Energy method-based high-temperature radiation rate measuring device of semi-transparent material and revising method for deducting background radiation

A translucent material, high-temperature radiation technology, applied in measuring devices, optical radiation measurement, radiation pyrometry, etc., can solve the problems of low measurement accuracy, large background radiation noise, and low temperature upper limit of emissivity measurement technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

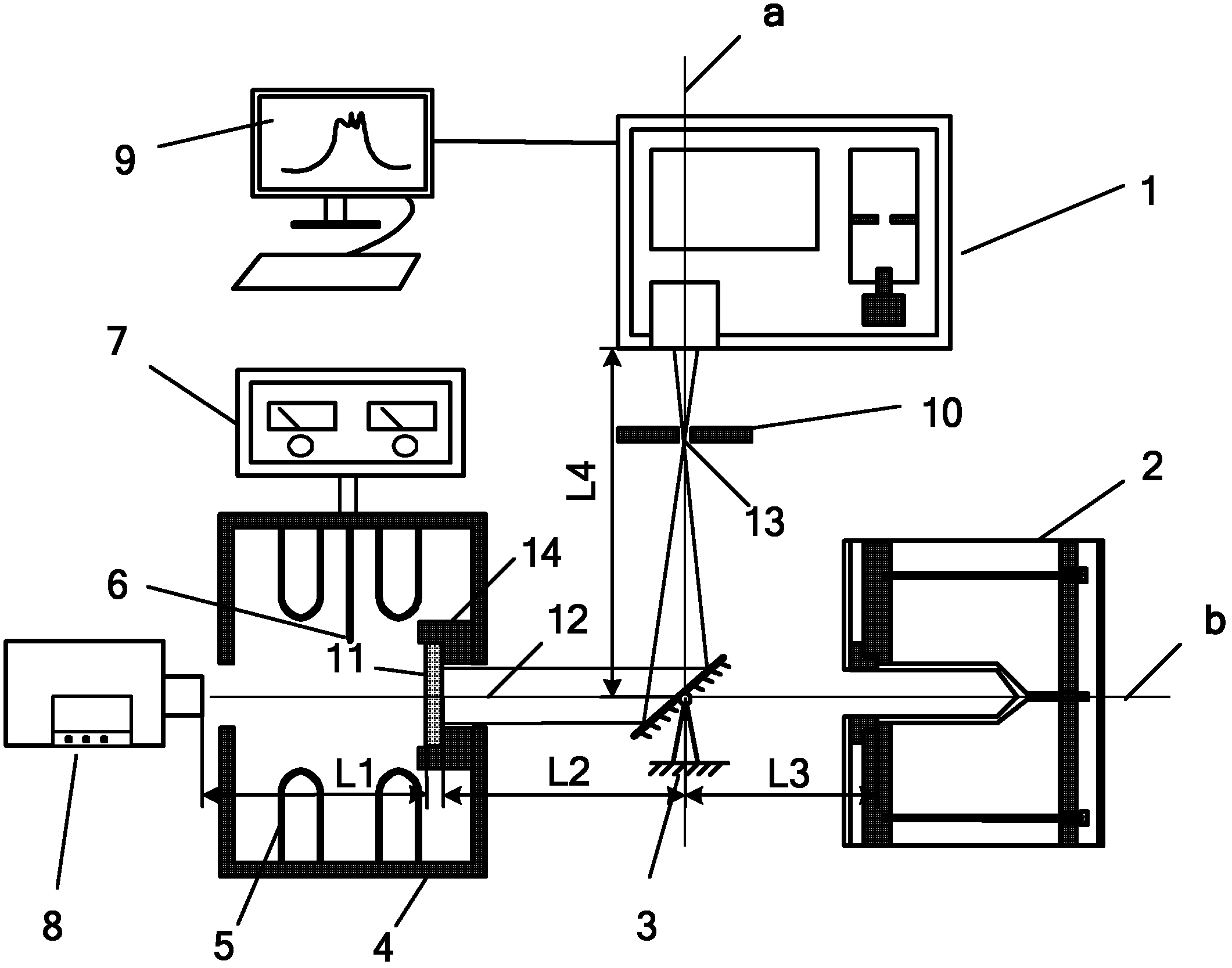

[0066] Specific implementation mode one: the following combination figure 1 This embodiment will be described.

[0067] A device for measuring high-temperature emissivity of translucent materials based on an energy method, characterized in that it includes a Fourier infrared spectrum analyzer 1, a reference blackbody furnace 2, a rotatable mirror 3, a heating furnace 4, a heater 5, and a temperature acquisition device 6. Temperature inspection controller 7, incident light source 8, data processing system 9 and aperture 10;

[0068] Described heating furnace 4 is built-in light-transmitting port 12, the fixing device 14 of translucent test piece and the temperature collecting device 6; Light-transmitting port 12; the temperature signal output end of the temperature acquisition device 6 is connected to the temperature signal input end of the temperature inspection control instrument 7, and the output end of the temperature control signal of the temperature inspection control in...

specific Embodiment approach 2

[0096] Specific implementation mode two: a correction method for subtracting background radiation of a translucent material high-temperature emissivity measuring device based on an energy method, characterized in that the steps of realization are:

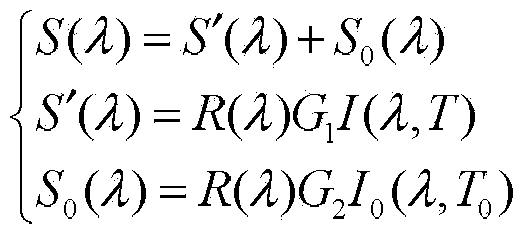

[0097] Step 1. Start the reference blackbody furnace 2, and adjust the collimation of the optical path, measure the spectral radiation signal distribution of the reference blackbody furnace 2 at two different temperatures, and then determine the Fourier infrared spectrum analyzer according to the ambient radiation compensation algorithm for removing background noise. The response function between the input signal and the output signal of 1; the specific method is:

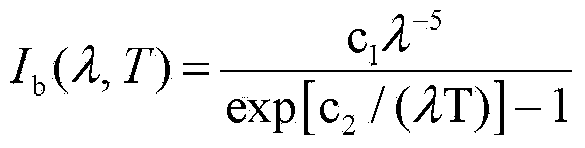

[0098] The expression of the radiation signal measurement output of the Fourier infrared spectrometer 1 at the wavelength λ is:

[0099] S ( λ ) ...

specific Embodiment approach 3

[0140]Specific Embodiment Three: This embodiment is a further description of Embodiment Two.

[0141] A correction method for subtracting background radiation of a translucent material high-temperature emissivity measuring device based on an energy method. The size of the translucent test piece 11 is: the diameter of the circular test piece is 25-100mm, and the side length of the rectangular test piece is 25-100mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com