Glass Products Forming Machine

A technology of glass products and forming machines, applied in glass forming, glass pressing, glass manufacturing equipment, etc., can solve problems such as bottle cracks, expansion and other shape differences, wrinkles, etc., and achieve the effect of preventing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

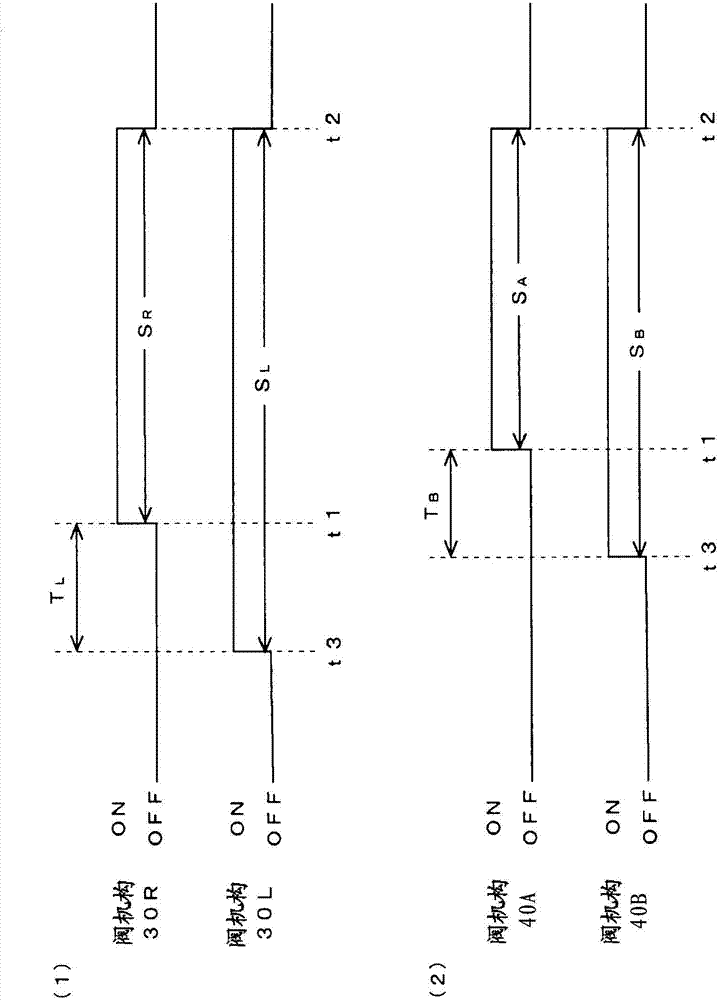

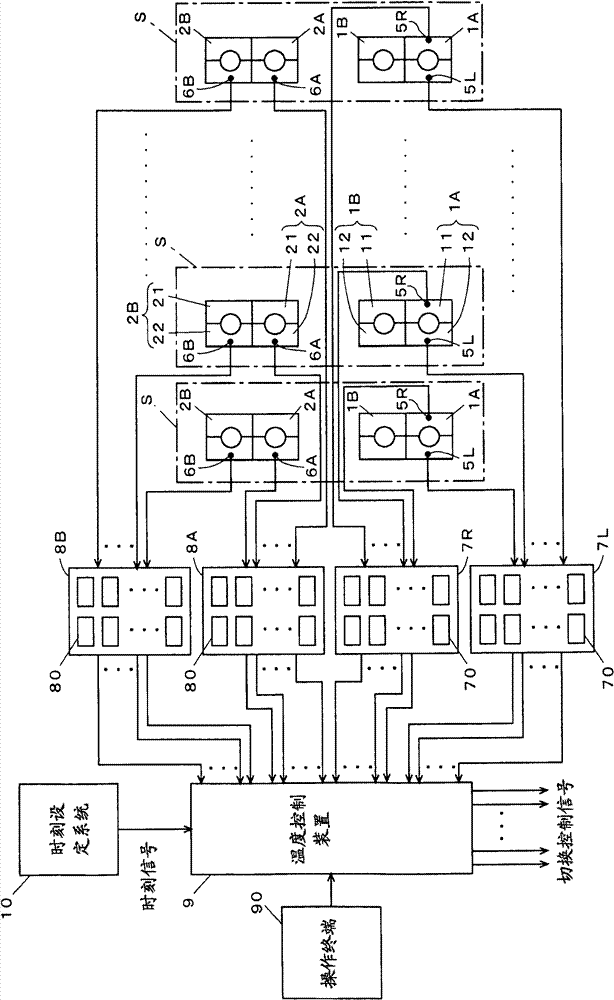

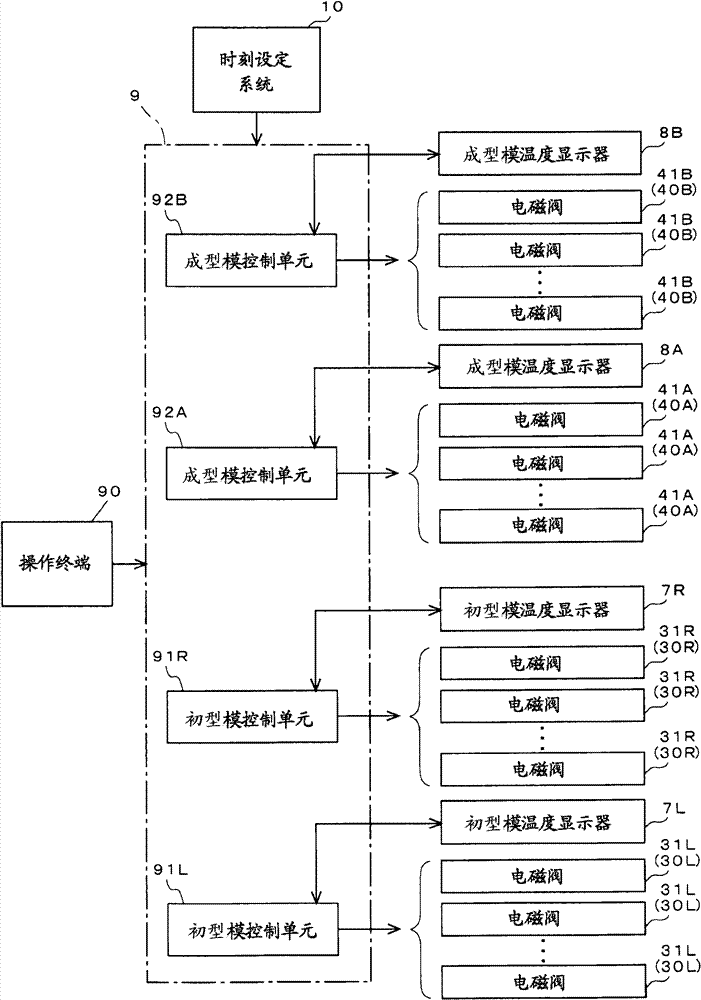

[0057] figure 1 The electric structure of the mold temperature control system of the bottle making machine which is one Example of this invention is shown.

[0058] The bottle making machine of the present embodiment is made up of a plurality of (for example 10) sections S (indicated with dotted line in the figure), in each section, two bottles are manufactured continuously and then conveyed to unillustrated bottles The channel sends out the bottle. In each section S, there are respectively: two initial molds 1A, 1B, which introduce molten glass gobs (gobs) to form parisons; and two forming molds 2A, 2B, which are transported from the respective initial molds 1A, 1B. The preform is finally processed into the final form of the bottle. Each blank mold 1A, 1B has a two-divided structure, and consists of a pair of split molds 11,12. In addition, the molding dies 2A, 2B are also divided into two, and are also composed of a pair of split dies 21, 22.

[0059] In addition, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com