Pneumatic tire carcass with non-continuous ply in the bead areas

A technology for pneumatic tires and plies, which is applied to the reinforcement layers, tire parts, tire edges and other directions of pneumatic tires, can solve problems such as low performance and excessive use of tire reinforcements, reduce tire weight and cost, and prevent excessive work. , to eliminate the overlapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

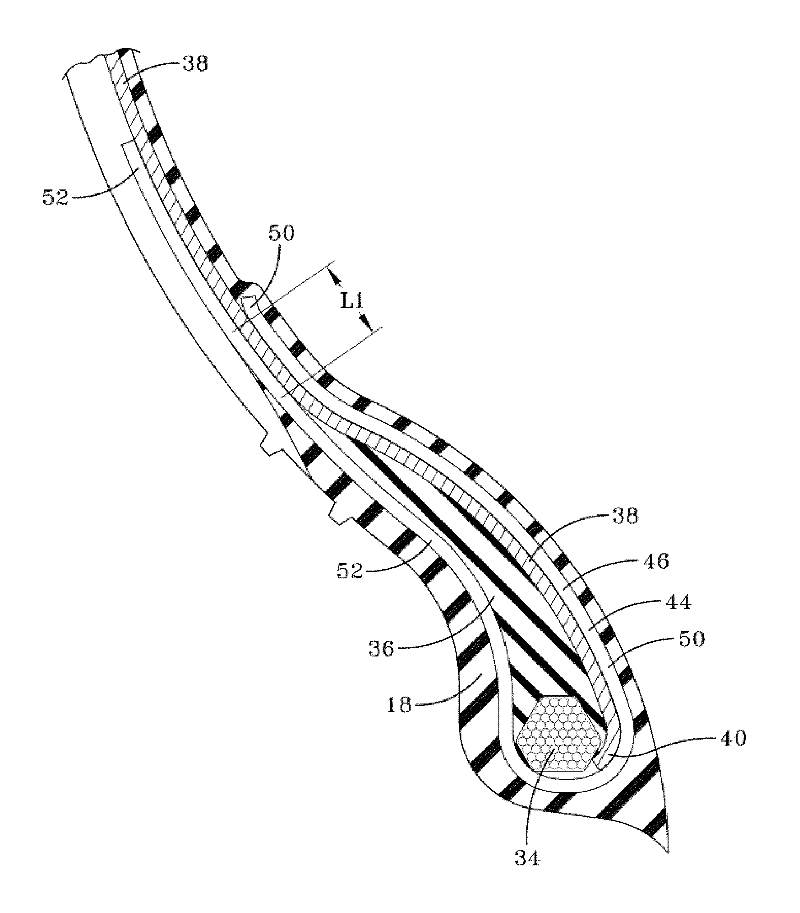

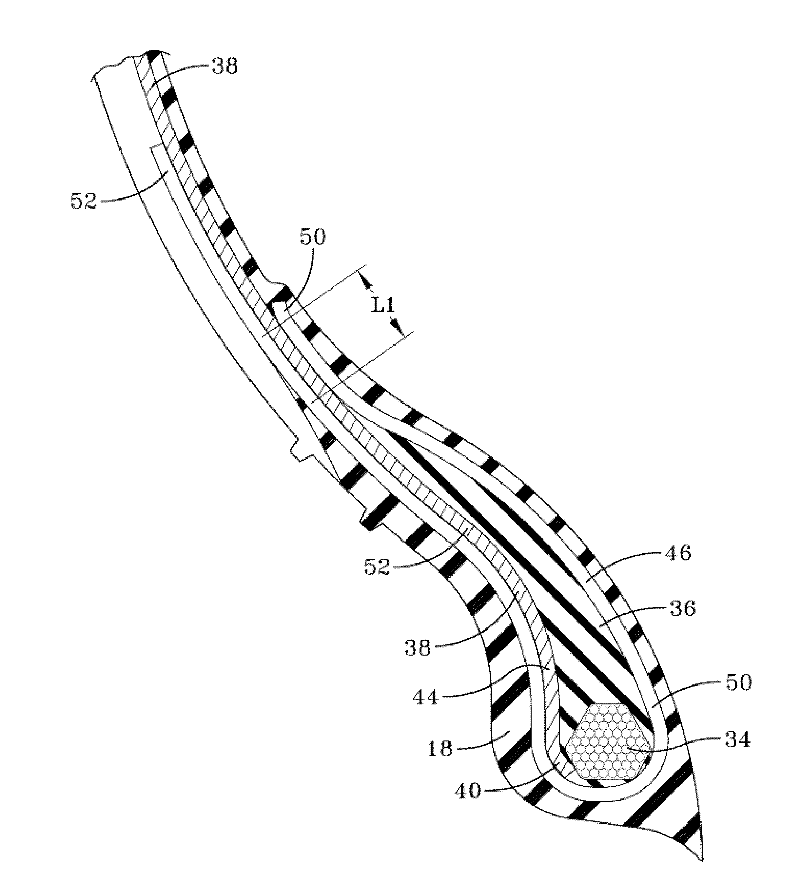

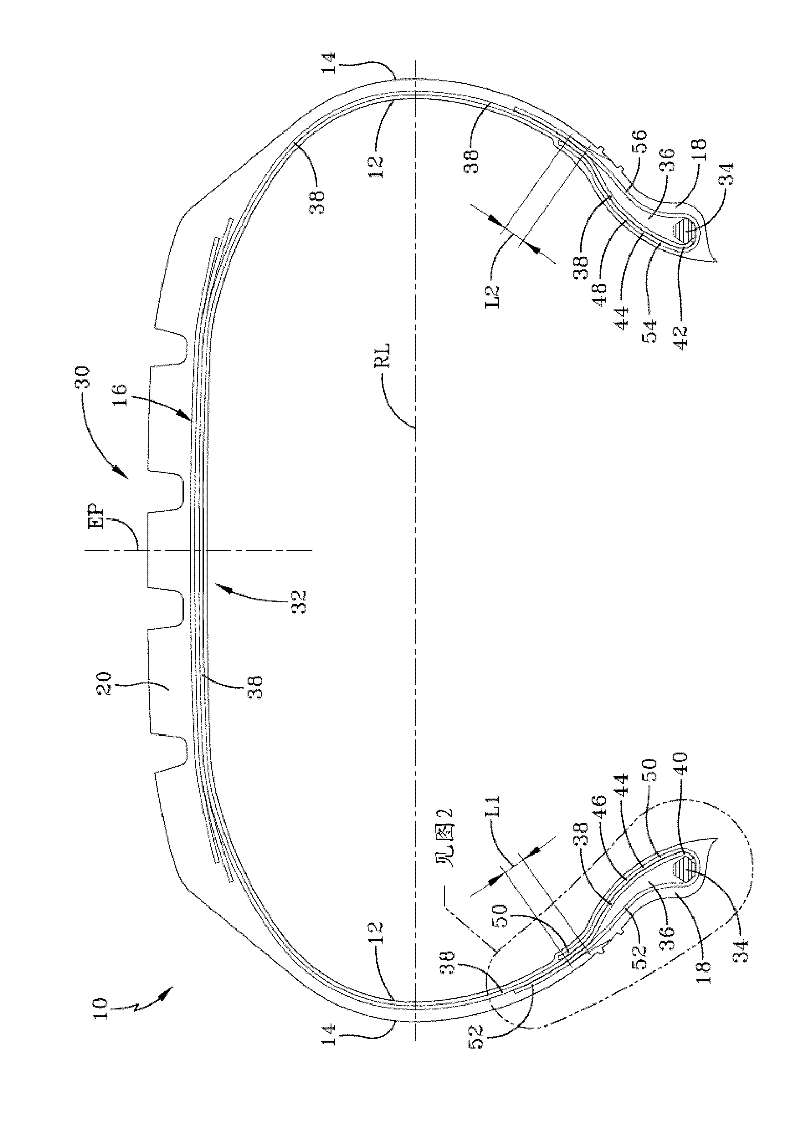

[0035] Referring now to the drawings, wherein the drawings are only for illustration of illustrated embodiments of the invention and are not intended to limit the invention, wherein like reference numerals should be understood to refer to like parts, figure 1 A pneumatic tire 10 having a carcass 30 according to one embodiment of the present invention is shown. The non-carcass portions of tire 10 may be of any conventional design and may include innerliner 12 on the inner surface of carcass 30 and sidewall rubber portions 14 , 14 on the sides of the outer surface of carcass 30 . The chafers 18 , 18 may be located below the sidewall rubber 14 on the underside of the outer surface of the carcass 30 . The belt assembly 16 may be located on a crown portion 32 of the outer surface of the carcass 30, and the tread 20 may be located on the belt assembly 16. As these components are quite familiar to those skilled in the art, further details are not provided herein. The pneumatic tire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com