Mold for conveniently de-molding injection molded products

A technology for injection molding products and molds, which is applied in the field of molds that facilitate the demolding of injection molding products, can solve problems such as increasing production costs, and the products cannot be produced smoothly, and achieves the effect of a simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

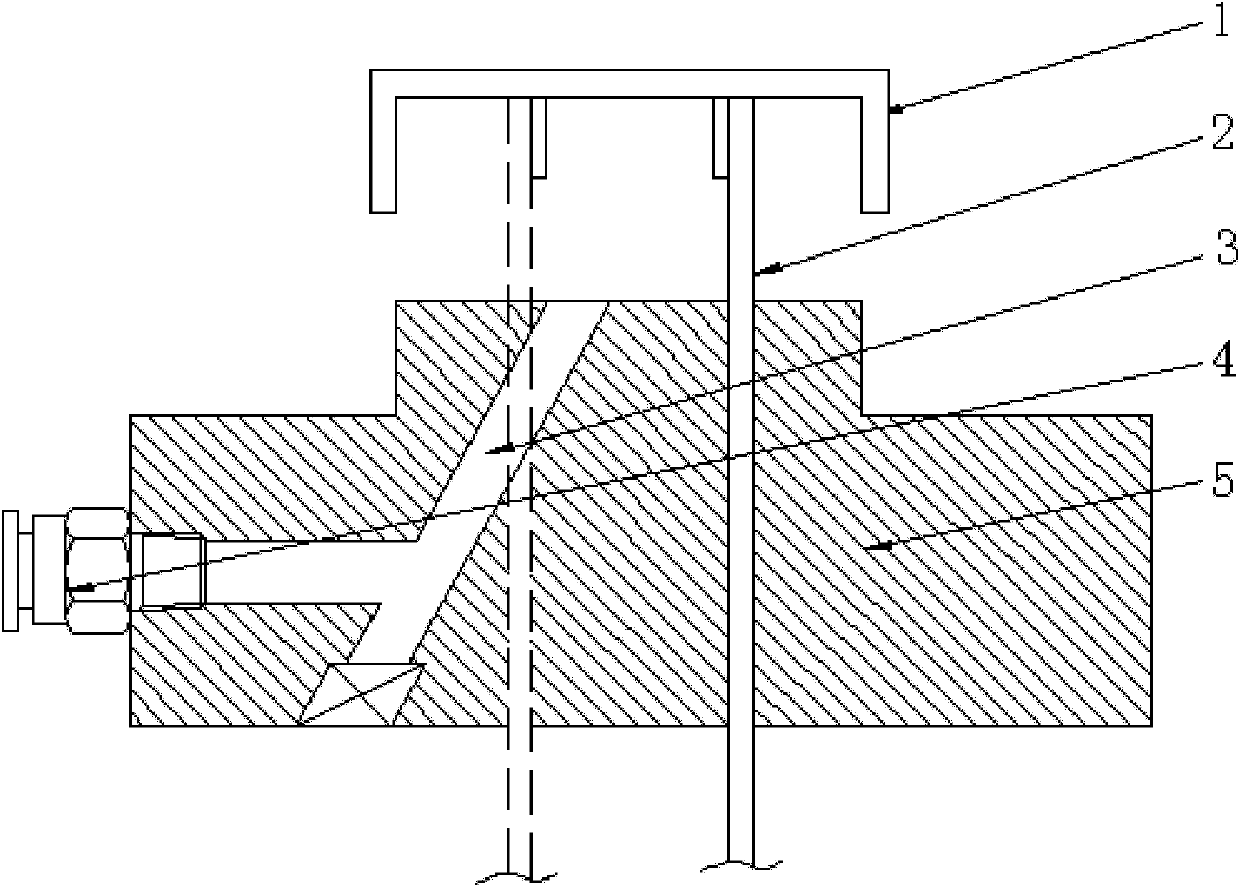

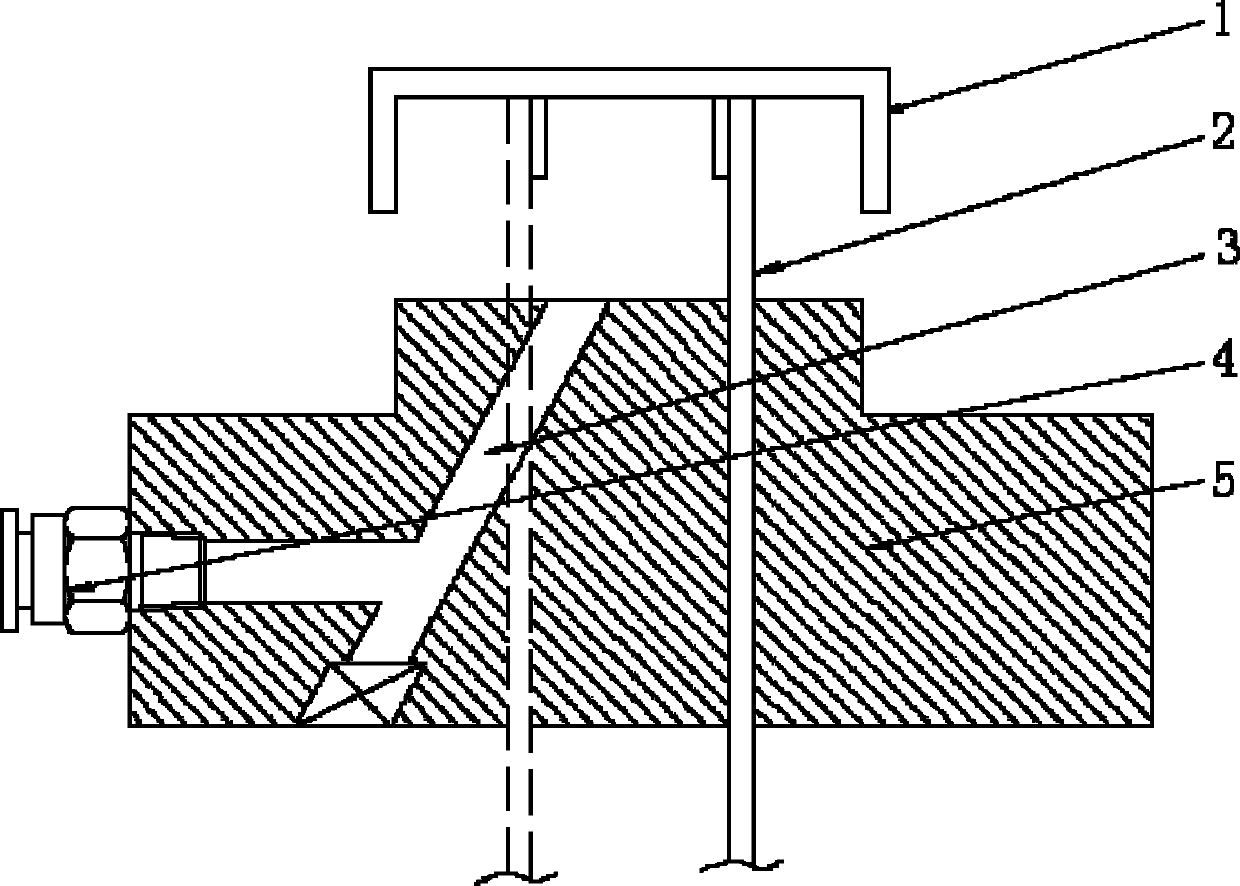

[0015] Such as figure 1 Shown, a kind of mold that is convenient for demoulding of injection molded product, this mold comprises mold body 5, blowing device. Two air hole passages 3 are arranged on the mold body 5, and one end of the air hole passage 3 is an air blowing outlet, and the air blowing outlet is arranged on the mold facing the demoulding direction of the product 1. The other ends of the pore passages 3 converge to form an air inlet, which is threadedly connected with the trachea joint 4 . The cross section of the air hole channel 3 is circular. After the product 1 is ejected from the mold for a certain distance, the blowing device sends air from the air pipe joint 4, the gas flows in along the air hole channel, and finally blows to the product 1 from the blowing outlet, so that the product 1 falls from the mold 5.

Embodiment 2

[0017] refer to figure 1 , a mold for easy demolding of injection molded products, the mold includes a mold body and an air blowing device. The mold body is provided with 30 air hole channels, and one end of the air hole channel is a blowing outlet, and the blowing outlet is arranged on the mold facing the demoulding direction of the product. The other ends of the pore channels are collected to form an air inlet, which is threadedly connected with the trachea joint. The cross-section of the stomatal channel is circular. When the product is ejected from the mold for a certain distance, the blowing device sends air from the air pipe joint, the gas flows in along the air hole channel, and finally blows to the product from the blowing outlet, so that the product falls from the mold.

Embodiment 3

[0019] refer to figure 1 , a mold for easy demolding of injection molded products, the mold includes a mold body and an air blowing device. The mold body is provided with 10 air hole channels, and one end of the air hole channel is a blowing outlet, and the blowing outlet is arranged on the mold facing the demoulding direction of the product. The other ends of the pore channels are collected to form an air inlet, which is threadedly connected with the trachea joint. The cross-section of the stomatal channel is circular. When the product is ejected from the mold for a certain distance, the blowing device sends air from the air pipe joint, the gas flows in along the air hole channel, and finally blows to the product from the blowing outlet, so that the product falls from the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com