Application of EDTA (ethylene diamine tetraacetic acid) in W-Co composite oxide powder

A composite oxide, tungsten-cobalt technology, applied in the field of metal materials, can solve problems such as unsuitable for hard alloys, achieve high production efficiency, short production cycle, and save production consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

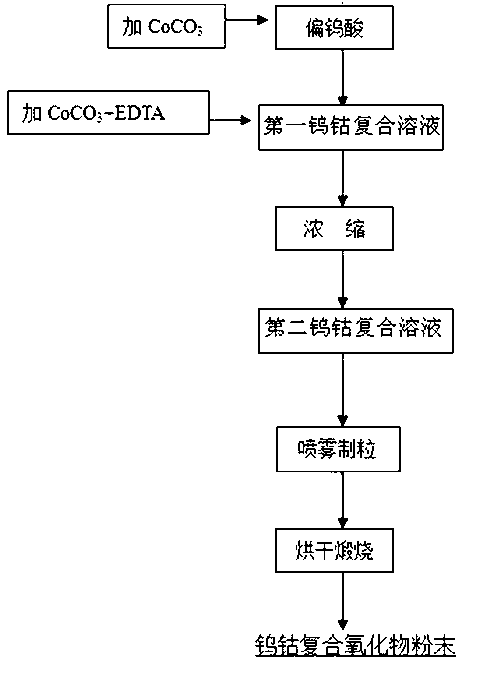

Method used

Image

Examples

Embodiment 1

[0018] (1) Take 750L of metatungstic acid solution, its [H + ]=0.281mol / L, [NH 4 + ]=0mol / L;

[0019] (2) Take by weighing cobalt carbonate powder 15.366kg, EDTA powder 2.409kg for subsequent use;

[0020] (3) Heat the metatungstic acid solution to 80°C, add 13.381kg of cobalt carbonate to make it fully react, and obtain the first tungsten-cobalt composite solution;

[0021] (4) Continue to heat up to 100°C, mix the remaining cobalt carbonate powder and EDTA powder evenly, and then gradually add to the above-mentioned first tungsten-cobalt composite solution to make it react completely to obtain the second tungsten-cobalt composite solution;

[0022] (5) Concentrating the obtained second tungsten-cobalt composite solution, spray drying, drying and calcining to obtain tungsten-cobalt composite oxide powder, the mass percentage of cobalt is 6.72%;

[0023] (6) Carry out reductive carbonization of the above-mentioned tungsten-cobalt composite oxide to obtain tungsten carbide-co...

Embodiment 2

[0025] (1) (obtained by using ammonium metatungstate exchange) take 500L of metatungstate, its [H + ]=0.420mol / L, [NH 4 + ]=0.005mol / L;

[0026] (2) Take by weighing cobalt carbonate powder 19.637kg, EDTA powder 7.592kg for subsequent use;

[0027] (3) Heat the metatungstic acid solution to 70°C, add 13.478kg of cobalt carbonate to make it fully react, and obtain the first tungsten-cobalt composite solution;

[0028] (4) Continue to heat up to 90°C, mix the remaining cobalt carbonate powder and EDTA powder evenly, and then gradually add to the above-mentioned first tungsten-cobalt composite solution to make it react completely to obtain the second tungsten-cobalt composite solution;

[0029] (5) The obtained second tungsten-cobalt composite solution is concentrated, spray-dried, dried and calcined to obtain tungsten-cobalt composite oxide powder, and the mass percentage of cobalt is 8.39%;

[0030] (6) Carry out reductive carbonization of the above-mentioned tungsten-cobal...

Embodiment 3

[0032] (1) (obtained by using ammonium metatungstate exchange) take 750L of metatungstate solution, its [H + ]=0.461mol / L, [NH 4 + ]=0.01mol / L;

[0033] (2) Take by weighing cobalt carbonate powder 48.206kg, EDTA powder 26.024kg for subsequent use;

[0034] (3) Heat the metatungstic acid solution to 60°C, add 26.892kg of cobalt carbonate to make it fully react, and obtain the first tungsten-cobalt composite solution;

[0035] (4) Continue to heat up to 80°C, mix the remaining cobalt carbonate powder and EDTA powder evenly, and then gradually add to the above-mentioned first tungsten-cobalt composite solution to make it react completely to obtain the first tungsten-cobalt composite solution;

[0036] (5) Concentrating the obtained second tungsten-cobalt composite solution, spray drying, drying and calcining to obtain tungsten-cobalt composite oxide powder, the mass percentage of cobalt is 10.05%;

[0037] (6) Carry out reductive carbonization of the above-mentioned tungsten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com