2 is installed on the described workbench 6, and this support 2 supports and is fixed on marking head 3 and guard cover 4, and the bottom of described guard cover 4 is fixed on the mark seat 5, and described mark seat 5 and workbench 6. Mechanical connection is adopted. The marking base 5 includes a feeding path 51, a guide mechanism 52, a clamping tube 53, a fixed jaw 54, and a support rod 55. The two sides of the feeding path 51 are respectively provided with a guiding mechanism 52. , the clamping tube 53 fits on the fixed jaw 54 , the fixed jaw 54 is connected and fixed in the feeding channel 51 through the support rod 55 , and the guide mechanism 52 is in clearance fit with the fixed jaw 54 . ...

Embodiment 2

[0040] Such as Figure 7-Figure 8 As shown, on the basis of Embodiment 1, through the mutual cooperation of the following structural components, the buckle 23f includes a ring piece 3f1, a return spring 3f2, a connecting plate 3f3, an inner clip angle 3f4, and a counterweight swivel 3f5. The ring piece 3f1 is arranged inside the connection plate 3f3, the ring piece 3f1 and the return spring 3f2 are semicircular structures, the ring piece 3f1 is in contact with the two ends of the return spring 3f2, and the inner wall of the connection plate 3f3 is equipped with an inner The clamping angle 3f4, the counterweight rotating body 3f5 and the ring piece 3f1 are connected by magnetic adsorption.

[0041] The inner clip angle 3f4 on the right side is in conflict with the ring piece 3f1, the inner clip angle 3f4 on the left side is distributed on both sides of the ring piece 3f1, and does not interfere with each other, and the inner clip angle 3f4 that is in conflict on one side contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com