Design and Construction Method of Reinforced Concrete Retaining Wall

A technology of reinforced concrete and construction methods, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as increasing project cost, reducing project cost, and large height difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Best practice:

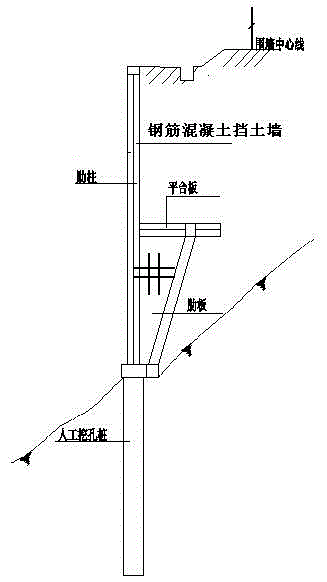

[0024] Refer to attached figure 1 , the design and construction method of reinforced concrete retaining wall, including the following steps:

[0025] 1. Calculate the design height of the segmented soil wall slab based on the actual situation of the site and the performance of the filler and the required height of the overall reinforced concrete retaining wall, so as to reasonably plan the number, elevation, length and thickness of the balance slab;

[0026] 2. Carry out foundation construction on reinforced concrete wall panels;

[0027] 3. Pouring the first section of reinforced concrete wall panels and rib columns at a set height, and filling the back of the wall: including compacting, making filter and drain holes, and leveling the back filling of the wall;

[0028] 4. Provide the first balance board, which includes a platform board and ribs. The balance board is installed on the side of the second reinforced concrete wall panel fill, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com