Method and system for automatically controlling synchronous action of filter plates of filter press

A filter press filter plate, synchronous action technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

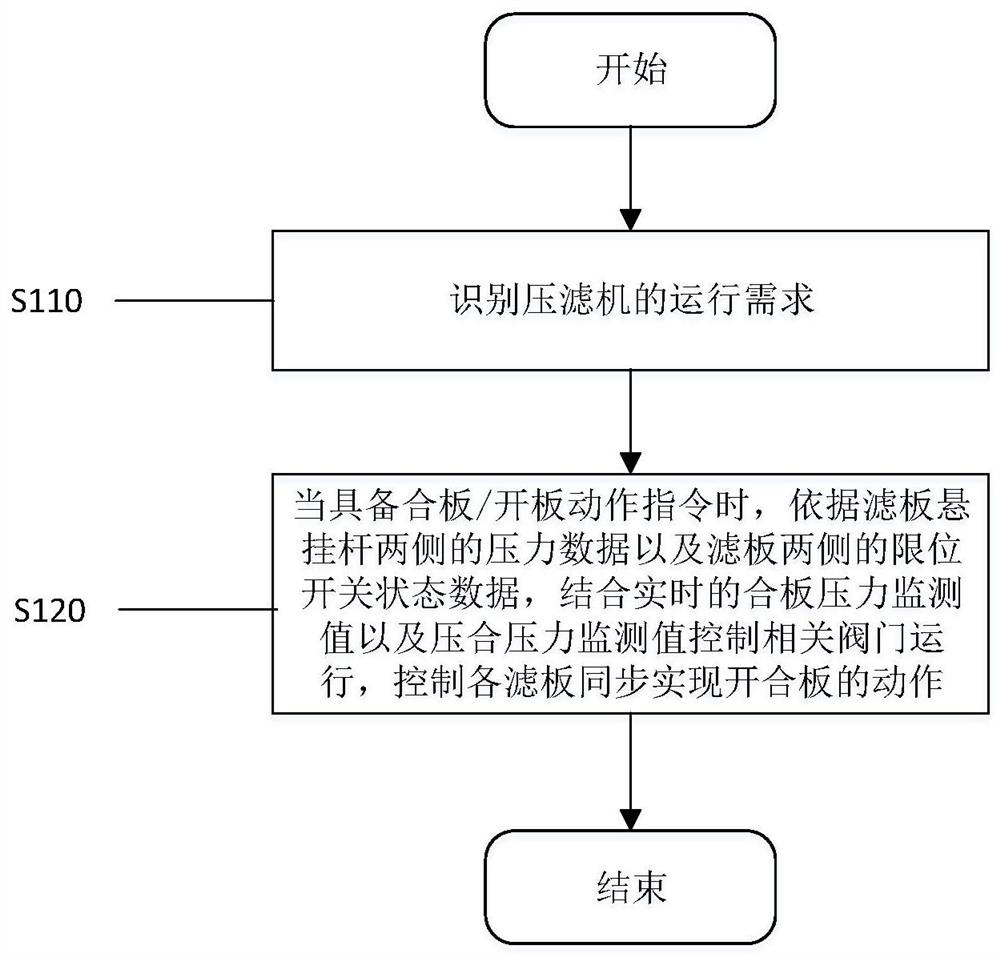

[0056] figure 1 It shows a schematic flow chart of the method for automatically controlling the synchronous action of the filter plate of the filter press provided by Embodiment 1 of the present invention, refer to figure 1 As can be seen, the method includes the following steps:

[0057] S110. Identify the operation instruction of the filter press. This step is to determine whether the current filter press has a control command to execute the action, and what action process needs to be automatically executed. After the action to be executed is identified as the process of opening and closing the plate, the method or step in S120 is further executed.

[0058] This operation can ensure that the synchronous action of the opening and closing plate of the filter press is carried out under the premise of having the action command, and having the corresponding opening and closing plate action command indicates that the current filter press system and the various valves and structur...

Embodiment 2

[0125] In consideration of other aspects of any one or more of the above embodiments, the present invention further provides a system for automatically controlling the synchronous action of filter plates of a filter press. The system executes the methods or steps described in any one or more embodiments above. Figure 4 A schematic structural diagram of a system for automatically controlling the synchronous action of filter plates of a filter press in an embodiment of the present invention is shown, and the following is combined with Figure 4 The information in describes the structure of the system.

[0126] An operation instruction identification module 41 configured to identify an operation instruction of the filter press. This step is to determine whether the current filter press has a control command to execute the action, and what kind of action process needs to be automatically executed. After identifying and determining the action to be executed as the opening and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com