Main transformer oil conservator state prediction method and device based on digital twinning and electronic equipment

An oil pillow and twin technology, which is applied in the state prediction of main transformer oil pillow based on digital twin, in the field of electronic equipment, can solve problems such as temperature rise, maintenance difficulty, inability to predict the health status of equipment, etc., to ensure reliability. , the effect of avoiding serious failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

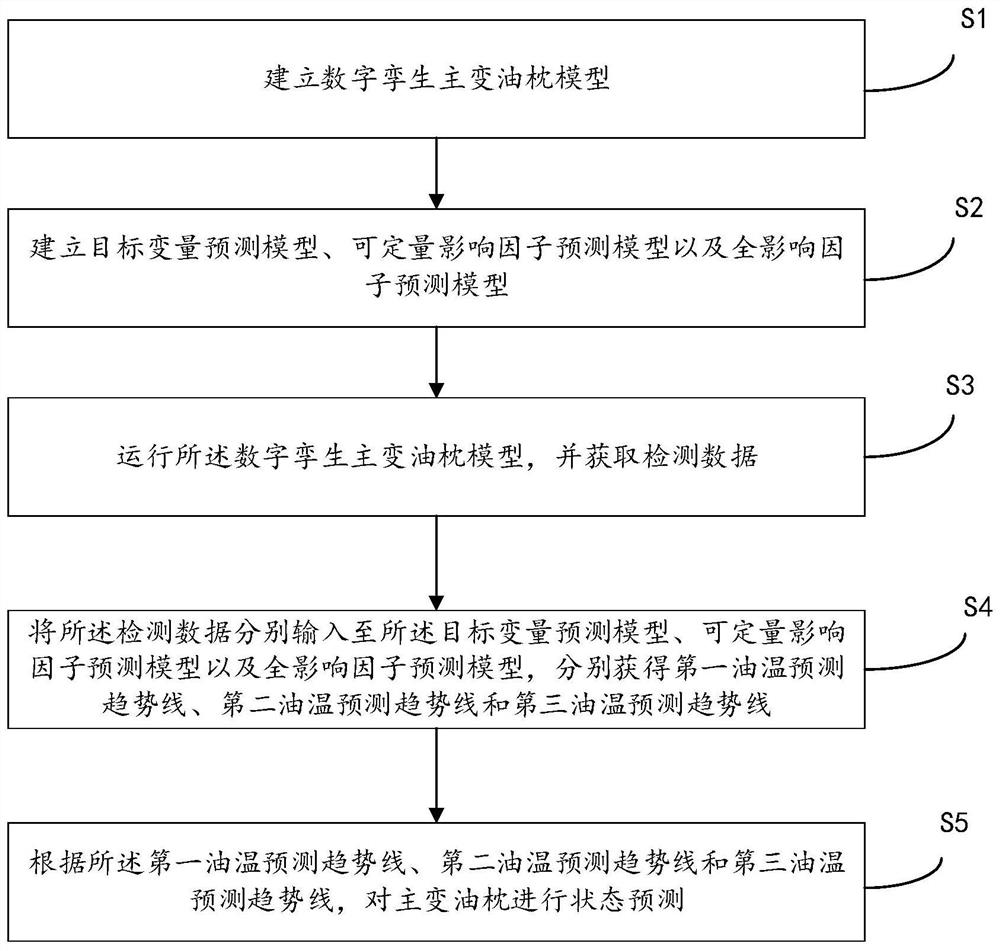

[0051] refer to figure 1 , this embodiment provides a method for predicting the state of the main transformer oil conservator based on digital twins, including:

[0052] S1. Establish a digital twin main transformer oil conservator model;

[0053]S2. Establish a target variable prediction model, a quantifiable impact factor prediction model, and a full impact factor prediction model;

[0054] S3. Run the digital twin main transformer oil conservator model, and obtain detection data;

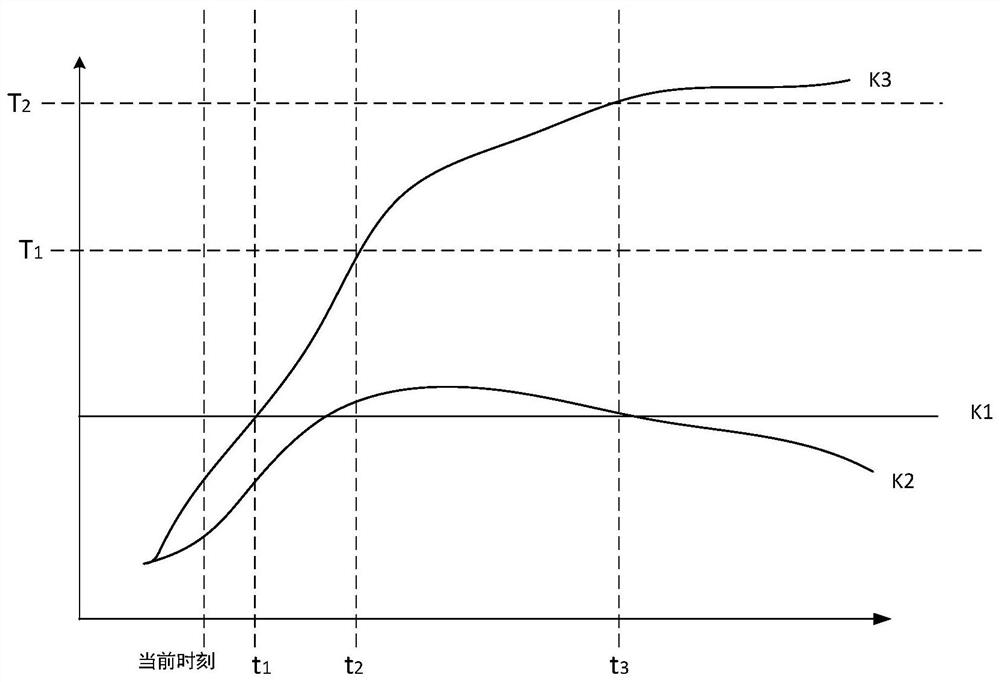

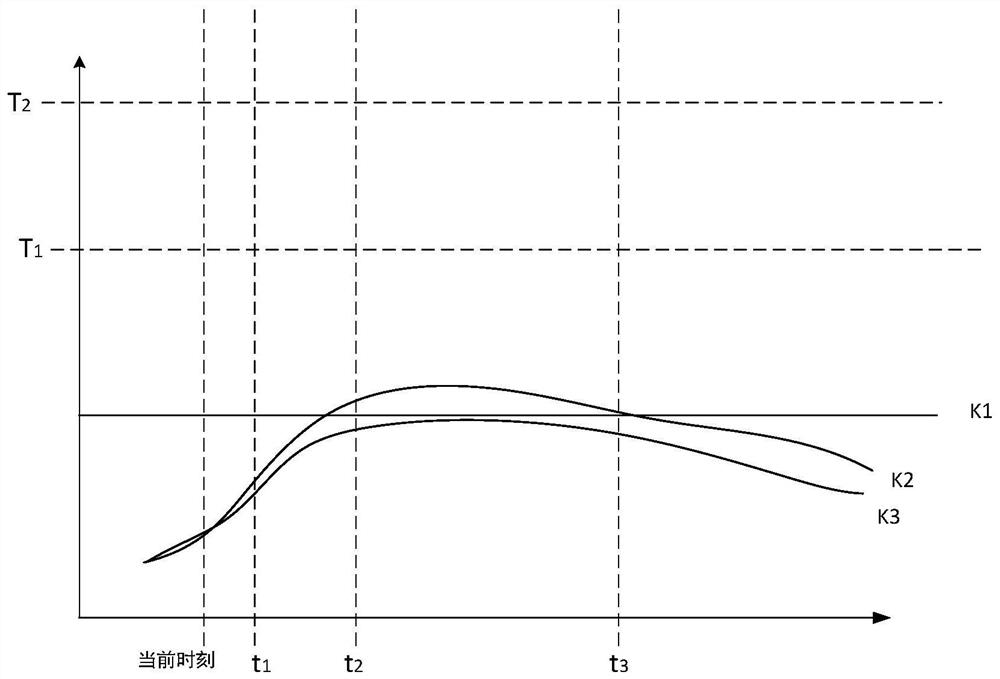

[0055] S4. Input the detection data into the target variable prediction model, the quantifiable influencing factor prediction model and the full influencing factor prediction model respectively, and obtain the first oil temperature prediction trend line, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com