Flexible packaging substrate and manufacturing method thereof

A flexible packaging and manufacturing method technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems affecting operation, stickiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

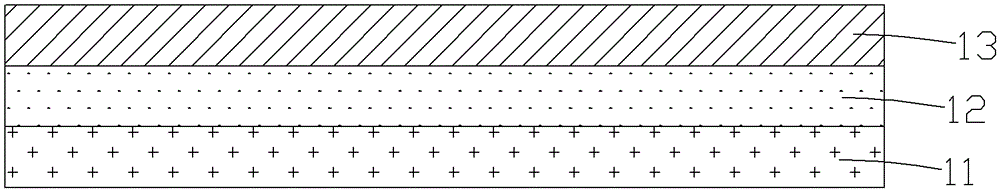

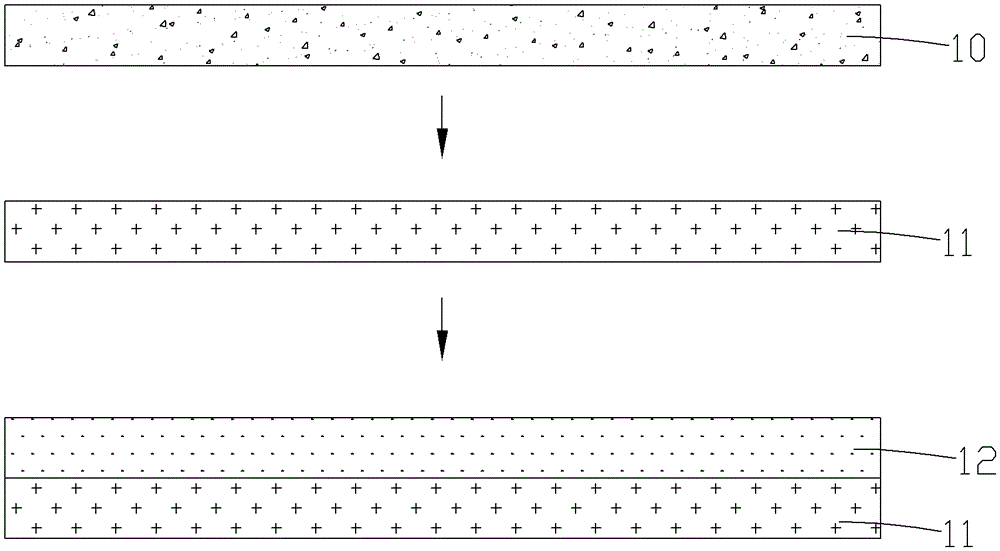

[0052] Production: First use epoxy resin composition, immerse 106 glass fiber cloth on the gluing machine, then pass through the oven of the gluing machine to obtain the semi-cured bonding sheet 10, and then bake the semi-cured bonding sheet 10 at 190℃ for 1.5 A fully cured adhesive sheet (called the cured sheet 11) is obtained in a few hours. One side of the cured sheet 11 and the adhesive film 12 are hot-pressed on the laminating machine, and then punched after hot pressing, and then the release film of the adhesive film 12 Removed and hot-pressed with electrolytic copper foil 13 to obtain figure 1 The flexible packaging substrate of the structure shown.

Embodiment 2

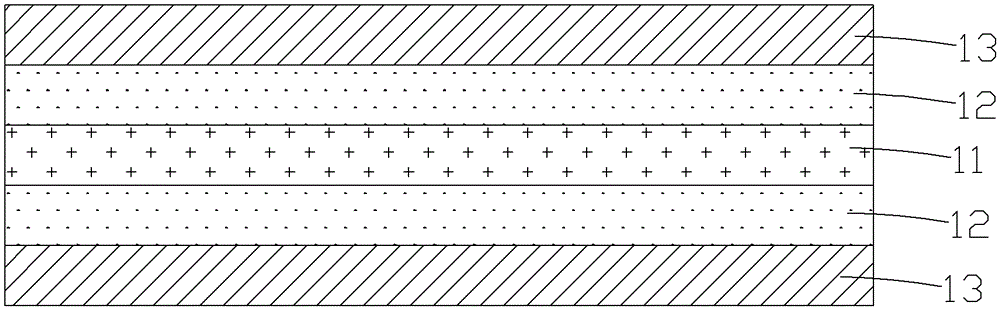

[0054] Production: First use epoxy resin composition to impregnate 1078 glass fiber cloth on the gluing machine, then pass through the oven of the gluing machine to obtain the semi-cured adhesive sheet 10, and then bake the semi-cured adhesive sheet 10 at 190℃ for 1.5 A fully cured adhesive sheet (called cured sheet 11) is obtained in a few hours. The two sides of the cured sheet 11 and the adhesive film 12 are hot-pressed on the laminating machine, and then punched, and then the release film of the adhesive film 12 It is removed and hot-pressed with the electrolytic copper foil 13. Get as figure 2 The structure shown is a flexible packaging substrate.

Embodiment 3

[0056] Production: First use epoxy resin composition, impregnate 1080 glass fiber cloth on the gluing machine, then pass through the oven of the gluing machine to obtain the semi-cured bonding sheet 10, and then bake the semi-cured bonding sheet 10 at 190℃ for 1.5 A fully cured adhesive sheet (called the cured sheet 11) is obtained in a few hours. One side of the cured sheet 11 and the adhesive film 12 are hot-pressed on the laminating machine, and then punched after hot pressing, and then the release film of the adhesive film 12 It is removed and hot-pressed with the rolled copper foil 13. Get as figure 1 The structure shown is a flexible packaging substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com