Dry-mixed mortar mixing plant and station control system

A technology of control system and dry-mixed mortar, which is applied in the field of station control system and dry-mixed mortar mixing building, can solve the problems of poor mortar quality, low degree of automation in the production of mortar mixing stations, and inability to realize automatic control well, etc., to achieve It is convenient for real-time recording and statistics, improving the degree of production automation and eliminating the effect of voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

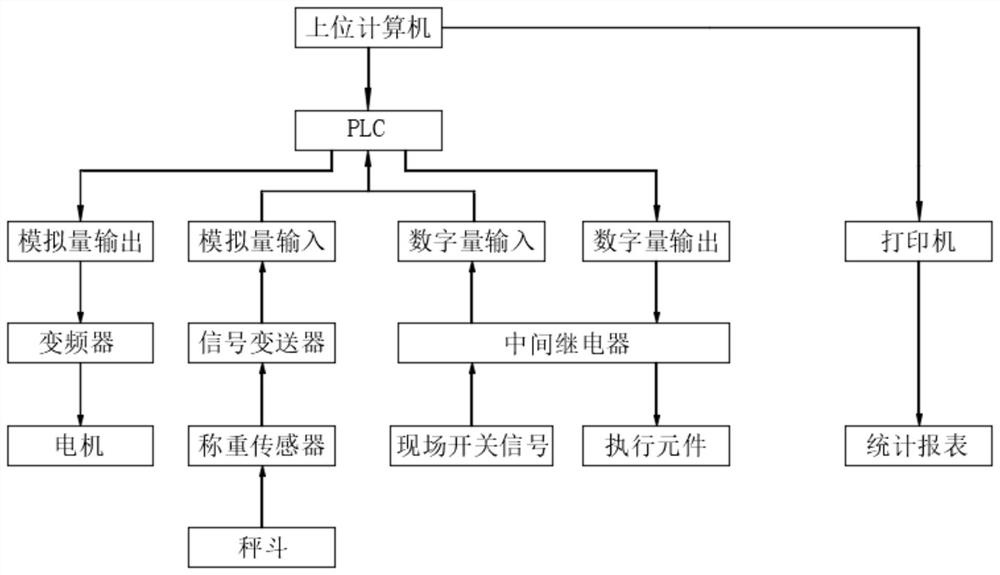

[0024] like figure 1 As shown, a control system for a dry-mixed mortar mixing building and a station includes an operating console, and a host computer is arranged on the console, and the host computer is connected to a PLC, and the PLC includes a CPU module, an analog output module, and an analog input module , digital output module and digital input module;

[0025] The digital output module is connected to the input end of the intermediate relay, and the output end of the intermediate relay is connected to the actuator;

[0026] The digital input module is connected to the output terminal of the intermediate relay, and the intermediate relay collects the switch state signal of each external arc door;

[0027] The analog output module is connected to a frequency converter, and the frequency converter is connected to a motor;

[0028] The analog input module is connected with the output end of the load cell.

[0029] The digital output module in the PLC realizes the openin...

Embodiment 2

[0032] This embodiment is based on Embodiment 1 to further optimize the description of the present invention.

[0033] like figure 1 As shown, the host computer is connected with a printer; by connecting the printer, statistical reports can be printed at any time, which is convenient for real-time recording and statistics.

[0034] As a preferred manner, a signal transmitter is also connected between the load cell and the analog input module, and the load sensor collects the weight signal and transmits it to the signal transmitter, and the signal transmitter is integrated After the signal is amplified, it enters the analog input module to realize the collection of weight.

[0035] The weighing sensor collects the external weighing analog signal, and the weighing sensor transmits the weighing analog signal to the signal transmitter, and the signal transmitter enters the analog input module of PLC after integrating and amplifying the signal to realize the weight collection; It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com