Tool for placing a joint in a leaf rebate of a vehicle

A joint body and tool technology, applied in the manufacture of tools, vehicle parts, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

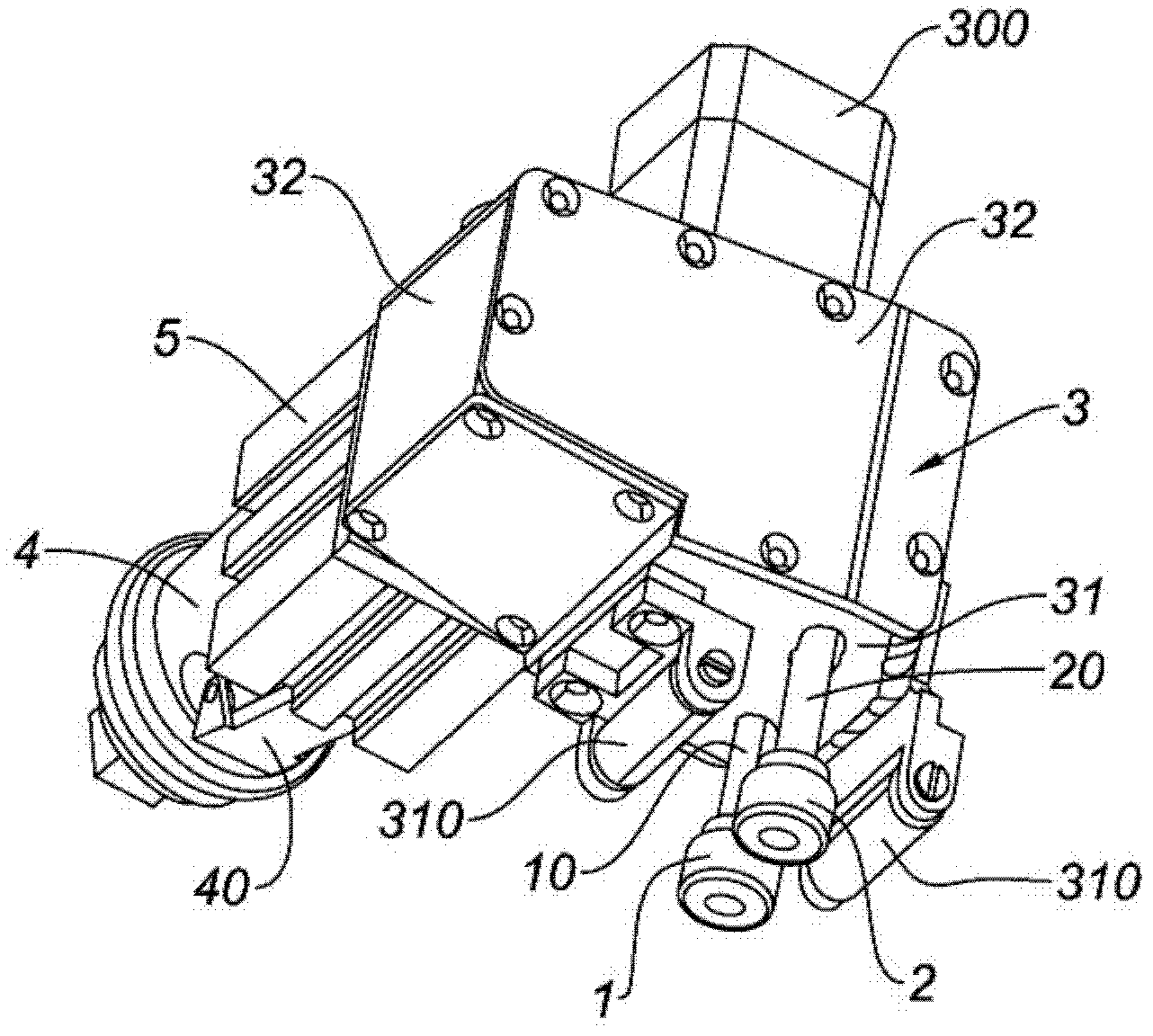

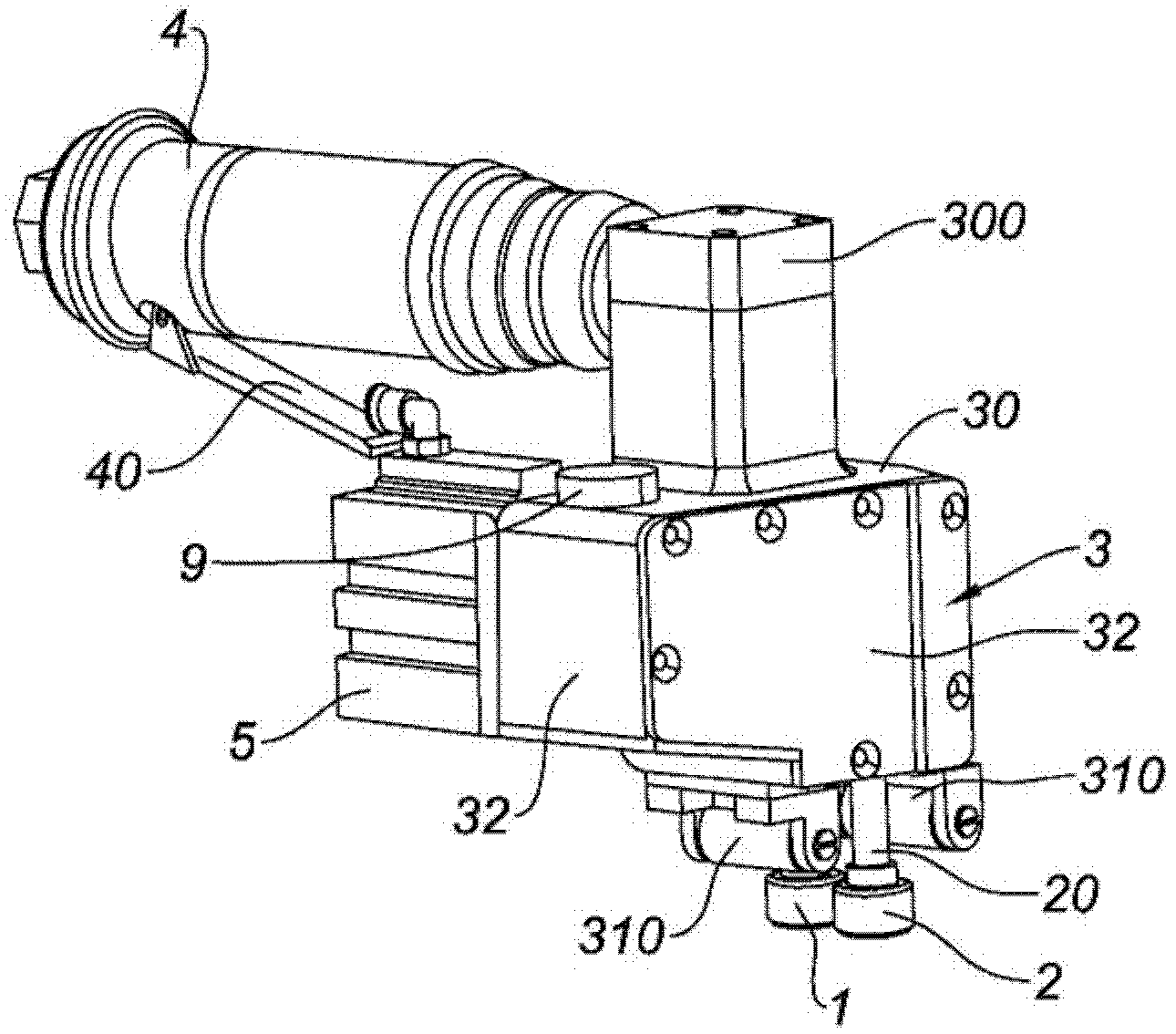

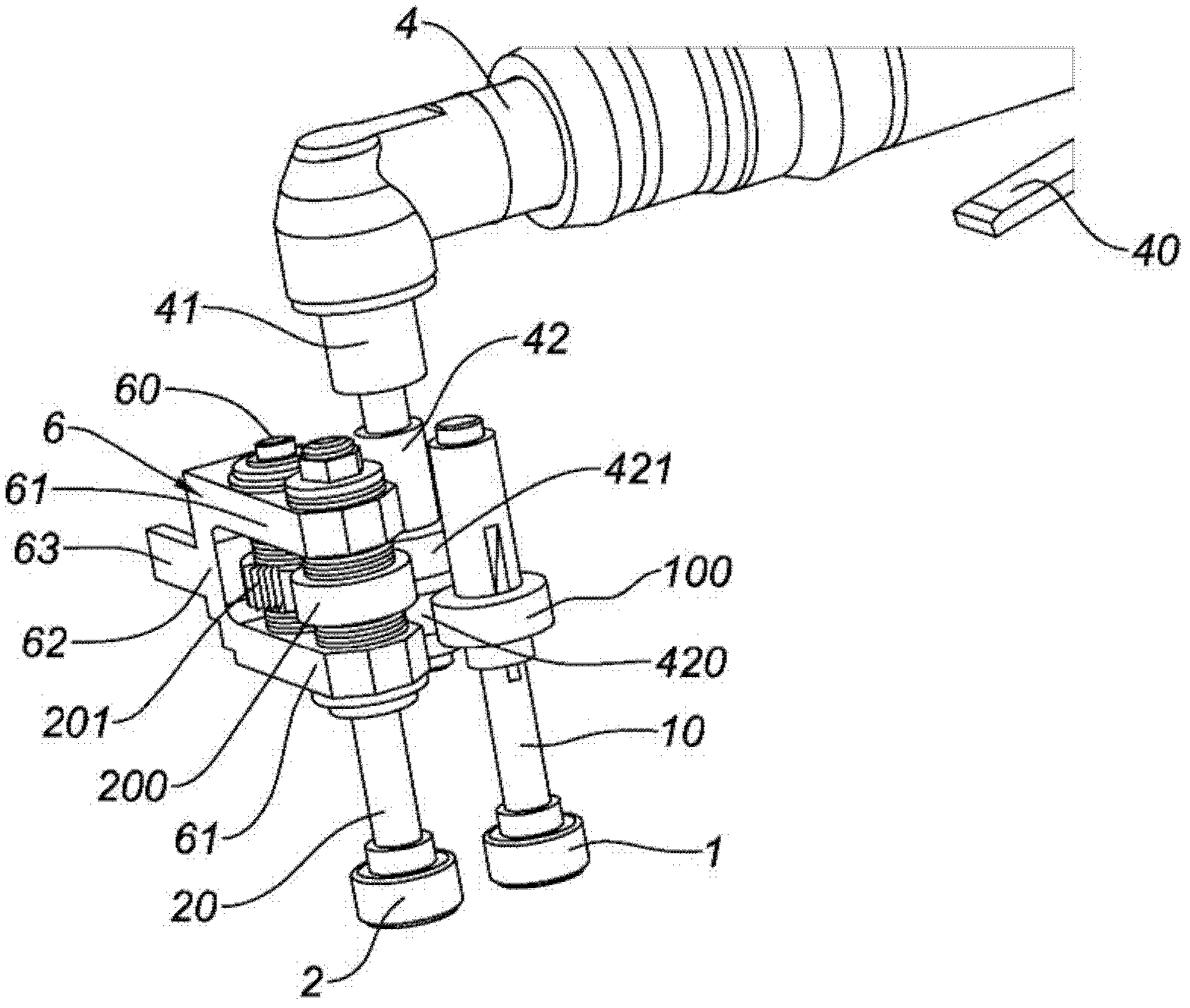

[0041] Figures 1 to 5 The illustrated tool comprises a first roller 1 and a second roller 2 , rotatably mounted and fastened respectively on first and second substantially parallel axes 10 and 20 .

[0042] The tool has a substantially parallelepiped-shaped tool body 3 . The body 3 comprises an upper surface 30 and a lower surface 31 connected to each other with four lateral surfaces 32 . Obtained from the perspective view, the lower surface 31 (the corresponding upper surface 30) and the two lateral surfaces 32 are in figure 1 in (correspondingly in figure 2 ) is visible.

[0043] The upper surface 30 is equipped with a fixed housing 300 of the pneumatic screwdriver 4 . Housing 300 is connected with screwdriver 4 in figure 2 more clearly visible in . Furthermore, the screwdriver 4 is provided with a lever 40 designed to control it.

[0044] The lower surface 31 is itself equipped with two mounted idler wheels 310 , arranged in a symmetrical manner on each side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com