Widening reforming rigidity matching system of hollow slab bridge

A technology of hollow slab bridges and hollow slabs, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as sudden changes in stiffness, achieve the effects of reducing vibration displacement difference, overcoming vibration asynchrony, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

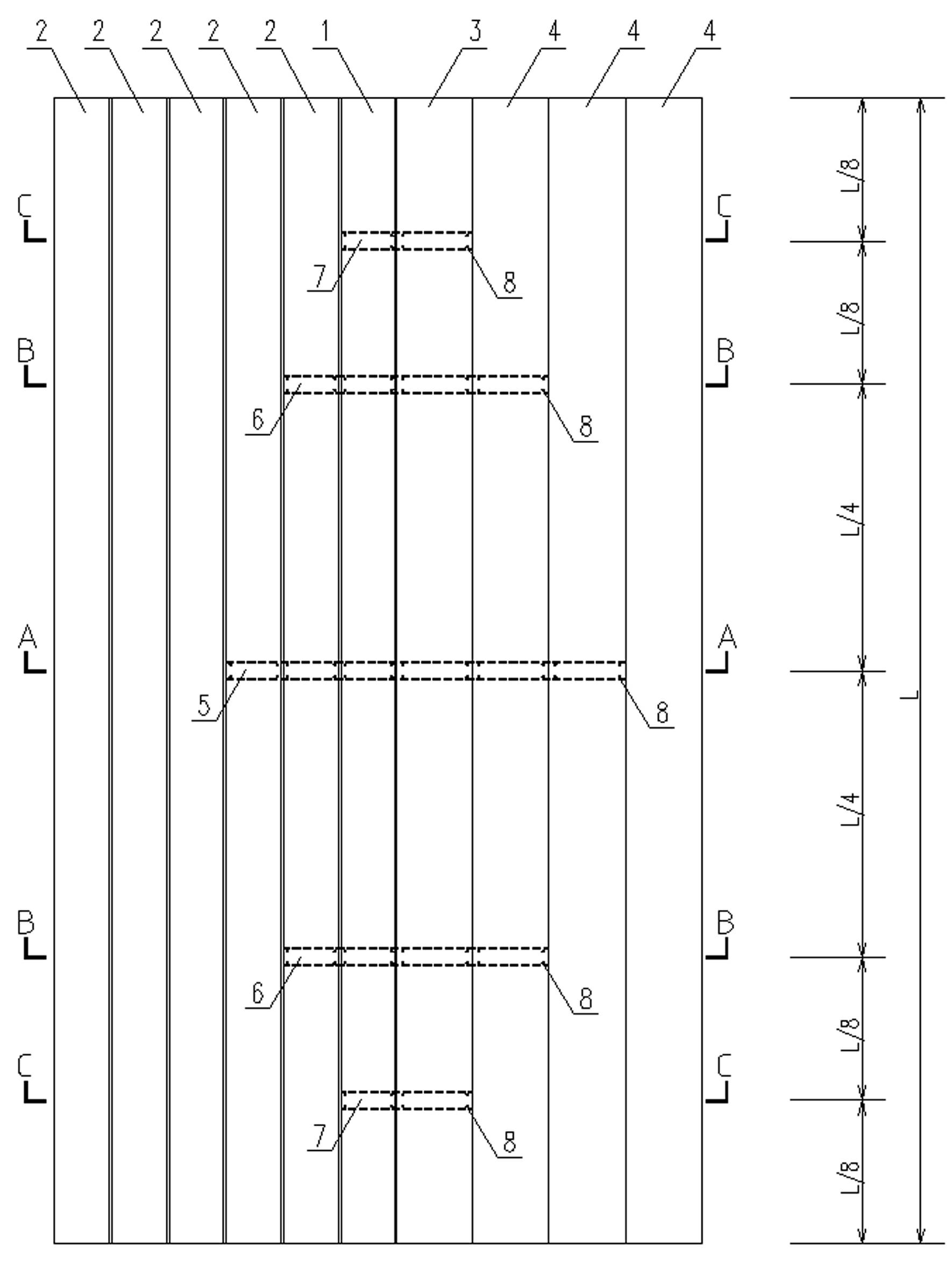

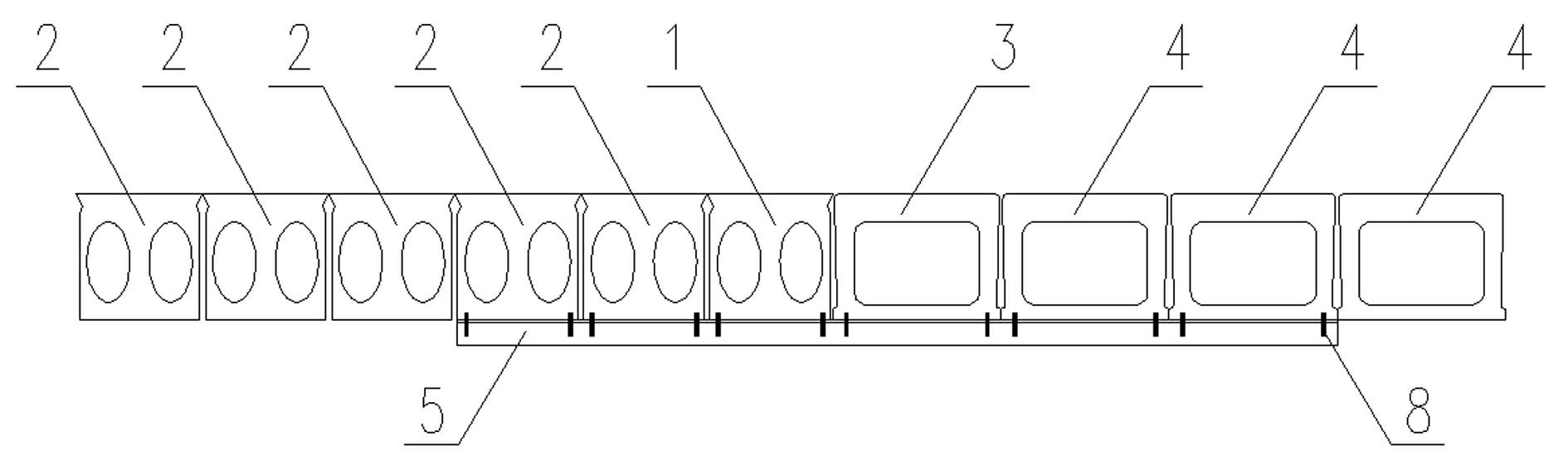

[0039] Such as figure 1 , image 3 , Figure 4 , Figure 5 As shown, a rigidity matching system for the widening and reconstruction of hollow slab bridges is suitable for the widening and reconstruction of hollow slab bridges with a span greater than 16m. Bridge, including the old hollow slab bridge side slab 1, the old hollow slab bridge inner slab 2, the new hollow slab bridge side slab 3, the new hollow slab bridge inner slab 4, the old hollow slab bridge side slab 1 and the new hollow slab bridge side slab 3 can be connected by the upper bridge deck pavement connection, or the longitudinal expansion joint connection, or the horizontal connection method of the cast-in-place wet joint connection.

[0040] A total of 5 stiffness matching members 5, 6, 7 are arranged along the transverse direction of the bridge, including the stiffness matching member 5 arranged at the mid-span position, the stiffness matching member 6 arranged at a position L / 4 from the end, and the stiffn...

Embodiment 2

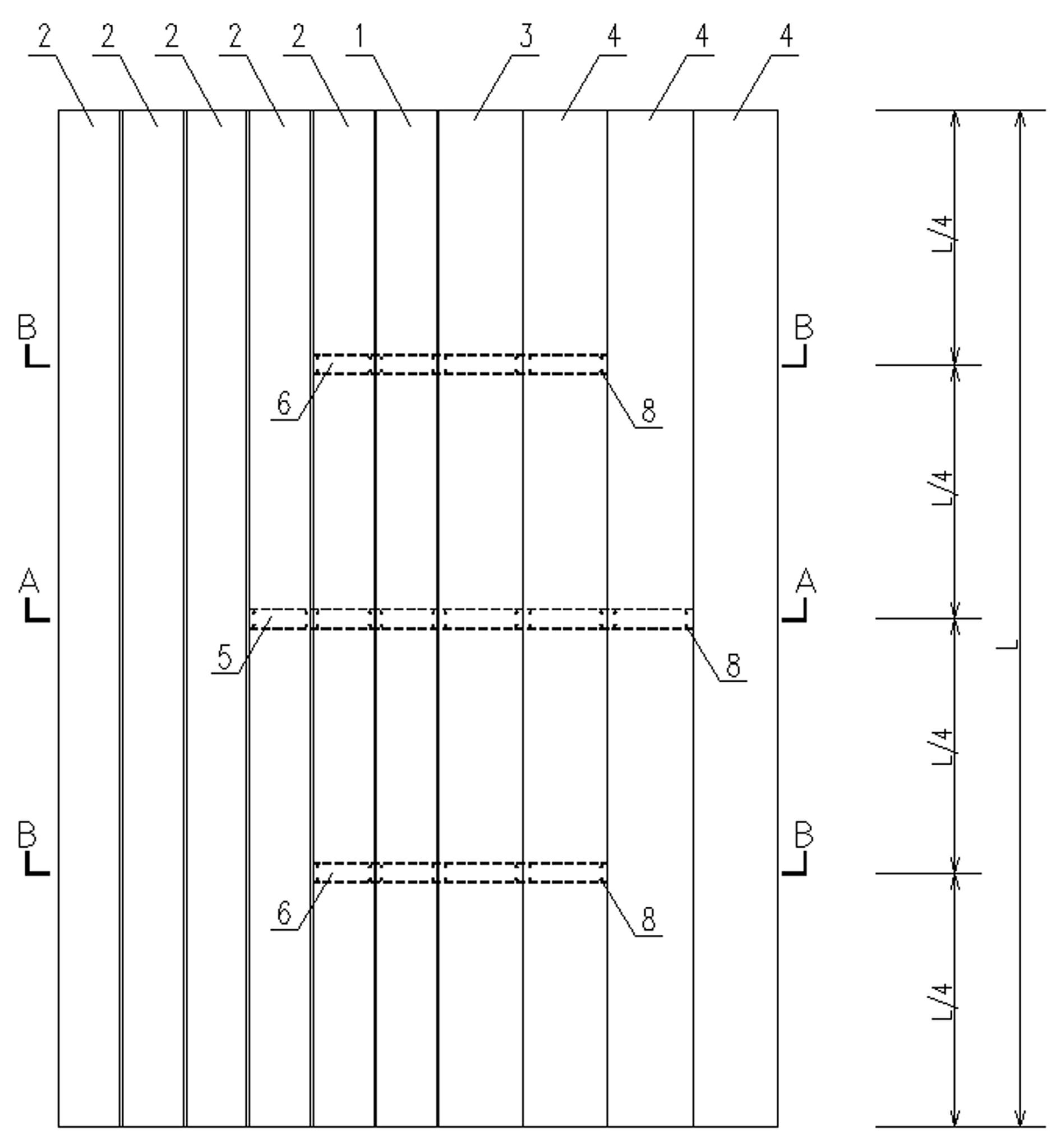

[0050] Such as figure 2 , image 3 As shown, a hollow slab bridge widening and reconstruction stiffness matching system is suitable for the widening and reconstruction of hollow slab bridges with a span less than or equal to 16m. New bridge, including the old hollow slab bridge side plate 1, the old hollow slab bridge inner plate 2, the new hollow slab bridge side plate 3, the new hollow slab bridge inner plate 4, at the old hollow slab bridge side plate 1 and the new hollow slab bridge edge The boards 3 can be connected by pavement on the upper part of the bridge, or provided with longitudinal expansion joints, or horizontally connected by cast-in-place wet joints.

[0051] A total of 3 stiffness matching members 5 and 6 are arranged along the transverse direction of the bridge, including the stiffness matching member 5 arranged at the mid-span position and the stiffness matching member 6 arranged at a position L / 4 from the end. The stiffness matching members 5 and 6 are ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com