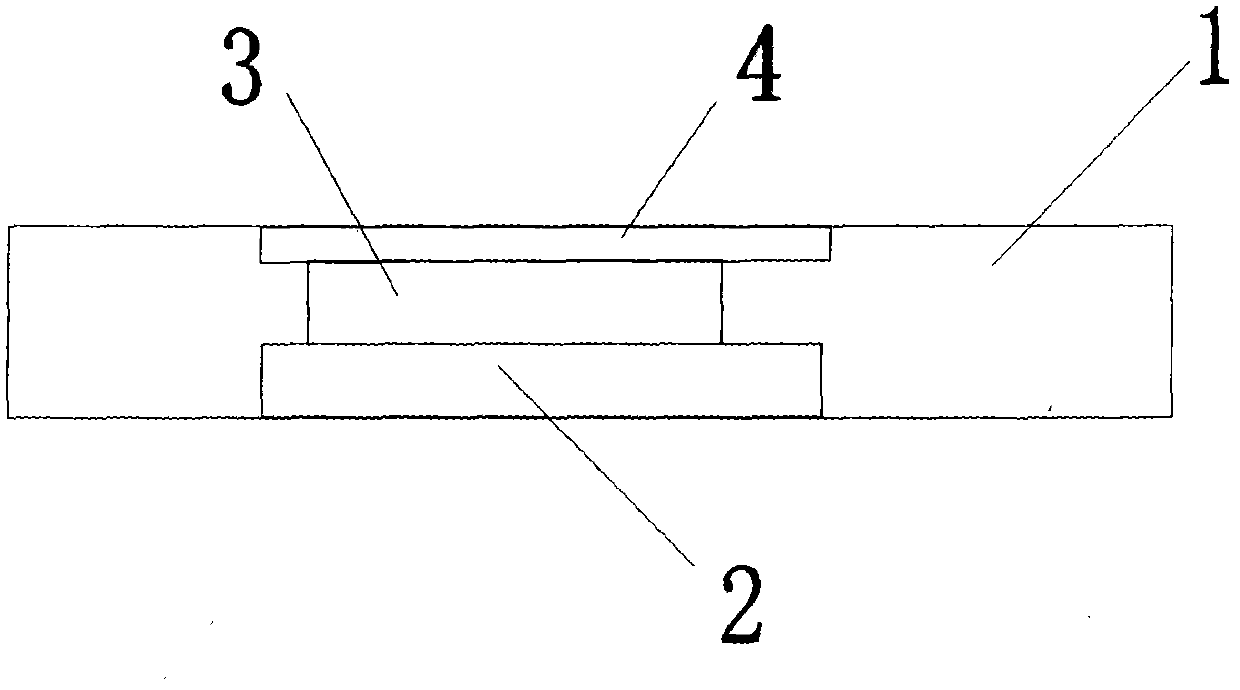

Printing stock with local 3D (Three-Dimensional) stereoscopic effect and printing method thereof

A technology of three-dimensional effect and substrate, applied in printed matter and its production, substrate with local 3D three-dimensional effect and its printing field, can solve the problems of high price, high printing difficulty, waste of raw materials, etc. Beautiful, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

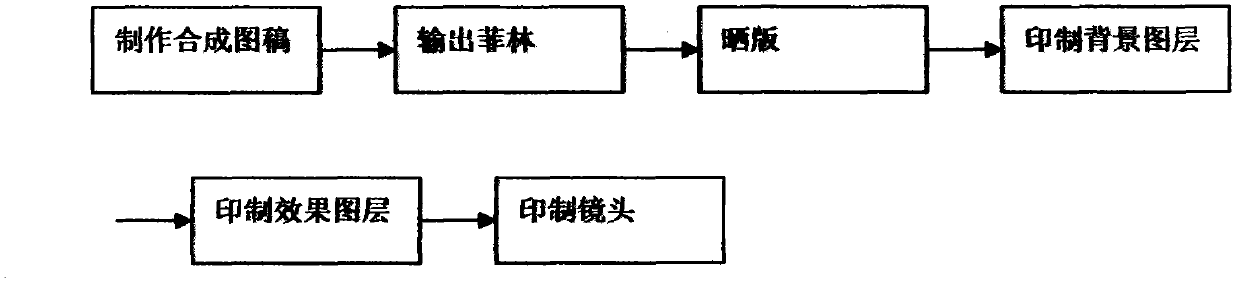

[0060] Such as figure 2 As shown, the method for printing a substrate with a partial 3D stereoscopic effect comprises the following steps:

[0061] Step 1. According to the needs, select the key patterns that need to be highlighted, and use computer software to design and produce local 3D stereoscopic effects by professional designers. The specific steps include the following:

[0062] 1. Select and outline the key patterns that need to be highlighted;

[0063] 2. Choose to make a background layer;

[0064] 3. Fill the background layer around the effect layer;

[0065] 4. Select the shape of the production lens;

[0066] 5. Fill the lens at the place corresponding to the background layer;

[0067] 6. Synthesize with the original artwork.

[0068] The second step is to output the finished composite artwork to the film with a high-resolution film output machine, which specifically includes the following steps:

[0069] 1. Use four-color plus white-backed film to print the e...

Embodiment 2

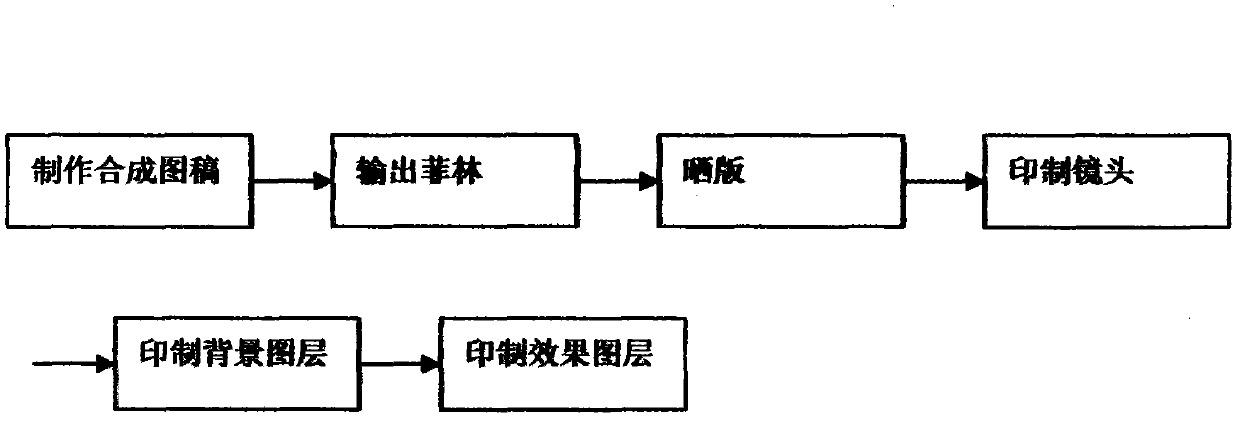

[0082] Such as image 3 As shown, the method for printing a substrate with a partial 3D stereoscopic effect comprises the following steps:

[0083] Step 1. According to the needs, select the key patterns that need to be highlighted, and use computer software to design and manufacture the local 3D stereo effect by professional designers. The specific steps include the following:

[0084] 1. Select and outline the key patterns that need to be highlighted;

[0085] 2. Choose to make a background layer;

[0086] 3. Fill the background layer around the effect layer;

[0087] 4. Select the shape of the production lens;

[0088] 5. Fill the lens at the place corresponding to the background layer;

[0089] 6. Synthesize with the original artwork.

[0090] The second step is to output the finished composite artwork to the film with a high-resolution film output machine, which specifically includes the following steps:

[0091] 1. Use four-color plus white-backed film to print the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com