Early fault search method for large rotary machinery under complicated working conditions

A technology of large-scale rotating machinery and complex working conditions, applied in measuring devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc. Improved accuracy and enhanced security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

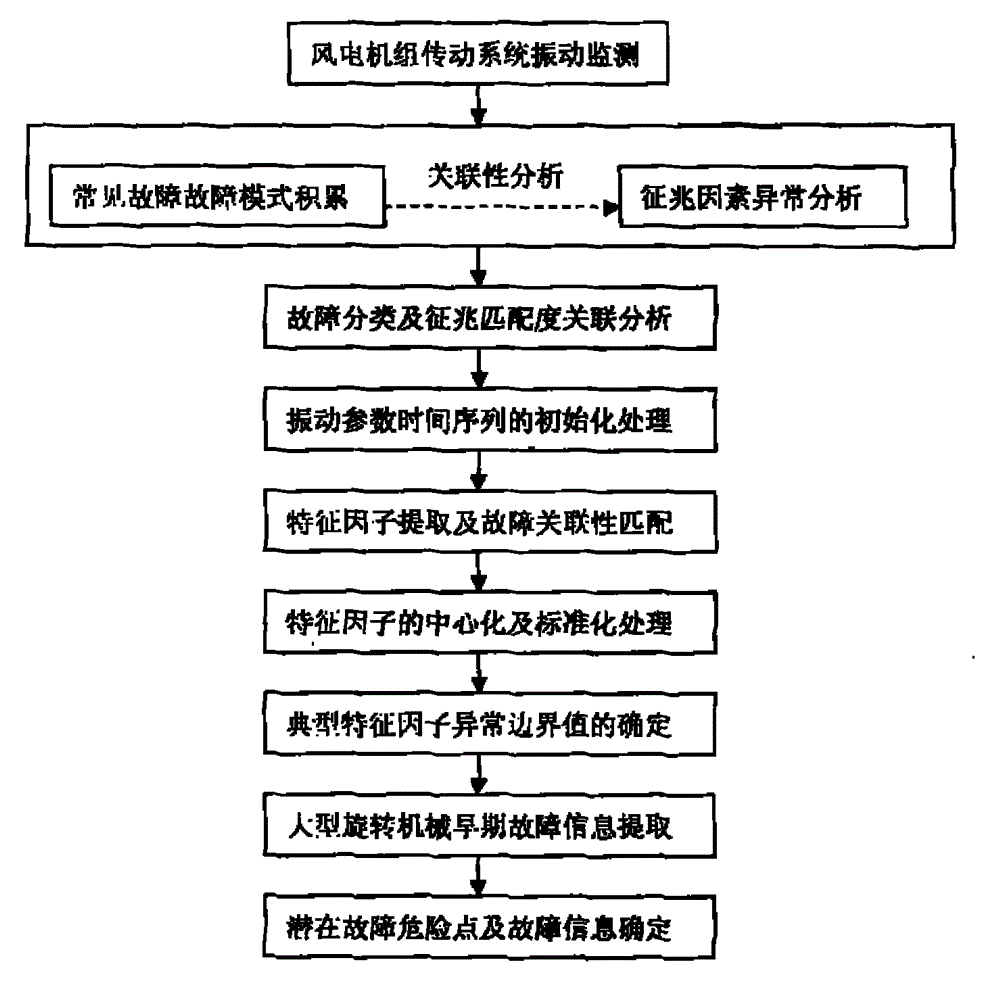

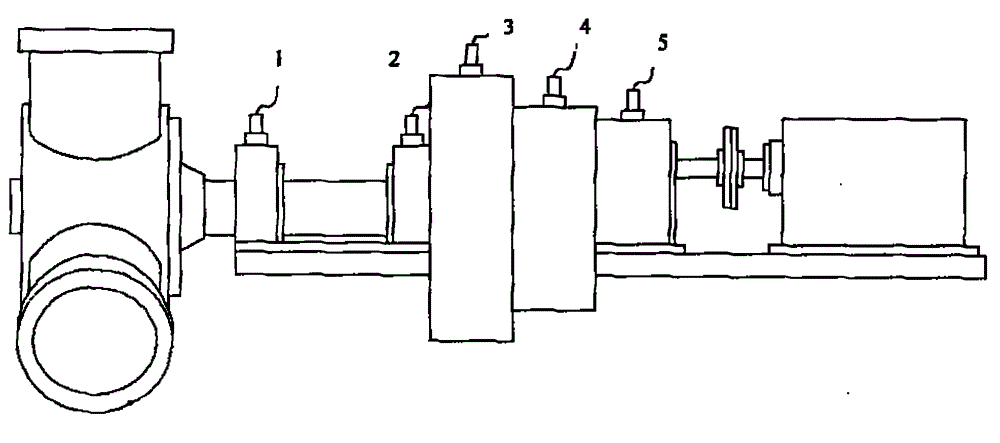

[0026] The invention relates to an early fault search method under complex working conditions of a large rotating machine. The present invention will be described below in conjunction with the accompanying drawings.

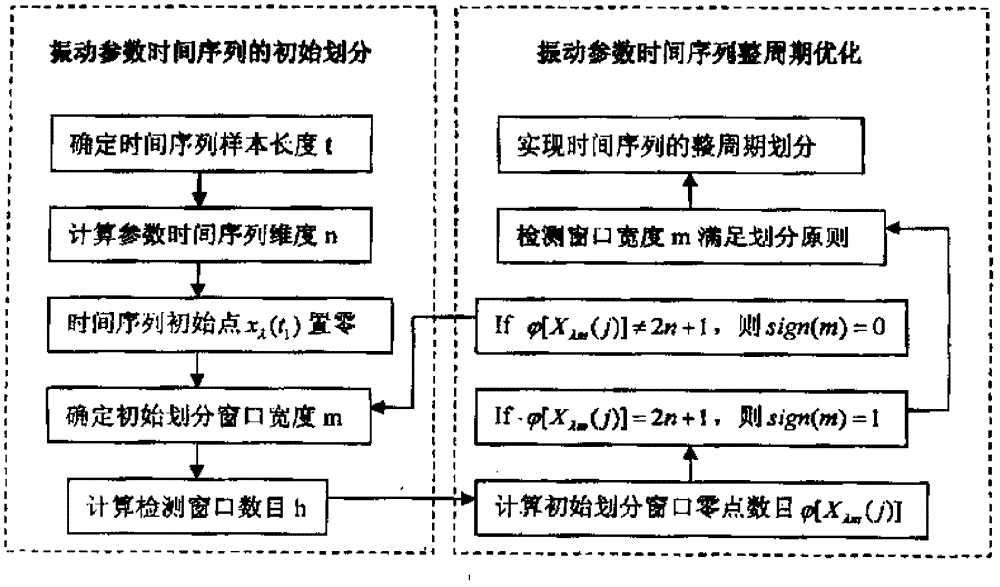

[0027] The vibration parameter data of large rotating machinery is essentially an ordered time series of equipment vibration record values changing with operating time. Changes in equipment operating conditions will inevitably cause corresponding changes in vibration record values and time variables. Changes in equipment operating conditions or potential The occurrence of faults will cause parameter changes. In the actual background, the operation of most large-scale rotating machinery is accompanied by changes in the environment, speed, temperature, pressure and other factors. When we dig out potential operating failures, we need to exclude the abnormalities of equipment monitoring parameters caused by changes in external factors. Interference affects the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com