Method for testing deflection/longitudinal displacement change of bridge based on four-quadrant position detector

A four-quadrant detector and bridge deflection technology, used in instruments, measuring devices, optical devices, etc., can solve the problems of low measurement accuracy and can not meet the requirements of bridge deflection measurement, so as to ensure accuracy and make up for the reduction of measurement accuracy. , good detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

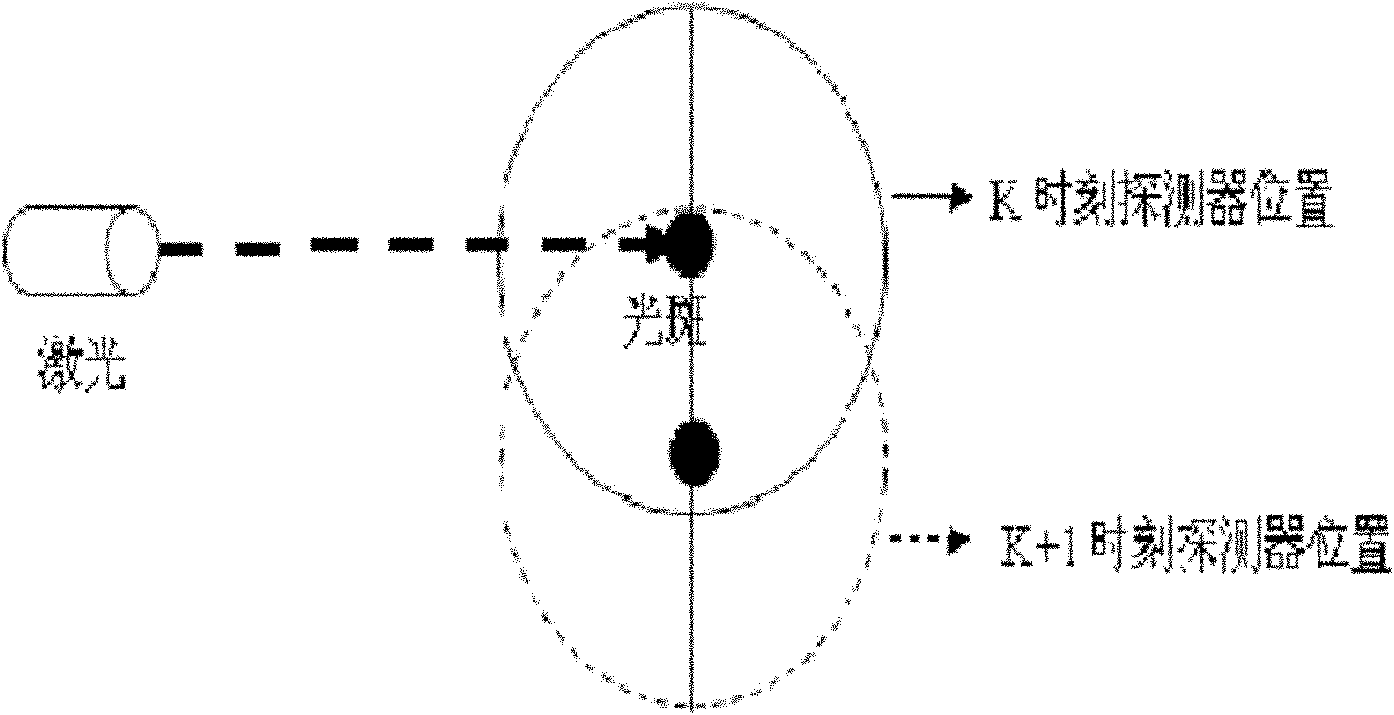

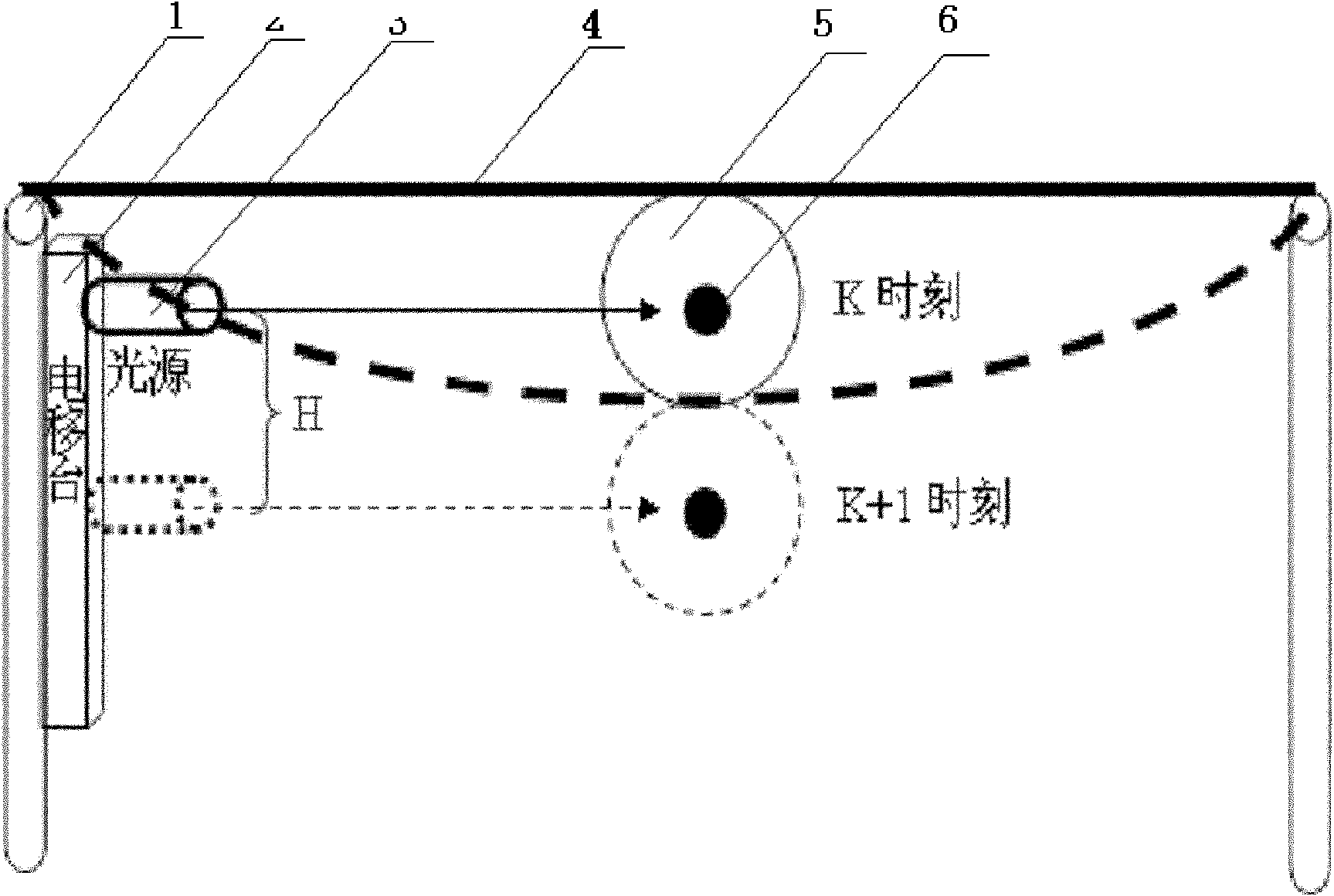

[0040] like figure 2 shown. The span aperture of the bridge 4 is within 300m, the four-quadrant detector 5 is fixed in the middle of the bridge 4, and the laser light source 3 is installed on the pier 1 through the electric shift table 2 to measure the deflection value. Ensure that the light spot 6 of the laser hits the photosensitive surface of the four-quadrant detector 5 vertically. At time K (before the deflection of the bridge changes), spot 6 hits the center of the four-quadrant detector 5, and at time K+1 (after the deflection of the bridge changes), spot 6 cannot hit due to the large deflection change of bridge 4 On the photosensitive surface of the four-quadrant detector 5, at this moment, the position of the light source 3 is adjusted by controlling the electric shift stage 2, so that the light spot 6 hits the center of the photosensitive surface of the four-quadrant detector 5 again. The distance H moved by the electric moving stage 2 is obtained by measurement. ...

Embodiment 2

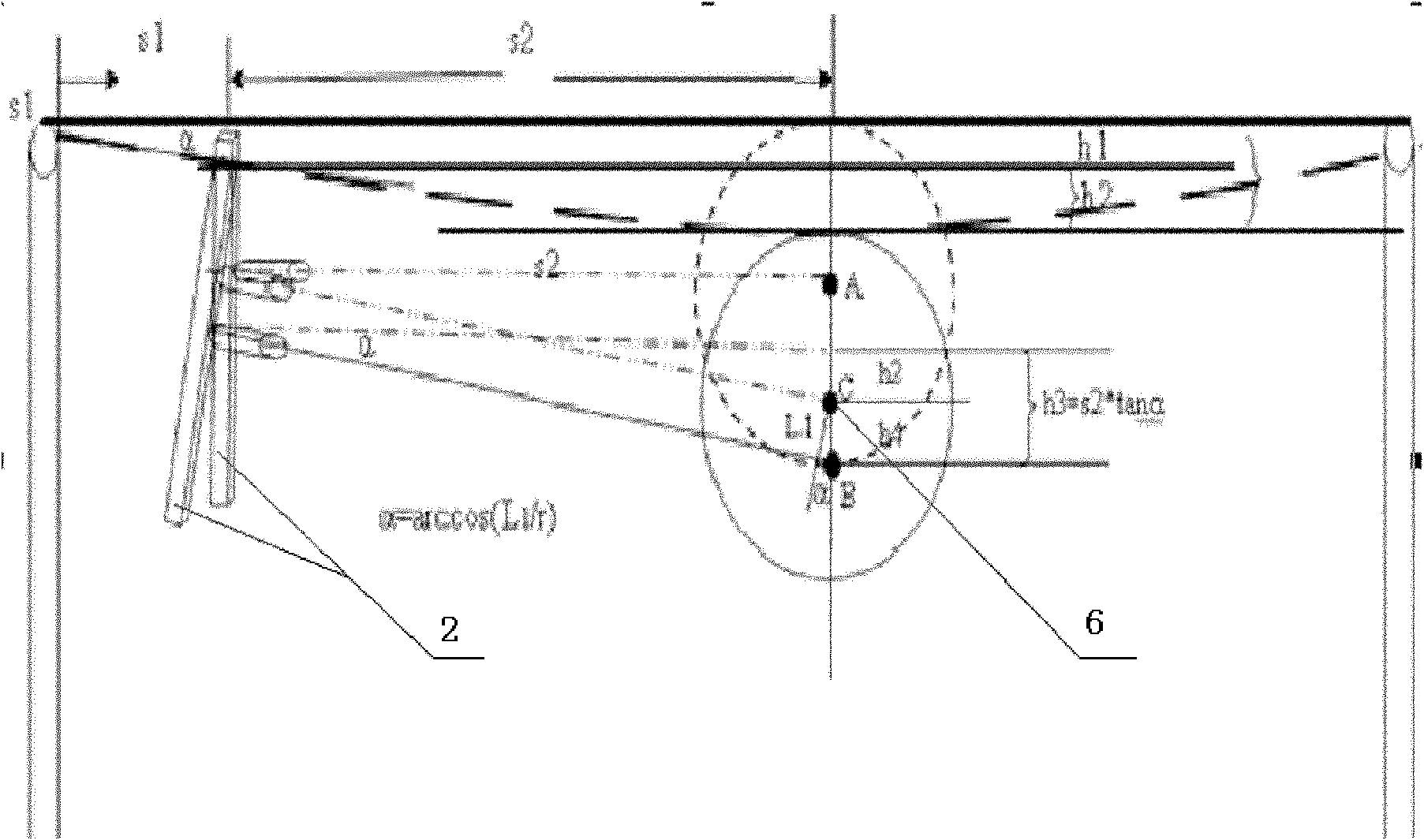

[0042] like image 3 shown. The four-quadrant detector 5 is fixed at the middle position of the bridge 4, and the laser light source 3 is fixed at an appropriate distance from the four-quadrant detector 5 to ensure measurement accuracy. When the deflection of the bridge 4 changes, the deflection value of the point to be measured is H=h1+h2, where h1 is the deflection change value of the electric moving station 2 when the deflection of the bridge 4 changes, and h2 is the four-quadrant detector when the deflection of the bridge 4 changes The change value of the deflection at position 5 relative to position 2 of the electric shift stage. Since there is a certain distance between the electric moving platform 2 and the bridge pier 1, an angle α will be formed between the end point of the bridge 4 and the bridge deck after the deflection of the bridge 4 changes, and an angle α will be formed between the electric moving platform 2 and the original vertical direction; similarly, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com