Symmetrical opposite three-dimensional circular-flow integration oxidation ditch

A technology of three-dimensional circulation and oxidation ditch, applied in chemical instruments and methods, multi-stage water/sewage treatment, sustainable biological treatment, etc., can solve problems such as increasing equipment costs, increasing construction and installation costs, and affecting denitrification effects, achieving Strong ability to resist impact load, solve the problem of small single ditch volume, and improve the denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

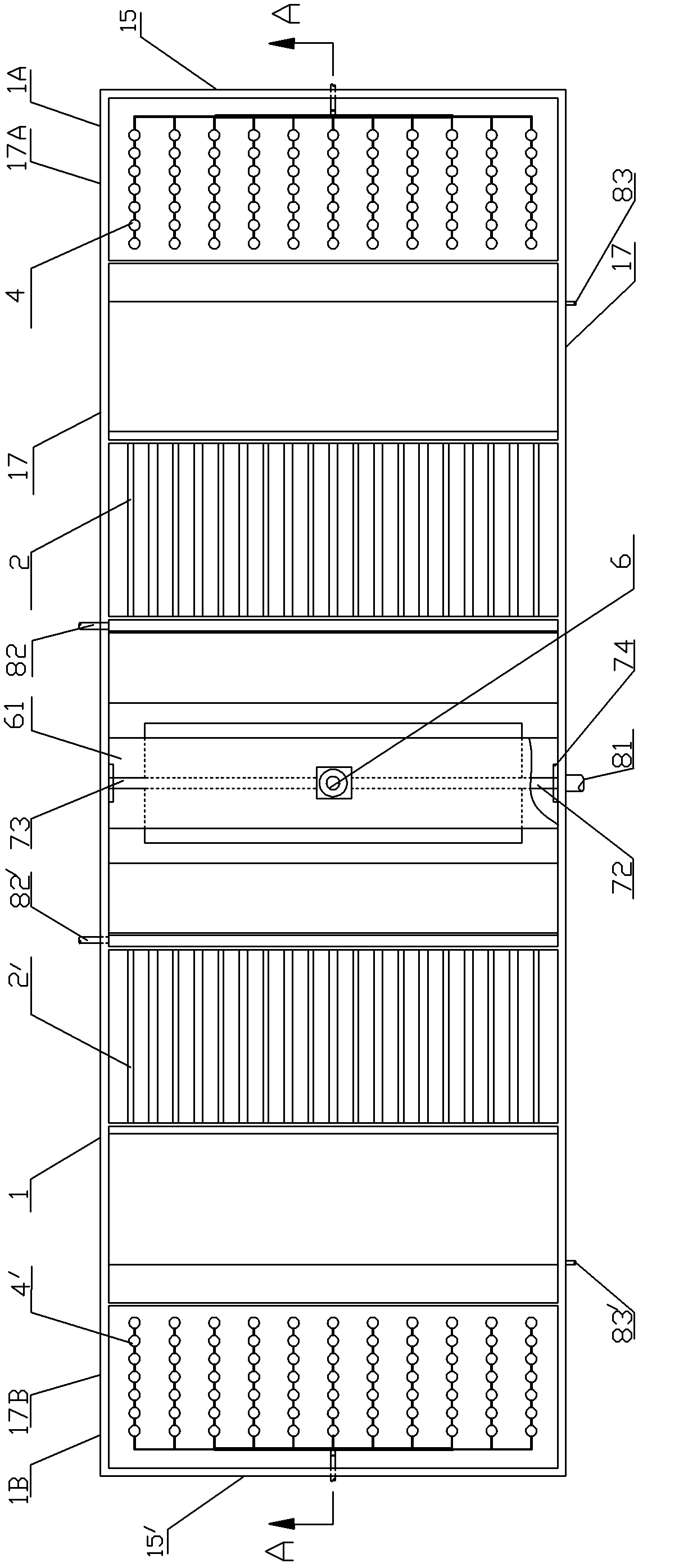

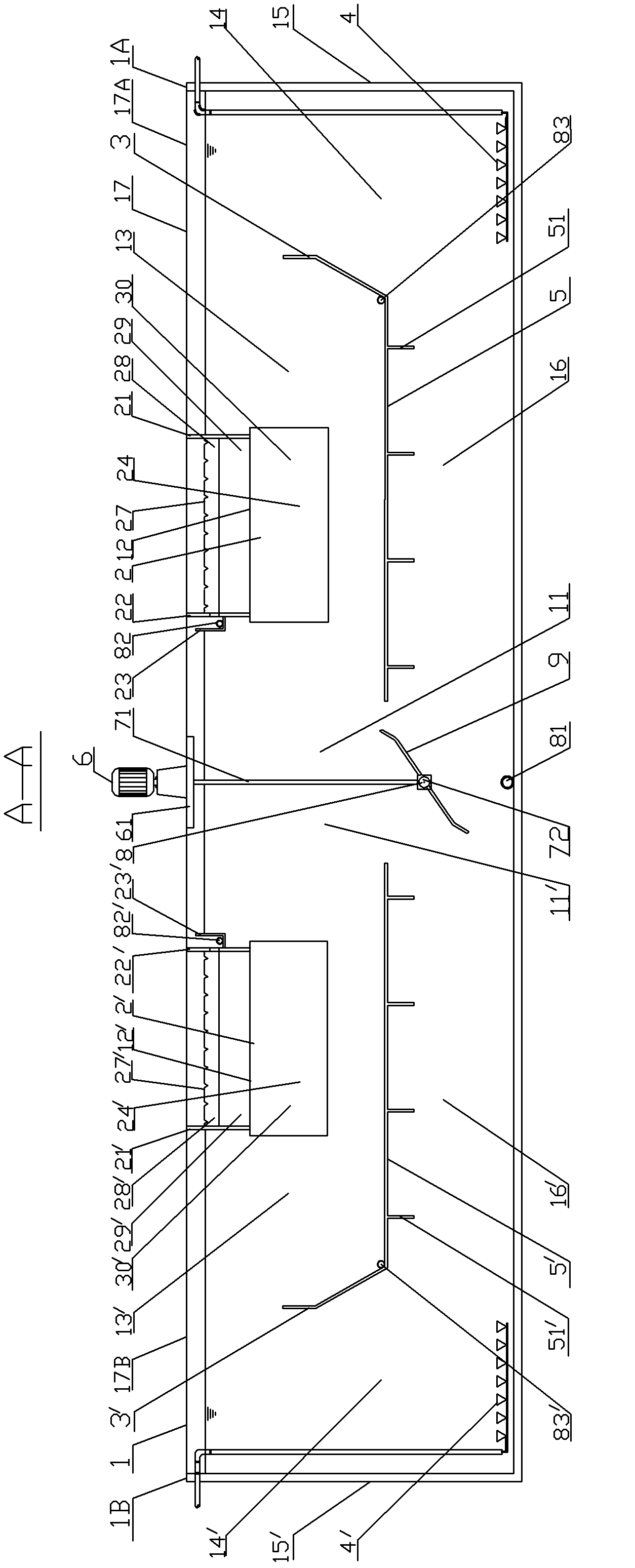

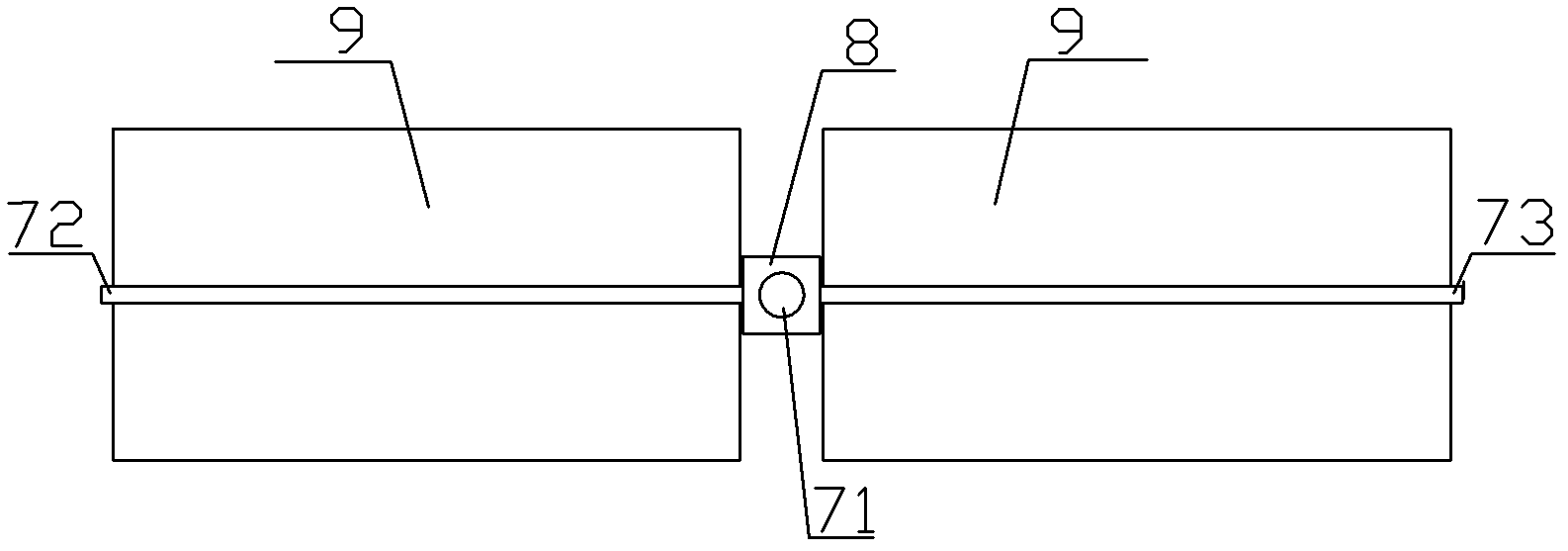

[0017] Figure 1 ~ Figure 4It shows a symmetrical opposite three-dimensional circulating flow integrated oxidation ditch and its local structure, including an air-lifting plug-flow three-dimensional circulating oxidation ditch 1A, in which an air-lifting aerobic zone 14, an aerobic zone 13, The solid-liquid separation zone 12, the transition anoxic zone 11, and the anoxic zone 16 are provided with horizontal partitions 5 that divide the trench body into upper and lower layers of channels in the middle and lower part of the trench body. The above-mentioned aerobic zone 13 is located in In the upper channel, the above-mentioned anoxic zone 16 is set in the lower channel; one end of the horizontal partition 5 is connected to the inclined diversion wall 3 extending obliquely upward to its outer side and the top is a vertical end wall, and the above-mentioned air-lift aerobic zone 14 is set Between the inclined diversion wall 3 and the end wall 15 of the ditch body, a microporous a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap