Vehicle body rear structure

A technology for the rear part and structure of the car body, which is applied in the field of improvement of the rear part structure of the car body, and can solve problems such as increasing the number of parts and increasing the weight of rigid parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

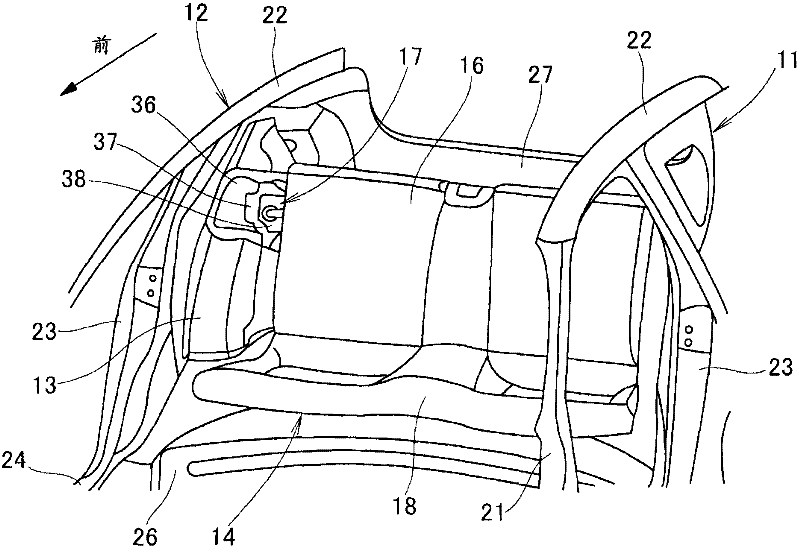

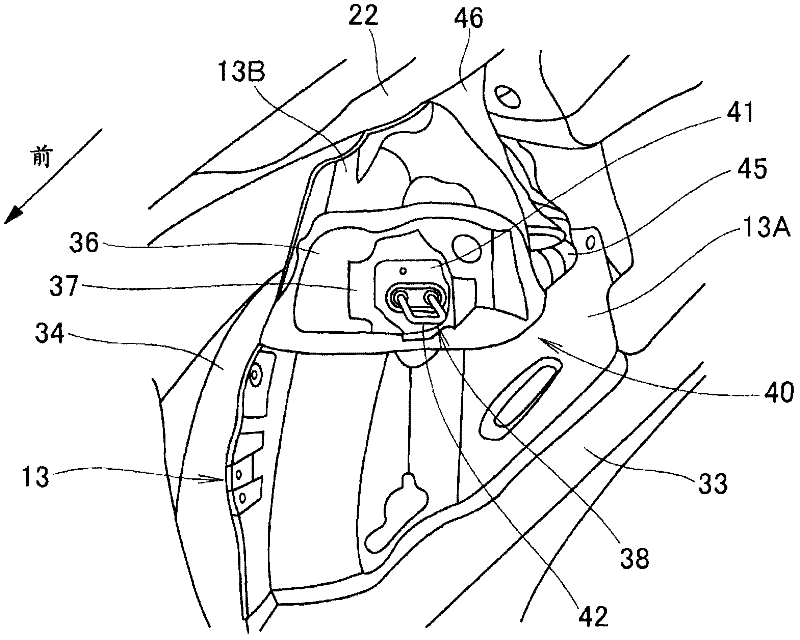

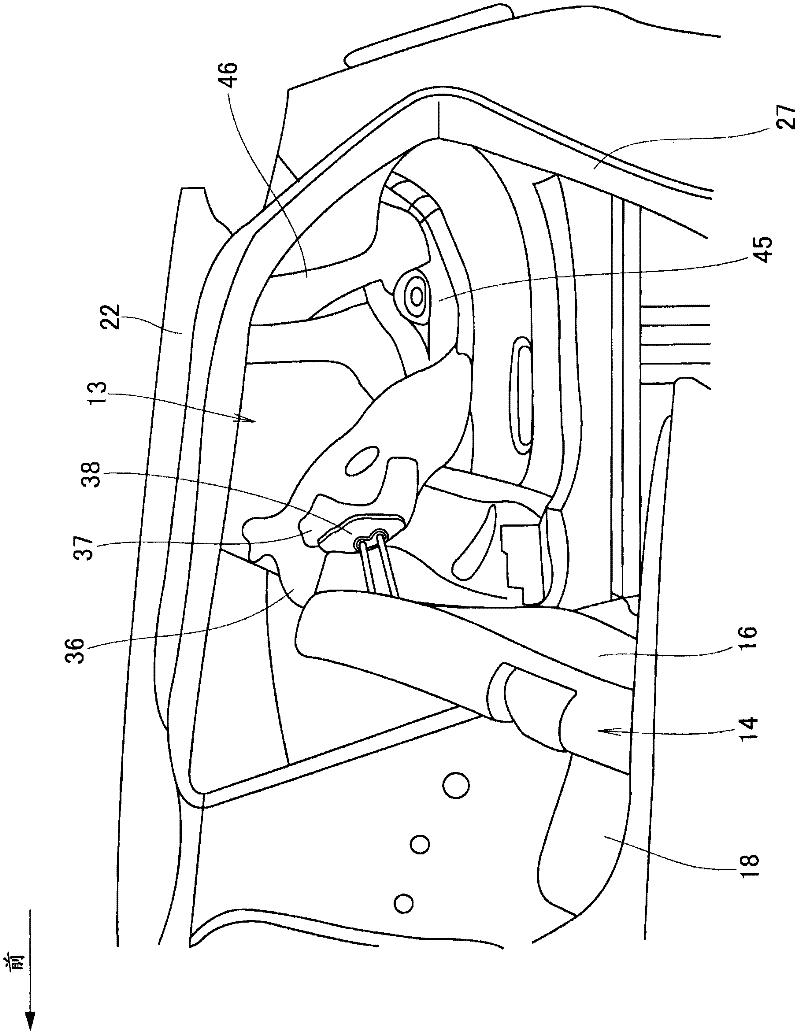

[0031] Such as figure 1 As shown, a rear wheelhouse inner panel 13 (only one reference numeral 13 is shown) is provided at each rear portion of a left vehicle body 11 and a right side vehicle body 12 constituting the vehicle body. The rear seat 14 is composed of a foldable seat back 16 and a seat cushion 18 . The seat back 16 is swingably attached to the rear end of the seat cushion 18 . Each rear wheelhouse inner panel 13 and the seat back 16 are detachably engaged via an engaging device 17 .

[0032] Left and right roof side rails 22 extend rearward from upper ends of left and right front pillars 21 (only one of which is shown in the figure). The left and right center pillars 23 extend downward from the middle portions of the left and right roof side rails 22 in the vehicle front-rear direction. The left and right side sills 24 (only one is shown in the figure) support the lower end of the center pillar 23 . The mid-floor cross member 26 connects the left and right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com