Squeeze riveter with combined jig

A combination fixture and riveting machine technology, applied in the mechanical field, can solve the problems of workpiece damage, difficulty in replacement, and difficult position correction, etc., and achieve the effect of convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

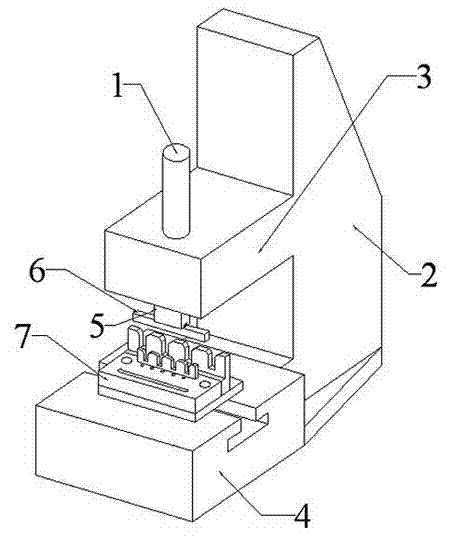

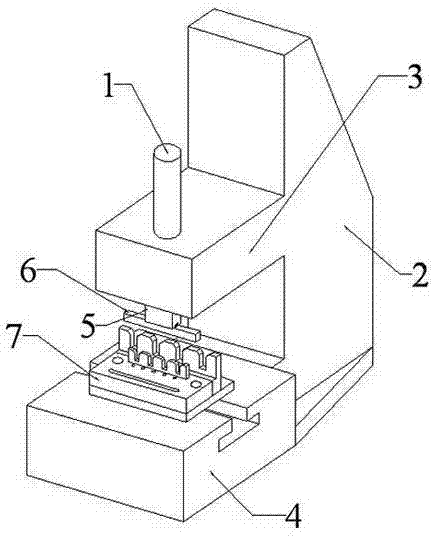

[0014] refer to figure 1 with figure 2 , The riveting machine with combined jig of the present invention includes: air cylinder 1, body 2, pressure head 5, upper die 6 for riveting, lower die assembly 7 for riveting.

[0015] Wherein, the upper half of the body 1 forms a suspension part 2 protruding forward, the lower half of the body 1 forms a fixed seat 3 protruding forward, the cylinder barrel of the cylinder 1 is fixedly connected with the suspension part, and the piston rod of the cylinder 1 The end is fixedly connected with a pressure head 5, the pressure head 5 is fixedly connected with a riveting upper die 6, and the riveting lower die assembly 7 is fixed above the fixing seat 3.

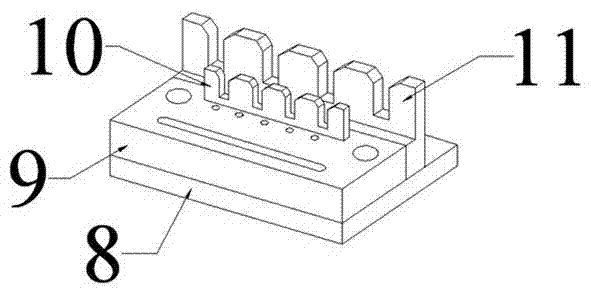

[0016] Such as figure 2 As shown, as a preferred solution, the lower press die assembly 7 includes: a base plate 8, a lower template 9, a first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com