Detection method of LED (light-emitting diode) lamp array

A detection method and technology of LED lights, applied in the field of LED light array detection, can solve the problems of poor continuous welding of LED light arrays and achieve 100% effective detection, and achieve the goals of less visual fatigue, convenient detection of false welding, and convenient continuous welding detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

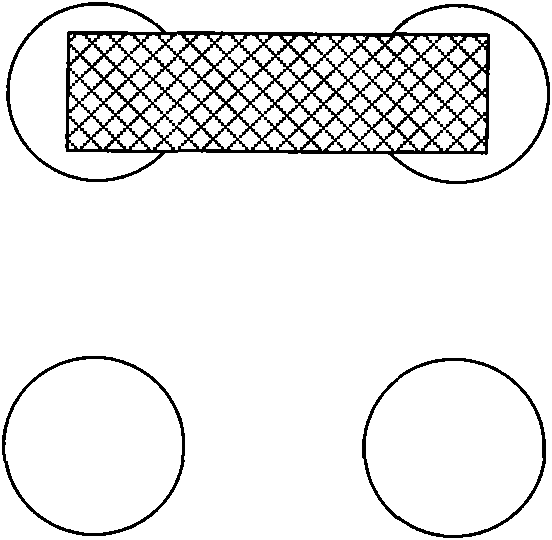

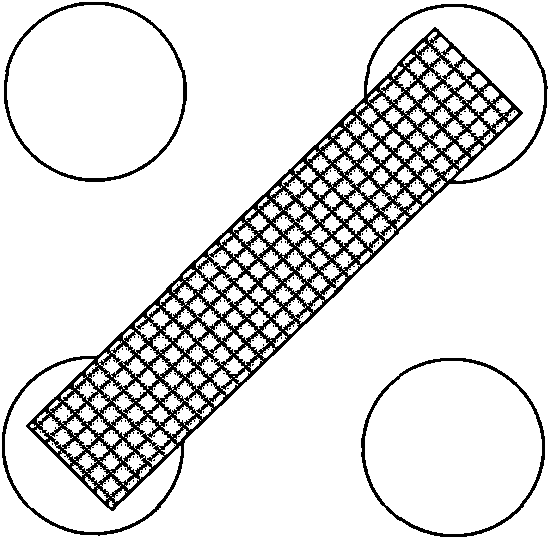

[0021] When there is poor connection between various pins on the driver chip of the LED light array, there may be two continuous welding states: figure 1 Adjacent bonding as shown, that is, bonding occurs between two laterally or vertically adjacent leads; and, if figure 2 The diagonal joint welding shown is that the joint welding occurs between two adjacent pins along the diagonal direction.

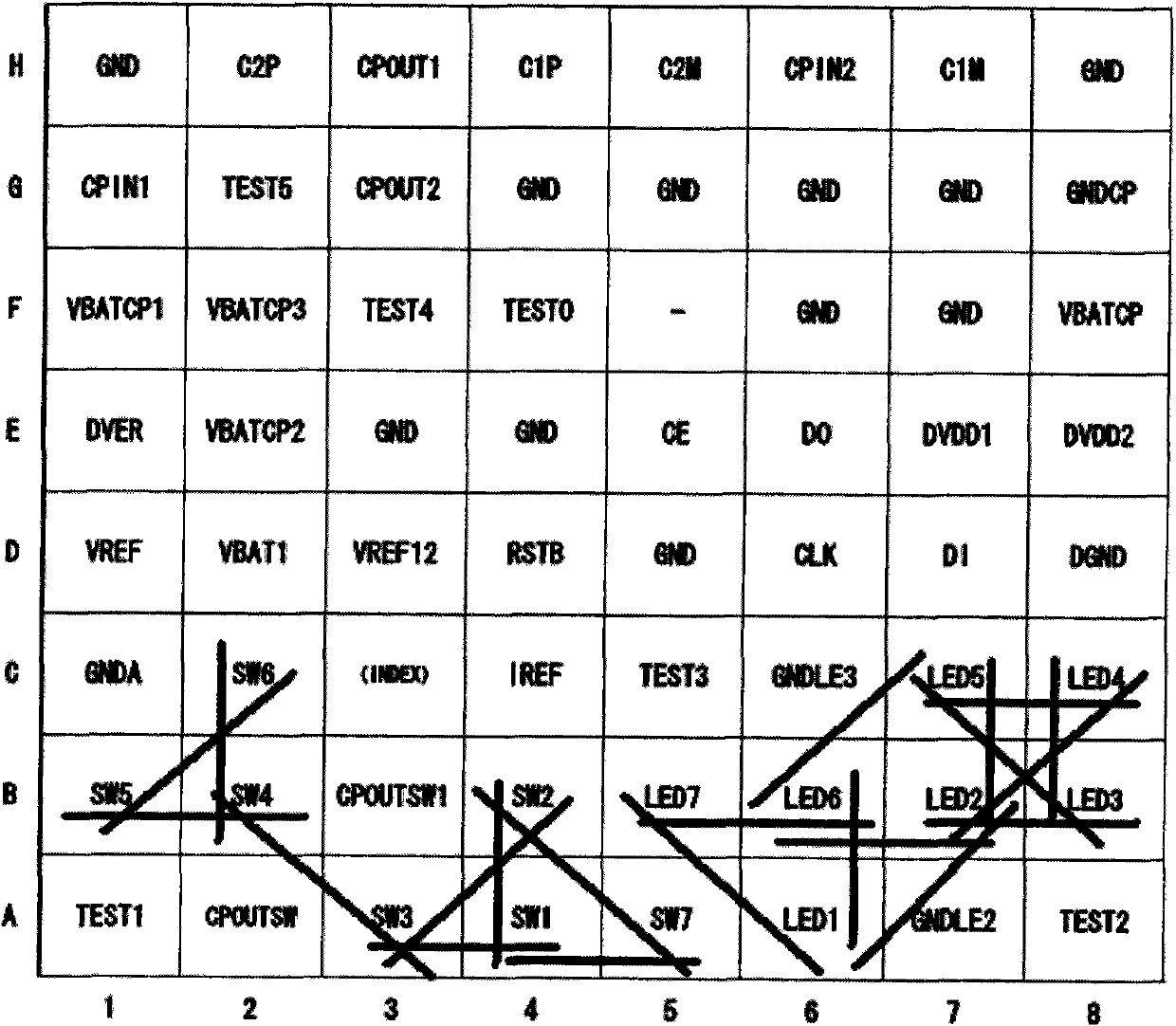

[0022] Through the functional analysis of various pins, it can be seen that only the welding between the driving pins of the LED (including the positive pin and the negative pin) will be reflected in the display state of the LED light array, and the LED The welding connection between the driving pin and other functional pins can be effectively detected in other existing functional testing proced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com