Pulse type fluid mixing diaphragm pump and mixing ratio design method thereof

A fluid mixing and design method technology, which is applied to the components of pumping devices for elastic fluids, variable displacement pump components, pumps, etc., can solve the problem of increasing volume and manufacturing cost, affecting product quality experience, and noise interference. and other problems, to achieve the effect of increasing the air-water mixing function, the best flushing effect, and reducing the noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

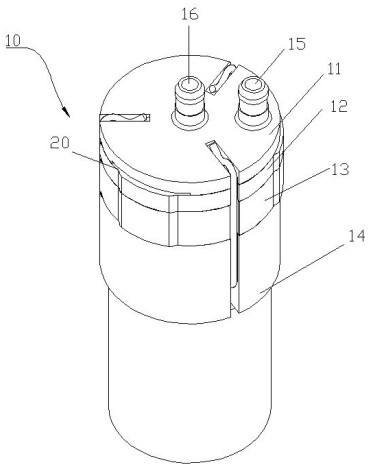

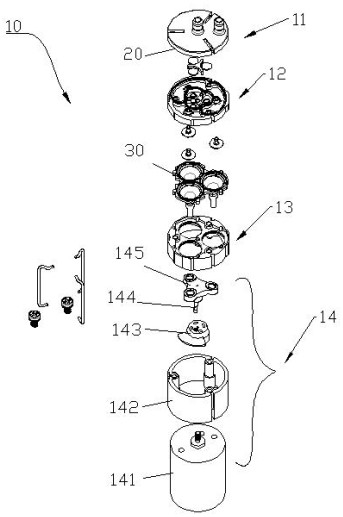

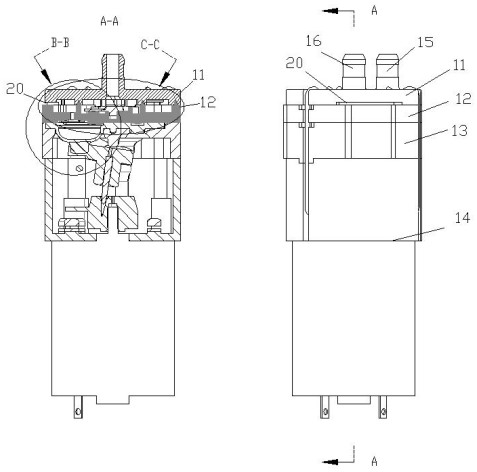

[0045] The present invention is further described below in conjunction with the accompanying drawings and specific embodiments.

[0046] as Figures 1 to 9 Diaphragm pump shown, a pulsed fluid mixed diaphragm pump, comprising a cover plate 11, valve seat 12, diaphragm seat 13 and a drive mechanism 14, a diaphragm seat 13 is evenly distributed on the diaphragm 30, the drive mechanism 14 drives the diaphragm 30 circular reciprocating motion, several diaphragm sac sequentially compresses and stretches the diaphragm sac to aspirate fluid, the diaphragm 30 includes more than one first diaphragm sac 301 for the first fluid aspiration and more than one second diaphragm sac 302 for the suction of the second fluid, Cover plate 11 and valve seat 12 is provided with a card slot in conjunction with the sealing into an outlet channel cavity 21 and an inlet channel cavity 22.

[0047] as Figure 4As shown, the missing groove 20 is provided at the peripheral junction between the cover plate 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com