Leveling device for light-emitting diode (LED) supports

A technology of LED brackets and leveling devices, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing labor costs, floor space, and product damage efficiency, so as to reduce labor costs and floor space, and avoid product damage. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

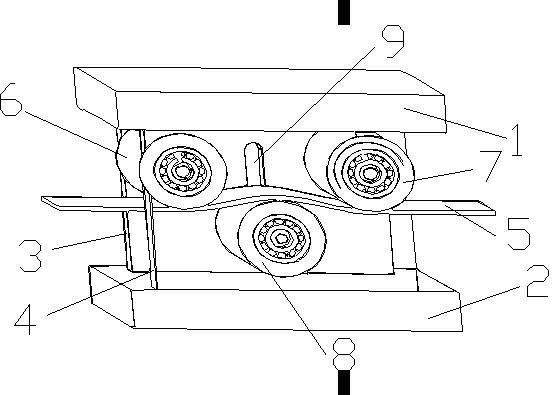

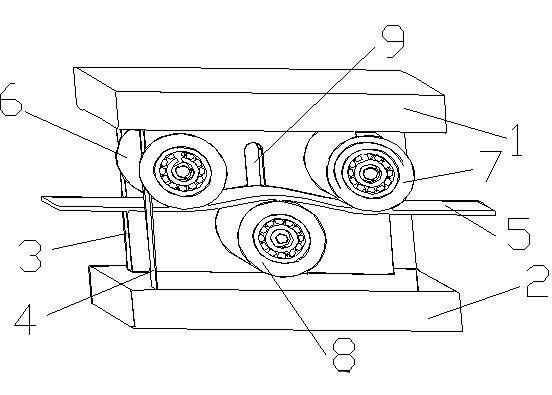

[0012] like figure 1 As shown, a LED bracket leveling device includes an upper base plate 1 and a lower base plate 2, a first support plate 3 and a second support plate 4 are installed between the upper base plate 1 and the lower base plate 2, and the first support plate 3 Three scroll wheels are installed between the second support plate 4, wherein the first scroll wheel 6 and the second scroll wheel 7 are installed at the same height, and the first support plate 3 and the second support plate 4 are provided with shapes, heights Corresponding to the groove 9, both ends of the third scroll wheel 8 are installed in the groove 9, and the position of the third scroll wheel 8 can be adjusted up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com