Multistage self circulation anaerobic digestion reactor and work method thereof

An anaerobic digestion and reactor technology, applied in anaerobic digestion treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve the problem of low rising flow rate, low reactor efficiency and low mass transfer efficiency of anaerobic digestion reactor and other problems, to achieve the effect of superior mass transfer effect, good controllability and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

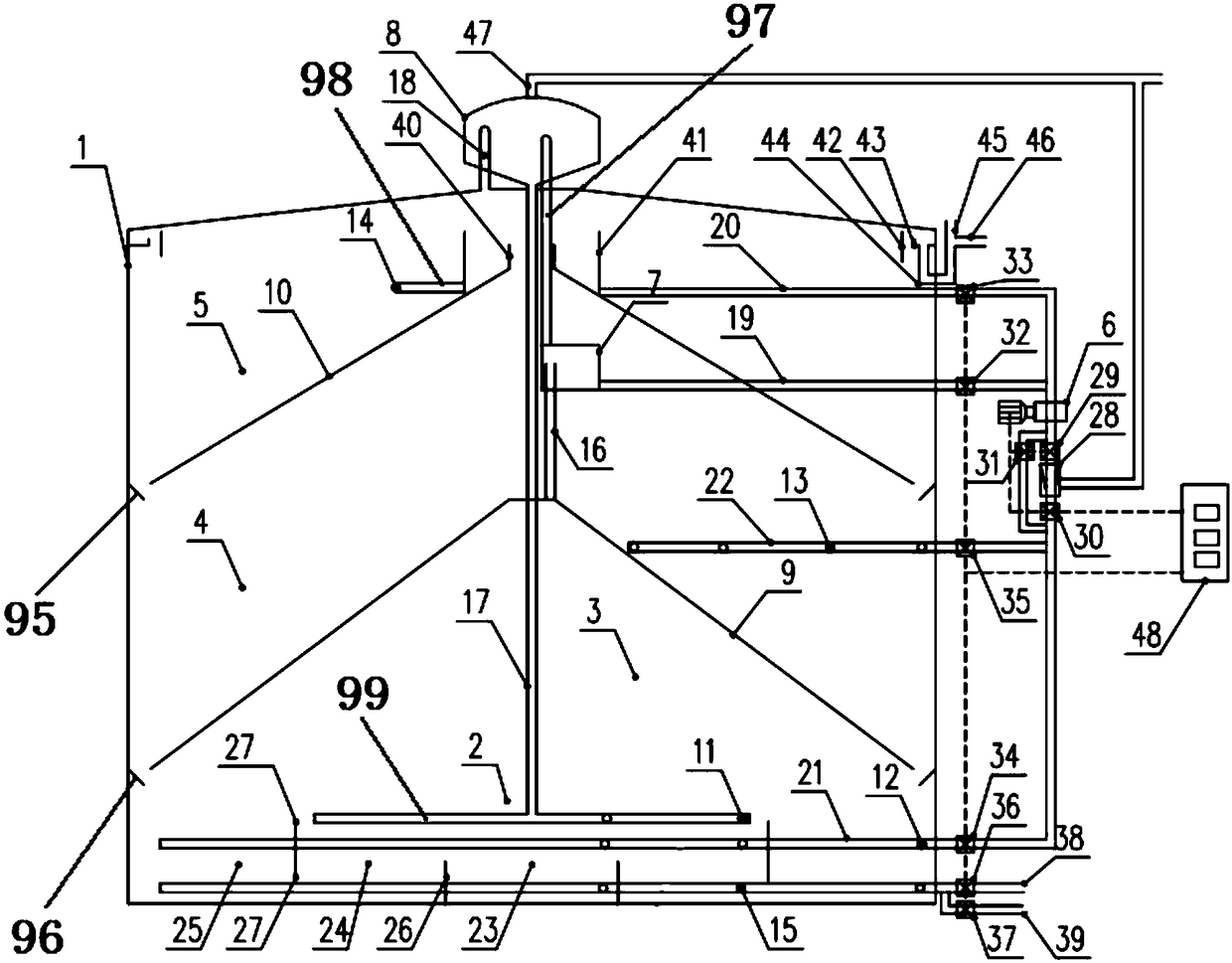

[0037] A multi-stage self-circulating anaerobic digestion reactor, the reactor includes a reactor including a tank body 1, an external circulation pump 6, a pipeline jet 28, an internal air-water separator 7, a top air-water separator 8, a first-stage three Phase separator 9, secondary three-phase separator 10, inner deflector 26, middle deflector 27, air-water separation baffle 41, slag retainer 42, overflow port 40, outlet weir 43, control system 48; Primary internal circulation nozzle 11, primary external circulation nozzle 12, secondary external circulation nozzle 13, secondary internal circulation nozzle 14, water inlet nozzle 15, first air lift riser 16, second air lift riser 97, backflow Pipe 17, air intake pipe 18, primary external circulation outlet pipe 19, secondary external circulation outlet pipe 20, primary external circulation inlet pipe 21, secondary external circulation inlet pipe 22, water inlet pipe 38, U-shaped outlet pipe 44, drain Empty port 45, drainage ...

Embodiment 2

[0052] The working method of described multistage self-circulation anaerobic digestion reactor,

[0053] During operation, the raw slag water is controlled by the opening and closing of the water inlet valve 36, and the water inlet nozzle 15 connected to the water inlet pipe 38 enters the water distribution mixing area 2. The water inlet is continuous water inlet or pulse water inlet, and the reactor is In combination with working conditions and water quality characteristics, it can adopt multi-stage internal self-circulation anaerobic digestion operation mode, external power-assisted multi-stage self-circulation anaerobic digestion operation mode or external power-assisted enhanced multi-stage self-circulation anaerobic digestion operation Any one of the modes or two or three alternate operating modes;

[0054]When the reactor works in the multi-stage internal self-circulation anaerobic digestion operation mode, the water inlet valve 36 is opened, and the raw slag water is in...

Embodiment 3

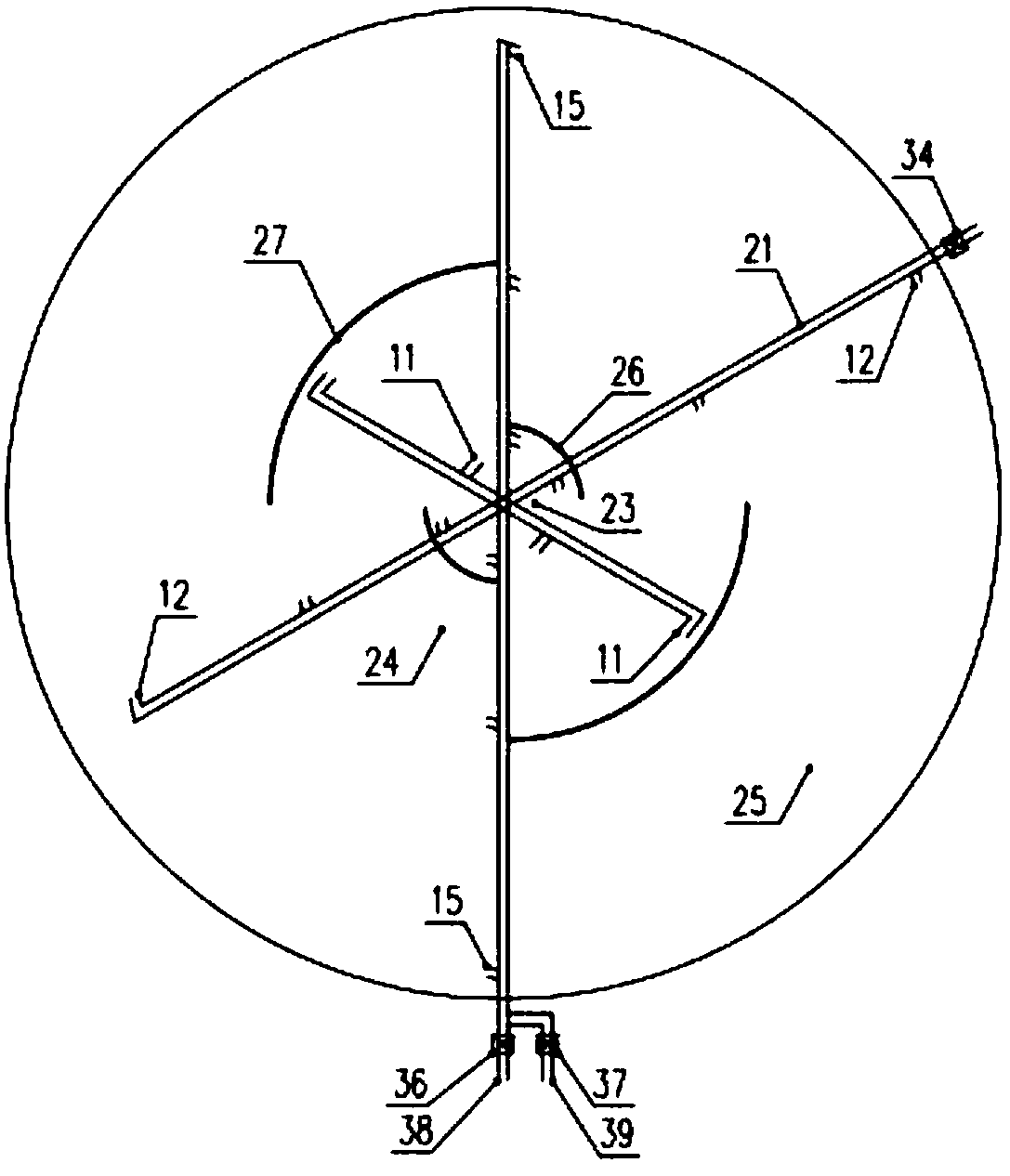

[0058] The water distribution mixing zone 2 is set from the lower part of the primary three-phase separator 9 in the primary reaction zone 3 to the bottom of the tank body 1, accounting for 1 / 8-1 / 6 of the height of the tank body 1, and is arranged in sequence from the center of the tank body 1 outward. There are inner swirling mixing area 23, middle swirling mixing area 24, and outer swirling mixing area 25. Internal swirling mixing area 23 and middle swirling mixing area 24 are provided with inner deflector 26 and middle deflector 27 respectively, and inner deflector 26 and The middle deflectors 27 are arc-shaped with the same center as the tank body 1, the number of the inner deflectors 26 and the middle deflectors 27 are ≥ 2 groups, and the lengths of the inner deflectors 26 and the middle deflectors 27 are ≤ 1 / 4 circle, the angle between the inner deflector 26 and the middle deflector 27 is arranged at an angle of ≤90°, they are evenly arranged in opposite directions, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com