Spiral-flow type built-in cylindrical blast cap

A swirling and cylindrical technology, applied in the field of fluidized bed, can solve the problems of easy fluidization "dead zone" at the bottom of the bed, mutual erosion and wear of wind caps, poor fluidization uniformity, etc., to improve fluidization quality , prolong service life, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

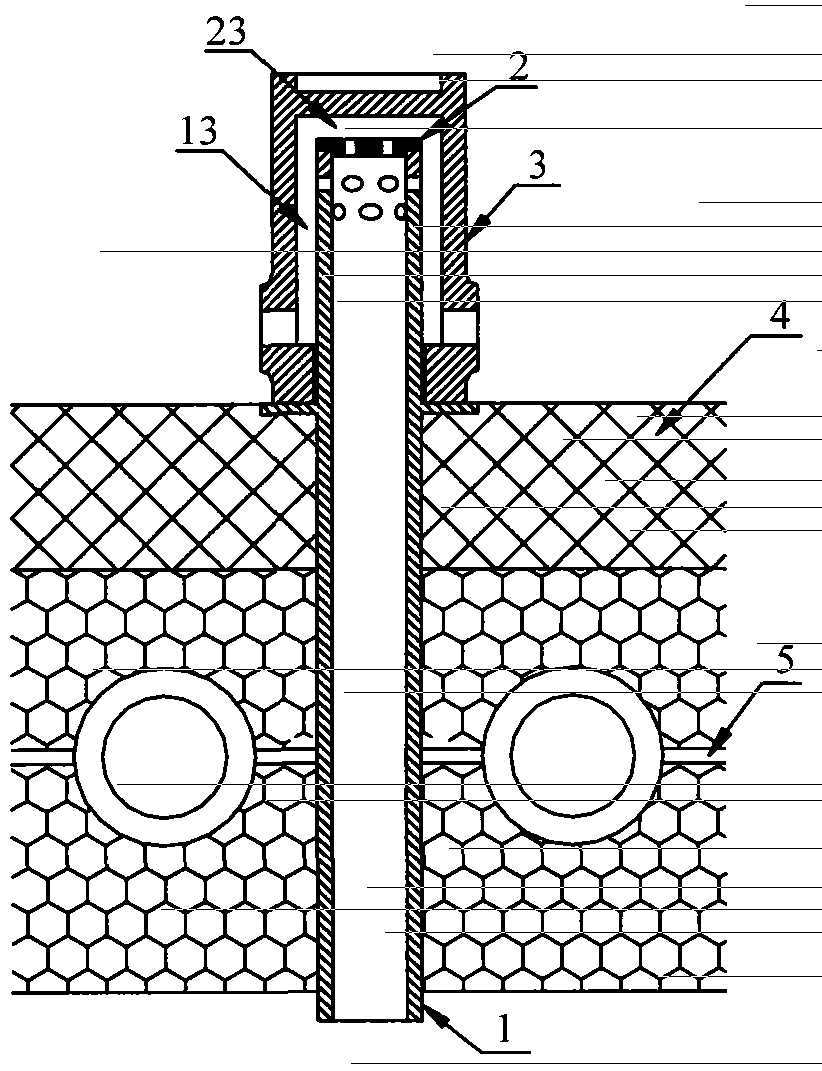

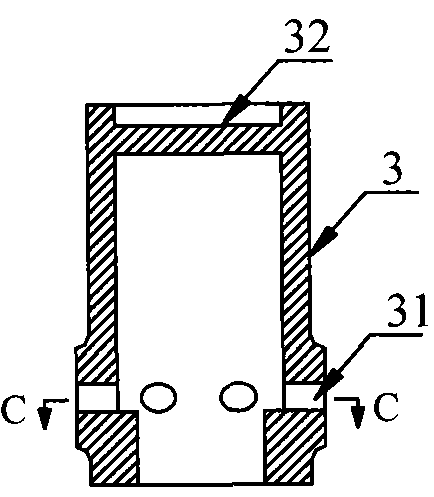

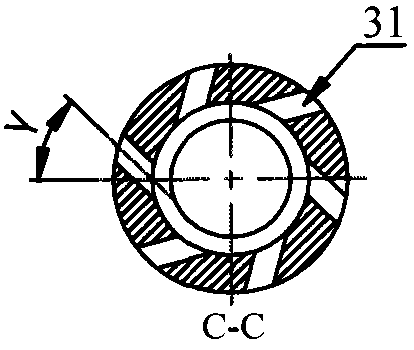

[0063] refer to figure 1 , 2 , 3, 4, 5, 6, 7 and 8, the present invention provides a swirl inlaid cylindrical air cap, which is composed of an inlaid pipe 1, a throttle block 2 and an outer sleeve 3. The inlaid pipe 1 is a straight pipe section with two open ends. The upper side wall of the inlaid pipe 1 is arranged with two layers of through holes 11 and 12 horizontally from the inside to the outside. The through holes 11 and 12 are counterclockwise along the inner wall of the inlaid pipe. The horizontal deflection angle α is 45°; the lower end of the outer casing 3 is open and the upper end is closed, and the side wall of the lower section of the outer casing 3 is provided with a through hole 31 horizontally arranged from the inside to the outside, and the through hole 31 along the inner wall of the outer casing clockwise horizontal deflection angle γ is: 45°, the outer casing 3 is coaxially buckled outside the inner tube 1, the inner diameter of the lower section of the ou...

Embodiment 2

[0066] refer to Figure 9 , 10 , 11 , 12 , 13 , 14 and 15 , the present invention provides a swirl-type embedded cylindrical hood, which is composed of an embedded tube 1 , a blind plate 2 ′ and an outer sleeve 3 . The inlaid pipe 1 is a straight pipe section with two open ends. The upper end side wall of the inlaid pipe 1 is arranged with two layers of through holes 11 and 12 horizontally from the inside to the outside. The through holes 11 and 12 are clockwise along the inner wall of the inlaid pipe. The horizontal deflection angle α is 30°; the lower end of the outer casing 3 is open, and the upper end is closed, and the side wall of the lower section of the outer casing 3 is provided with a through hole 31 horizontally arranged from the inside to the outside, and the through hole 31 along the inner wall of the outer casing. The horizontal deflection angle γ in the counterclockwise direction is 30°, the outer casing 3 is coaxially buckled outside the inner tube 1, the inne...

Embodiment 3

[0068] refer to Figure 16 , 17 , 18, 19, 20 and 21, the present invention provides a swirl in-line cylindrical hood, which consists of an in-line tube 1 and an outer sleeve 3 . The inlaid pipe 1 is a straight pipe section with two open ends. The upper end side wall of the inlaid pipe 1 is inclined downward from the inside to the outside to arrange the second-layer through holes 11 and 12, and the downward inclination angle δ is 15°. The through holes 11 and the through holes 12. The horizontal deflection angle α along the inner wall of the inner tube is 60° in the counterclockwise direction; the lower end of the outer tube 3 is open, and the upper end is closed, and the side wall of the lower section of the outer tube 3 is provided with through holes 31 horizontally arranged from the inside to the outside, and the through holes 31 are arranged along the inner surface of the outer tube. The horizontal deflection angle α of the wall in the clockwise direction is 60°, the outer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap